- afrikanesch

- Albanesch

- Amharesch

- Arabesch

- Armenesch

- Aserbaidschan

- Baskesch

- wäissrussesch

- Bengalesch

- Bosnesch

- Bulgarescg

- katalanesch

- Cebuano

- China

- China (Taiwan)

- korsesch

- Kroatesch

- Tschechesch

- Dänesch

- Hollänesch

- Englesch

- esperanto

- Estonesch

- Finnesch

- Franséisch

- friesesch

- Galizesch

- Georgesch

- Däitsch

- Griichesch

- Gujarati

- Haitescht Creole

- Haussa

- Hawaianesch

- Hebräesch

- Nee

- Miao

- Ungaresch

- Islännesch

- igbo

- Indonesesch

- Iresch

- Italienesch

- Japanesch

- Javanesesch

- Kannada

- kasachesch

- Khmer

- Rwandaner

- Koreanesch

- kurdesch

- kirgisesch

- TB

- laténgesch

- Lettesch

- litauesch

- lëtzebuergesch

- Mazedonesch

- Malgashi

- Malaiesch

- Malajalam

- Maltesesch

- maoresch

- Marathi

- mongolesch

- Myanmar

- Nepalesesch

- Norweegesch

- Norweegesch

- Okzitanesch

- pashtu

- Persesch

- Polnesch

- Portugisesch

- pundschabi

- Rumänesch

- Russesch

- Samoan

- Schottesch Gaelesch

- serbesch

- Englesch

- Shona

- Sindhi

- Sinhala

- Slowakesch

- Slowenesch

- somalesch

- Spuenesch

- Sundanesesch

- Swahili

- Schweedesch

- Tagalog

- Tadschi

- Tamil

- Tataresch

- Telugu

- Thai

- tierkesch

- turkmenesch

- Ukrainesch

- Urdu

- Uighur

- Usbekesch

- Vietnamesesch

- Waliser

- Hëllef

- jiddesch

- Yoruba

- Zulu

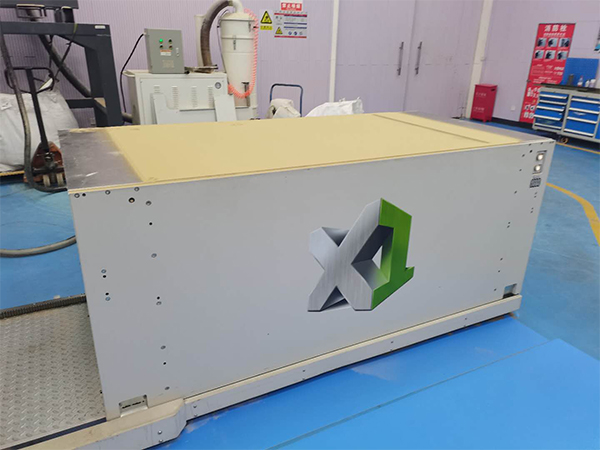

Keramik Gussand fir Sand 3D Dréckerei

Kaist gesintert Keramik Sand, dat ass déiselwecht Produkter mat Ceratec's Nagai Cerabeads, sinn eng Zort Premium Keramik Schmelz Sand benotzt fir Schimmel a Käre fir Metallgoss héichwäerteg Produkter an der Automobilindustrie, Ueleg & Gas, Biergbau a Bauindustrie ze kreéieren. Dat enthält Zylinderblocken an hydraulesch Ventile, souwéi Pompelen, Impelleren an Tools. Kaist kënschtlech Sand sinn aus Mullit Kristaller mat extrem stabil Qualitéit gemaach. Si gi produzéiert andeems se kugelfërmeg Granulat brennen, net andeems se se zerbriechen.

Als Sand 3D Dréckerei Rohmaterial, elo eis Partner ExOne, Voxeljet, KOCEL, etc.

Keramik Sand Property

| Main Chemeschen Komponent | Al₂O₃≥53%, Fe₂O₃<4%, TiO₂<3%, SiO₂≤37% |

| Grain Form | Kugelgestalt |

| Angular Koeffizient | ≤1.1 |

| Partiell Gréisst | 45 μm - 2000 μm |

| Refrakteritéit | ≥1800 ℃ |

| Bulk Dicht | 1.5-1.6 g/cm3 |

| Thermesch Expansioun (RT-1200 ℃) | 4.5-6.5x10-6/k |

| Faarf | Sand |

| PH | 6.6-7.3 |

| Mineralogesch Zesummesetzung | Soft + Korund |

| Saier Käschten | <1 ml/50 g |

| LOI | <0,1% |

Virdeel

Kaist ceramic foundry sand is about half as light as zircon and chromite, is about third as light as fused ceramic sand. Compared to these natural sand and other foundry media (the material is able to turn out about twice the number of molds per unit weight). Kaist ceramic foundry sand can deliver mold and core packages with a range of benefits that include higher-strength sand casting packages, with high heat resistance, low thermal expansion, improved final part resolution and a smoother surface finish. It can also be handled very easily, saving labor and transfer power costs. However, the manufacturer recommends paying attention to the amount of binder addition.

Applikatioun

Benotzt Kaist Keramik Schmelz Sand reduzéiert och Offall a Stëbs, mat héich reclamation Wäert vun de Materialien. Zousätzlech, Kaist Keramik Schmelz Sand sinn schonn op méi wéi 100 Schmelzen weltwäit benotzt; Si kënnen an traditionelle Schimmelprozesser benotzt ginn fir qualitativ héichwäerteg Resultater mat enger Rei vu Metaller ze liwweren, dorënner Stahlen (niddereg Legierung, Kuelestoff, an Edelstahl), Eisen (grau, duktil), Aluminium an aner Metaller, wou enk Kontroll ass. an Uewerfläch ass gewënscht.

Deeler vun Partikelgréisst Verdeelung

D'Partikelgréisst Verdeelung kann no Äre Besoinen personaliséiert ginn.

|

Mesh |

20 | 30 | 40 | 50 | 70 | 100 | 140 | 200 | 270 | Pan | AFS | |

|

μm |

850 | 600 | 425 | 300 | 212 | 150 | 106 | 75 | 53 | Pan | ||

| Code | 70/140 | ≤5 | 25-35 | 35-50 | 8-15 | ≤5 | ≤1 | 65±4 | ||||

| 140/70 | ≤5 | 15-35 | 35-50 | 20-25 | ≤8 | ≤2 | 70±5 | |||||

| 100/200 | ≤10 | 20-35 | 35-50 | 15-20 | ≤10 | ≤2 | 110±5 | |||||

Produit Kategorien