- umAfrika

- Isi-Albania

- Isi-Amharic

- Isi-Arabhu

- Isi-Armenian

- Isi-Azerbaijani

- Isi-Basque

- IsiBelarusian

- Isi-Bengali

- Isi-Bosnia

- IsiBulgaria

- IsiCatalan

- Cebuano

- China

- I-China (Taiwan)

- IsiCorsican

- IsiCroatia

- IsiCzech

- Isi-Danish

- IsiDashi

- IsiNgisi

- Isi-Esperanto

- Isi-Estonian

- IsiFinnish

- IsiFulentshi

- IsiFrisian

- IsiGalicia

- IsiGeorgia

- IsiJalimane

- isiGreki

- IsiGujarati

- IsiCreole saseHaiti

- hausa

- isi-hawaiian

- IsiHebheru

- Cha

- Miao

- IsiHungary

- Isi-Icelandic

- igbo

- Isi-Indonesian

- i-irish

- IsiNtaliyane

- IsiJapane

- Isi-Javanese

- Isi-Kannada

- kazakh

- I-Khmer

- IsiRwanda

- IsiKorea

- IsiKurdish

- IsiKyrgyz

- I-TB

- IsiLatini

- Isi-Latvian

- Isi-Lithuanian

- Isi-Luxembourgish

- IsiMacedonian

- UMalgashi

- Isi-Malay

- Isi-Malayalam

- IsiMaltese

- IsiMaori

- IsiMarathi

- IsiMongolia

- eMyanmar

- IsiNepali

- IsiNorwegian

- IsiNorwegian

- Isi-Occitan

- Isi-Pashto

- isiPheresiya

- IsiPolish

- IsiPutukezi

- IsiPunjabi

- IsiRomania

- IsiRashiya

- IsiSamoa

- IsiScottish Gaelic

- IsiSerbia

- IsiNgisi

- IsiShona

- Sindhi

- IsiSinhala

- IsiSlovak

- IsiSlovenian

- eSomalia

- ISpanishi

- IsiSundanese

- IsiSwahili

- IsiSwidi

- IsiTagalog

- Isi-Tajik

- IsiTamil

- IsiTatar

- Isi-Telugu

- IsiThai

- IsiTurkey

- IsiTurkmen

- Isi-Ukraine

- Isi-Urdu

- Isi-Uighur

- Isi-Uzbek

- Isi-Vietnamese

- Isi-Welsh

- Usizo

- Isi-Yiddish

- IsiYoruba

- Zulu

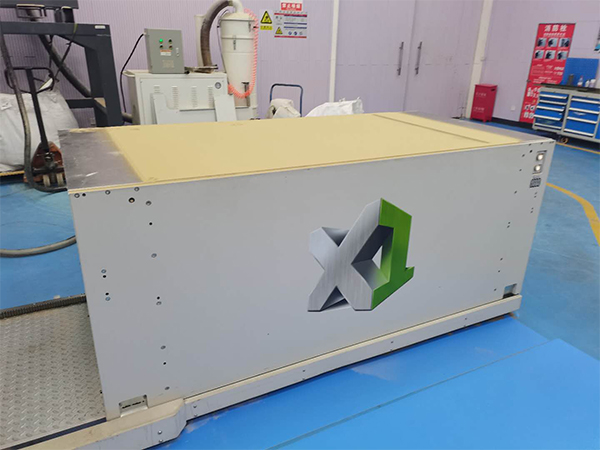

I-Ceramic casting sand yokuphrinta isihlabathi se-3d

I-Kaist sintered Ceramic sand, okuyimikhiqizo efanayo ne-Ceratec's Nagai Cerabeads, iwuhlobo lwesihlabathi se-ceramic foundry premium esisetshenziselwa ukwakha isikhunta nama-cores okukhipha insimbi imikhiqizo enenani eliphezulu ezimbonini zezimoto, zikawoyela negesi, izimayini nezokwakha. Lokho kuhlanganisa amabhulokhi amasilinda namavalvu asebenza ngogesi, kanye namaphampu, ama-impeller namathuluzi. Isihlabathi sokwenziwa se-Kaist senziwe ngamakristalu e-mullite anekhwalithi ezinzile ngokwedlulele. Akhiqizwa ngokudubula ama-granules ayindilinga, hhayi ngokuwachoboza.

Njengesihlabathi sokuphrinta kwe-3D okokusebenza, manje ozakwethu sebene-ExOne, Voxeljet, KOCEL, njll.

Impahla yesihlabathi seCeramic

| Ingxenye Yekhemikhali Eyinhloko | Al₂O₃≥53%, Fe₂O₃<4%, TiO₂<3%, SiO₂≤37% |

| Umumo Wokusanhlamvu | I-Spherical |

| I-Angular Coefficient | ≤1.1 |

| Usayizi Oyingxenye | 45μm -2000μm |

| I-Refractoriness | ≥1800℃ |

| Ukuminyana kwenqwaba | 1.5-1.6 g/cm3 |

| I-Thermal Expansion (RT-1200℃) | 4.5-6.5x10-6/k |

| Umbala | Isihlabathi |

| PH | 6.6-7.3 |

| Ukubunjwa kweMineralogical | I-Soft + Corundum |

| Izindleko ze-Acid | 1 ml/50g |

| LOI | <0.1% |

Inzuzo

Kaist ceramic foundry sand is about half as light as zircon and chromite, is about third as light as fused ceramic sand. Compared to these natural sand and other foundry media (the material is able to turn out about twice the number of molds per unit weight). Kaist ceramic foundry sand can deliver mold and core packages with a range of benefits that include higher-strength sand casting packages, with high heat resistance, low thermal expansion, improved final part resolution and a smoother surface finish. It can also be handled very easily, saving labor and transfer power costs. However, the manufacturer recommends paying attention to the amount of binder addition.

Isicelo

Ukusebenzisa isihlabathi se-Kaist Ceramic foundry futhi kunciphisa imfucuza nothuli, ngenani eliphakeme lokuphinda libuyiselwe lezinto. Ngaphezu kwalokho, isihlabathi se-Kaist Ceramic Foundry sesivele sisetshenziswa ezindaweni ezingaphezu kwe-100 emhlabeni jikelele; angasetshenziswa ezinqubweni zokwenza isikhunta esivamile ukuze alethe imiphumela yekhwalithi ephezulu ngohlu lwezinsimbi, okuhlanganisa izinsimbi (i-alloy ephansi, ikhabhoni, nestainless), insimbi (grey, ductile), i-aluminium, nezinye izinsimbi lapho ukulawula okuqinile. futhi kufiswa ukuqedwa kwendawo.

Izingxenye Zokusabalalisa Usayizi Wezinhlayiyana

Ukusabalalisa usayizi wezinhlayiyana kungenziwa egcizelele ngokuvumelana nemfuneko yakho.

|

I-Mesh |

20 | 30 | 40 | 50 | 70 | 100 | 140 | 200 | 270 | Ipani | I-AFS | |

|

μm |

850 | 600 | 425 | 300 | 212 | 150 | 106 | 75 | 53 | Ipani | ||

| Ikhodi | 70/140 | ≤5 | 25-35 | 35-50 | 8-15 | ≤5 | ≤1 | 65±4 | ||||

| 140/70 | ≤5 | 15-35 | 35-50 | 20-25 | ≤8 | ≤2 | 70±5 | |||||

| 100/200 | ≤10 | 20-35 | 35-50 | 15-20 | ≤10 | ≤2 | 110±5 | |||||

Izigaba zemikhiqizo