- Afrikaly

- Alban

- Amhar

- Arapça

- Ermeni

- Azerbaýjan

- Bask

- Belarus

- Bengali

- Bosniýa

- Bolgar

- Katalan

- Sebuano

- Hytaý

- Hytaý (Taýwan)

- Korsikan

- Horwatiýa

- Çeh

- Daniýaly

- Gollandiýaly

- Iňlis

- Esperanto

- Eston

- Fin

- Fransuz

- Frizian

- Galisiýa

- Gürji

- Nemes

- Grek

- Gujarati

- Gaiti kreoly

- hausa

- hawaiian

- Hebrewewreýçe

- .Ok

- Miao

- Wenger

- Islandiýa

- igbo

- Indoneziýaly

- irish

- Italýan

- Japaneseaponlar

- Javaneseawan

- Kannada

- Gazak

- Khmer

- Ruanda

- Koreýçe

- Kürt

- Gyrgyzystan

- Inçekesel

- Latyn

- Latwiýa

- Litwa

- Lýuksemburg

- Makedoniýa

- Malgaşi

- Malaý

- Malaýalam

- Malta

- Maori

- Marathi

- Mongol

- Mýanma

- Nepali

- Norweg

- Norweg

- Oksitan

- Puştun

- Pars

- Polýak

- Portugaliýa

- Penjebi

- Rumyn

- Rus

- Samoan

- Şotlandiýaly Gael

- Serb

- Iňlis

- Şona

- Sindhi

- Sinhala

- Slowakiýa

- Sloweniýa

- Somali

- Ispan

- Sundanese

- Suwaýili

- Şwesiýa

- Tagalog

- Täjik

- Tamil

- Tatar

- Telugu

- Taý

- Türk

- Türkmenler

- Ukrain

- Urdu

- Uýgur

- Özbek

- Wýetnamly

- Uels

- Kömek ediň

- Yiddishahudy

- Yorubaoruba

- Zulu

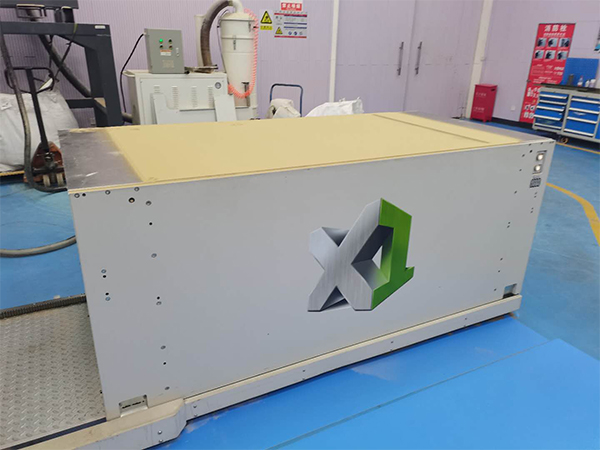

Gum 3d çap etmek üçin keramiki guýma çäge

Kaist süzülen keramiki gum, Ceratec-iň Nagai Cerabeads bilen birmeňzeş önümler, awtoulag, nebit-gaz, dag-magdan we gurluşyk pudaklarynda ýokary bahaly önümleri metal guýmak üçin galyplar we ýadro döretmek üçin ulanylýan premium keramiki guýma çäge görnüşidir. Oňa silindr bloklary we gidrawlik klapanlar, nasoslar, impellerler we gurallar girýär. Kaist emeli gum, gaty durnukly mullit kristallaryndan ýasalýar. Olary ezmek bilen däl-de, sferik granulalary atmak arkaly öndürilýär.

Çäge 3D çap ediji çig mal hökmünde, indi hyzmatdaşlarymyzda ExOne, Voxeljet, KOCEL we ş.m. köp

Keramiki çägäniň eýeçiligi

| Esasy himiki komponent | Al₂O₃≥53%, Fe₂O₃ < 4%, TiO₂ < 3%, SiO₂≤37% |

| Galla şekili | Sferik |

| Burç koeffisiýenti | ≤1.1 |

| Bölekleýin ululyk | 45μm -2000μm |

| Döwülme | ≥1800 ℃ |

| Köp dykyzlygy | 1,5-1,6 g / cm3 |

| Malylylyk giňelişi (RT-1200 ℃) | 4.5-6.5x10-6 / k |

| Reňk | Gum |

| PH | 6.6-7.3 |

| Mineralogiki düzümi | Softumşak + korund |

| Kislotanyň bahasy | < 1 ml / 50g |

| LOI | < 0,1% |

Üstünlik

Kaist ceramic foundry sand is about half as light as zircon and chromite, is about third as light as fused ceramic sand. Compared to these natural sand and other foundry media (the material is able to turn out about twice the number of molds per unit weight). Kaist ceramic foundry sand can deliver mold and core packages with a range of benefits that include higher-strength sand casting packages, with high heat resistance, low thermal expansion, improved final part resolution and a smoother surface finish. It can also be handled very easily, saving labor and transfer power costs. However, the manufacturer recommends paying attention to the amount of binder addition.

Arza

Kaist keramiki guýma çäge ulanmak, materiallaryň ýokary meliorasiýa gymmaty bilen galyndylary we tozany hem azaldar. Mundan başga-da, Kaist keramiki guýma çägeleri eýýäm dünýädäki 100-den gowrak zawodda ulanylýar; polat (pes erginli, uglerod we poslamaýan), demir (çal, süýümli), alýumin we berk gözegçilikde saklanýan beýleki metallar bilen ýokary hilli netijeleri bermek üçin adaty galyndy öndürmek prosesinde ulanylyp bilner. we ýerüsti gutarmak islenýär.

Bölejikleriň ululygynyň paýlanyşy

Bölejikleriň ululygyny paýlamak islegiňize görä düzülip bilner.

|

Meş |

20 | 30 | 40 | 50 | 70 | 100 | 140 | 200 | 270 | Pan | AFS | |

|

μm |

850 | 600 | 425 | 300 | 212 | 150 | 106 | 75 | 53 | Pan | ||

| Kod | 70/140 | ≤5 | 25-35 | 35-50 | 8-15 | ≤5 | ≤1 | 65 ± 4 | ||||

| 140/70 | ≤5 | 15-35 | 35-50 | 20-25 | ≤8 | ≤2 | 70 ± 5 | |||||

| 100/200 | ≤10 | 20-35 | 35-50 | 15-20 | ≤10 | ≤2 | 110 ± 5 | |||||

Önüm kategoriýalary