- afrikalik

- alban

- Amhar

- arabcha

- arman

- ozarbayjon

- bask

- belarus

- bengal

- bosniyalik

- bolgar

- katalan

- Sebuano

- Xitoy

- Xitoy (Tayvan)

- Korsika

- xorvat

- chex

- Daniya

- golland

- Ingliz

- Esperanto

- eston

- fin

- frantsuz

- frizcha

- Galisian

- gruzin

- nemis

- yunoncha

- Gujarati

- Gaiti kreoli

- hausa

- gavayilik

- ibroniy

- yoq

- Miao

- venger

- island

- igbo

- indonez

- irland

- italyancha

- yapon

- yava

- Kannada

- qozoq

- kxmer

- Ruanda

- koreys

- kurd

- qirg'iz

- sil kasalligi

- lotin

- latviyalik

- litva

- Lyuksemburg

- makedon

- Malgashi

- malay

- Malayalam

- malta

- maori

- Marathi

- mo'g'ul

- Myanma

- Nepal

- norveg

- norveg

- oksitan

- Pushtu

- forscha

- polyak

- portugal

- panjob

- rumin

- rus

- Samoa

- Shotlandiya gael tili

- serb

- Ingliz

- Shona

- Sindhi

- Sinhala

- slovak

- sloven

- Somali

- ispancha

- sundan

- suahili

- shved

- Tagalog

- tojik

- Tamil

- tatar

- Telugu

- tay

- turkcha

- turkman

- ukrain

- urdu

- uyg'ur

- o'zbek

- Vetnam

- uels

- Yordam

- Yahudiy

- Yoruba

- Zulu

Qum 3D bosib chiqarish uchun keramik quyma qum

Ceratec's Nagai Cerabeads bilan bir xil mahsulotlar bo'lgan Kaist sinterlangan keramik qum avtomobilsozlik, neft va gaz, tog'-kon sanoati va qurilish sanoatida qimmatbaho mahsulotlarni metall quyish uchun qoliplar va yadrolarni yaratish uchun ishlatiladigan yuqori sifatli keramik quyish qumining bir turidir. Bunga silindr bloklari va gidravlik klapanlar, shuningdek nasoslar, pervanellar va asboblar kiradi. Kaist sun'iy qum juda barqaror sifatga ega mullit kristallaridan qilingan. Ular sferik granulalarni maydalash orqali emas, balki ularni yoqish orqali ishlab chiqariladi.

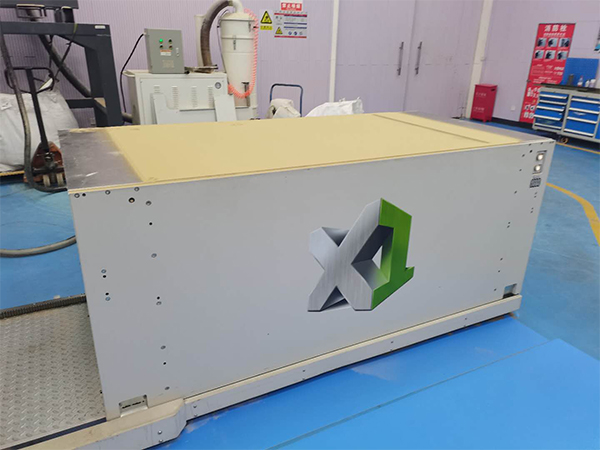

Qum 3D bosib chiqarish xomashyosi sifatida endi bizning hamkorlarimiz ExOne, Voxeljet, KOCEL va boshqalarga ega.

Seramika qum mulki

| Asosiy kimyoviy komponent | Al₂O₃≥53%, Fe₂O₃<4%, TiO₂<3%, SiO₂≤37% |

| Don shakli | Sferik |

| Burchak koeffitsienti | ≤1.1 |

| Qisman hajmi | 45mkm -2000mkm |

| O'tga chidamlilik | ≥1800 ℃ |

| Ommaviy zichlik | 1,5-1,6 g/sm3 |

| Termal kengayish (RT-1200 ℃) | 4,5-6,5x10-6/k |

| Rang | Qum |

| PH | 6.6-7.3 |

| Mineralogik tarkibi | Yumshoq + korund |

| Kislota narxi | <1 ml/50g |

| LOI | <0,1% |

Afzallik

Kaist ceramic foundry sand is about half as light as zircon and chromite, is about third as light as fused ceramic sand. Compared to these natural sand and other foundry media (the material is able to turn out about twice the number of molds per unit weight). Kaist ceramic foundry sand can deliver mold and core packages with a range of benefits that include higher-strength sand casting packages, with high heat resistance, low thermal expansion, improved final part resolution and a smoother surface finish. It can also be handled very easily, saving labor and transfer power costs. However, the manufacturer recommends paying attention to the amount of binder addition.

Ilova

Kaist keramik quyish qumidan foydalanish, shuningdek, materiallarning yuqori meliorativ qiymati bilan chiqindilar va changni kamaytiradi. Bundan tashqari, Kaist seramika quyish qumi allaqachon butun dunyo bo'ylab 100 dan ortiq quyish zavodlarida qo'llaniladi; Ular an'anaviy mog'or ishlab chiqarish jarayonlarida turli metallar, jumladan, po'lat (past qotishma, uglerod va zanglamaydigan), temir (kulrang, egiluvchan), alyuminiy va qattiq nazorat qilinadigan boshqa metallar bilan yuqori sifatli natijalarni berish uchun ishlatilishi mumkin. va sirt qoplamasi talab qilinadi.

Zarrachalar hajmining taqsimoti qismlari

Zarrachalar hajmini taqsimlash sizning talabingizga muvofiq sozlanishi mumkin.

|

Mesh |

20 | 30 | 40 | 50 | 70 | 100 | 140 | 200 | 270 | Pan | AFS | |

|

mkm |

850 | 600 | 425 | 300 | 212 | 150 | 106 | 75 | 53 | Pan | ||

| Kod | 70/140 | ≤5 | 25-35 | 35-50 | 8-15 | ≤5 | ≤1 | 65±4 | ||||

| 140/70 | ≤5 | 15-35 | 35-50 | 20-25 | ≤8 | ≤2 | 70±5 | |||||

| 100/200 | ≤10 | 20-35 | 35-50 | 15-20 | ≤10 | ≤2 | 110±5 | |||||

Mahsulot toifalari