- Afrikaan

- Albaaniyaan

- Amxaari

- Carabi

- Armeeniyaan

- Asarbayjaan

- Basque

- Belarusiyaanka

- Bengali

- Bosnia

- Bulgaariya

- Catalan

- Cebuano

- Shiinaha

- Shiinaha (Taiwan)

- Korsican

- Croatian

- Czech

- Danish

- Dutch

- Ingiriis

- Esperanto

- Istooniyaan

- Finnish

- Faransiis

- Frisian

- Galiciyan

- Joorjiyaan

- Jarmal

- Giriig

- Gujarati

- Haitian Creole

- hausa

- hawiye

- Cibraaniga

- Maya

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- iriish

- Talyaani

- Jabbaan

- Javanese

- Kannada

- Kazakh

- Khmer

- Ruwanda

- Kuuriyaan

- Kurdish

- Kyrgyz

- Qaaxo

- Laatiinka

- Latvia

- Lithuanian

- Luxembourgish

- Masedooniyaan

- Malgashi

- Malaay

- Malayalam

- Malta

- Maori

- Marathi

- Mongoliyaan

- Myanmar

- Nepali

- Noorwiiji

- Noorwiiji

- Occitan

- Pashto

- Faaris

- Polish

- Boortaqiis

- Punjabi

- Romanian

- Ruush

- Samoan

- Scottish Gaelic

- Seerbiyaan

- Ingiriis

- Shona

- Sindhi

- Sinhala

- Slovakia

- Islovenian

- Somali

- Isbaanish

- Sundanese

- Sawaaxili

- Iswidish

- Tagalog

- Taajik

- Tamil

- Tataarka

- Telugu

- Thai

- Turki

- Turkmen

- Yukreeniyaan

- Urduu

- Uighur

- Uzbekistan

- Vietnamese

- Welsh

- I caawi

- Yiddish

- Yurub

- Zulu

Ciidda tuurista dhoobada ee ciidda daabacaadda 3d

Ciidda Kaist sintered Ceramic ciid, oo la mid ah alaabta Ceratec's Nagai Cerabeads, waa nooc ka mid ah ciid alwaaxyada dhoobada ah ee qaaliga ah ee loo isticmaalo in lagu abuuro caaryada iyo koofiyadaha birta lagu shubo alaab qiimo sare leh ee baabuurta, saliidda & gaaska, macdanta iyo warshadaha dhismaha. Taas waxaa ka mid ah baloogyada dhululubada iyo mashiinnada biyaha, iyo sidoo kale bambooyin, mashiinnada iyo qalabka. Ciidda macmalka ah ee Kaist waxay ka samaysan yihiin kiristaalo mullite ah oo leh tayo aad u deggan. Waxaa lagu soo saaraa in la rido granules wareegsan, ma aha in la burburiyo.

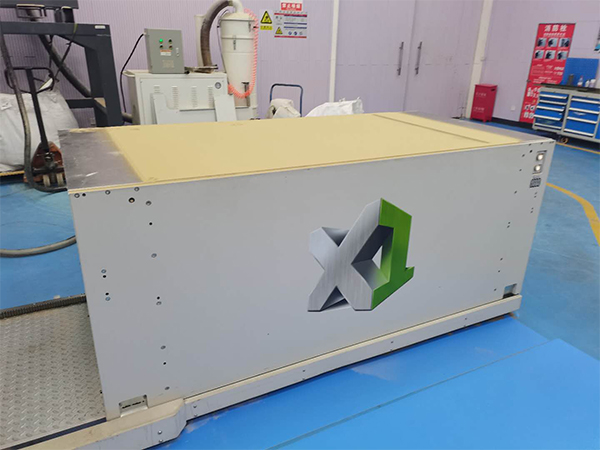

Sida ciidda 3D daabacaadda alaabta ceeriin, hadda la-hawlgalayaasheenna waxay leeyihiin ExOne, Voxeljet, KOCEL, iwm.

Hantida Ciidda dhoobada

| Qaybta Kiimikada ugu weyn | Al₂O₃≥53%, Fe₂O₃<4%, TiO₂<3%, SiO₂≤37% |

| Qaabka hadhuudhka | Goobaysan |

| Iskuxidhka xagal | ≤1.1 |

| Cabirka Qayb ahaan | 45μm -2000μm |

| Refractority | ≥1800℃ |

| Cufnaanta Bulk | 1.5-1.6 g/cm3 |

| Balaadhinta kulaylka (RT-1200℃) | 4.5-6.5x10-6/k |

| Midabka | Ciid |

| PH | 6.6-7.3 |

| Halabuurka macdanta | Jilicsan + Corundum |

| Qiimaha aysiidhka | 1 ml/50g |

| LOI | 0.1% |

Faa'iidada

Kaist ceramic foundry sand is about half as light as zircon and chromite, is about third as light as fused ceramic sand. Compared to these natural sand and other foundry media (the material is able to turn out about twice the number of molds per unit weight). Kaist ceramic foundry sand can deliver mold and core packages with a range of benefits that include higher-strength sand casting packages, with high heat resistance, low thermal expansion, improved final part resolution and a smoother surface finish. It can also be handled very easily, saving labor and transfer power costs. However, the manufacturer recommends paying attention to the amount of binder addition.

Codsiga

Isticmaalka ciid ka samaysan dhoobada Kaist waxay sidoo kale yaraynaysaa qashinka iyo boodhka, oo leh qiimaha dib u soo celinta alaabta. Intaa waxaa dheer, ciid ka samaysan dhoobada Kaist ayaa horeyba loogu isticmaalay in ka badan 100 aasaaska adduunka oo dhan; waxaa loo isticmaali karaa hababka samaynta caaryada dhaqameed si ay u bixiyaan natiijooyin tayo sare leh oo leh noocyo kala duwan oo biro ah, oo ay ku jiraan birta (daawaha hoose, kaarboon, iyo aan lahayn), birta (cawlan, ductile), aluminium, iyo biraha kale halkaasoo xakamaynta adag oo dusha sare la dhammeeyo ayaa la rabaa.

Qaybaha Cabbirka Qaybaha Qaybinta

Qaybinta cabbirka walxaha waxaa lagu habeyn karaa iyadoo loo eegayo baahidaada.

|

Mesh |

20 | 30 | 40 | 50 | 70 | 100 | 140 | 200 | 270 | digsi | AFS | |

|

μm |

850 | 600 | 425 | 300 | 212 | 150 | 106 | 75 | 53 | digsi | ||

| Koodhka | 70/140 | ≤5 | 25-35 | 35-50 | 8-15 | ≤5 | ≤1 | 65±4 | ||||

| 140/70 | ≤5 | 15-35 | 35-50 | 20-25 | ≤8 | ≤2 | 70±5 | |||||

| 100/200 | ≤10 | 20-35 | 35-50 | 15-20 | ≤10 | ≤2 | 110±5 | |||||

Qaybaha alaabta