- Moafrika

- Sealbania

- Seamharic

- Searabia

- Searmenia

- Se-Azerbaijani

- Sebasque

- Sebelarusia

- Benghali

- Sebosnia

- Se-Bulgaria

- Secatalan

- Sebuano

- China

- China (Taiwan)

- Corsican

- Secroatia

- Czech

- Sedanishe

- Se-Dutch

- Senyesemane

- Esperanto

- Seestonia

- Sefinnishe

- Sefora

- Sefrisia

- Segalician

- Segeorgia

- Sejeremane

- Segerike

- Segujarati

- Secreole sa Haiti

- hausa

- siwaiian

- Seheberu

- Che

- Miao

- Se-Hungary

- Seiceland

- igbo

- Seindonesia

- irish

- Setaliana

- Sejapane

- Se-Javanese

- Kannada

- kazakh

- Khmer

- Rwanda

- Sekorea

- Sekurdish

- Sekyrgyz

- Lefuba

- Selatine

- Selatvia

- Selithuania

- Se-Luxembourgish

- Semacedonia

- Malgashi

- Semalay

- Semalayalam

- Semalta

- Semaori

- Marathi

- Mongolian

- Myanmar

- tsa Nepali

- Norwegian

- Norwegian

- Occitan

- Sepashto

- Sepersia

- Sepolishe

- Sepotoketsi

- Sepunjabi

- Seromania

- Serussia

- Sesamoa

- Segaeli sa Scotland

- Seserbia

- Senyesemane

- Seshona

- Sindhi

- Sesinhala

- Seslovak

- Seslovenia

- Somalia

- Sepanish

- Sesundanese

- Seswahili

- Seswedishe

- Setagalog

- Se-Tajik

- Setamil

- Setatare

- Setelugu

- Sethai

- Se-Turkey

- Turkmen

- Seukraine

- Seurdu

- Uighur

- Seuzbek

- Sevietnam

- Welsh

- Thusa

- Yiddish

- Yoruba

- Sezulu

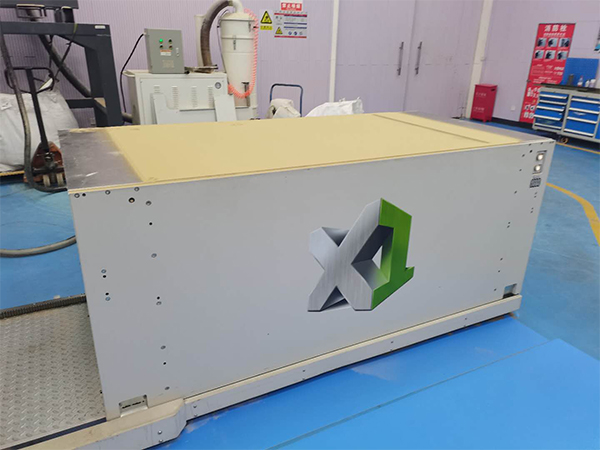

Ceramic casting sand bakeng sa lehlabathe 3d khatiso

Kaist sintered Ceramic sand, e leng tsona lihlahisoa tse tšoanang le Ceratec's Nagai Cerabeads, ke mofuta oa lehlabathe la premium ceramic foundry le sebelisetsoang ho etsa hlobo le li-cores bakeng sa lihlahisoa tsa tšepe tsa boleng bo phahameng indastering ea likoloi, oli le khase, merafo le kaho. Seo se kenyelletsa li-cylinder blocks le li-valve tsa hydraulic, hammoho le lipompo, li-impellers le lisebelisoa. Lehlabathe la maiketsetso la Kaist le entsoe ka likristale tsa mullite tse nang le boleng bo tsitsitseng haholo. Li hlahisoa ka ho thunya li-granules tse chitja, eseng ka ho li pshatla.

Joalo ka lisebelisoa tse tala tsa lehlabathe la 3D, joale balekane ba rona ba na le ExOne, Voxeljet, KOCEL, joalo-joalo.

Thepa ea Lehlabathe la Ceramic

| Karolo e ka Sehloohong ea Lik'hemik'hale | Al₂O₃≥53%, Fe₂O₃<4%, TiO₂<3%, SiO₂≤37% |

| Sebopeho sa lijo-thollo | Spherical |

| Angular Coefficient | ≤1.1 |

| Boholo bo sa Lekaneng | 45μm -2000μm |

| Refractoriness | ≥1800℃ |

| Boima ba Bongata | 1.5-1.6 g/cm3 |

| Katoloso ea Thermal (RT-1200℃) | 4.5-6.5x10-6/k |

| Mmala | Lehlabathe |

| PH | 6.6-7.3 |

| Sebopeho sa Mineralogical | E bonolo + Corundum |

| Litšenyehelo tsa Asiti | <1 ml/50g |

| LOI | <0.1% |

Molemo

Kaist ceramic foundry sand is about half as light as zircon and chromite, is about third as light as fused ceramic sand. Compared to these natural sand and other foundry media (the material is able to turn out about twice the number of molds per unit weight). Kaist ceramic foundry sand can deliver mold and core packages with a range of benefits that include higher-strength sand casting packages, with high heat resistance, low thermal expansion, improved final part resolution and a smoother surface finish. It can also be handled very easily, saving labor and transfer power costs. However, the manufacturer recommends paying attention to the amount of binder addition.

Kopo

Ho sebelisa lehlabathe la motheo la Kaist ceramic ho boetse ho fokotsa litšila le lerōle, ka boleng bo phahameng ba ho khutlisa thepa. Ho feta moo, lehlabathe la Kaist ceramic foundry le se le ntse le sebelisoa libakeng tse fetang 100 lefatšeng ka bophara; li ka sebelisoa mekhoeng ea setso ea ho etsa hlobo ho fana ka liphetho tsa boleng bo holimo ka mefuta e mengata ea litšepe, ho kenyeletsoa litšepe (alloy e tlase, k'habone, le stainless), tšepe (bohlooho, ductile), aluminium, le litšepe tse ling moo taolo e thata. 'me ho batloa bokaholimo.

Likarolo tsa Kabo ea boholo ba Particle

Kabo ea boholo ba phatsa e ka etsoa ho latela tlhoko ea hau.

|

Mesh |

20 | 30 | 40 | 50 | 70 | 100 | 140 | 200 | 270 | Pan | AFS | |

|

μm |

850 | 600 | 425 | 300 | 212 | 150 | 106 | 75 | 53 | Pan | ||

| Khoutu | 70/140 | ≤5 | 25-35 | 35-50 | 8-15 | ≤5 | ≤1 | 65±4 | ||||

| 140/70 | ≤5 | 15-35 | 35-50 | 20-25 | ≤8 | ≤2 | 70±5 | |||||

| 100/200 | ≤10 | 20-35 | 35-50 | 15-20 | ≤10 | ≤2 | 110±5 | |||||

Lihlopha tsa lihlahisoa