- Mwafrika

- Kialbeni

- Kiamhari

- Kiarabu

- Kiarmenia

- Kiazabajani

- Kibasque

- Kibelarusi

- Kibengali

- Kibosnia

- Kibulgaria

- Kikatalani

- Cebuano

- China

- Uchina (Taiwan)

- Kikosikani

- Kikroeshia

- Kicheki

- Kideni

- Kiholanzi

- Kiingereza

- Kiesperanto

- Kiestonia

- Kifini

- Kifaransa

- Kifrisia

- Kigalisia

- Kijojiajia

- Kijerumani

- Kigiriki

- Kigujarati

- Krioli ya Haiti

- hausa

- Kihawai

- Kiebrania

- Hapana

- Miao

- Kihungaria

- Kiaislandi

- igbo

- Kiindonesia

- irish

- Kiitaliano

- Kijapani

- Kijava

- Kikanada

- kazakh

- Khmer

- Mnyarwanda

- Kikorea

- Kikurdi

- Kirigizi

- TB

- Kilatini

- Kilatvia

- Kilithuania

- Kilasembagi

- Kimasedonia

- Malgashi

- Kimalei

- Kimalayalam

- Kimalta

- Kimaori

- Marathi

- Kimongolia

- Myanmar

- Kinepali

- Kinorwe

- Kinorwe

- Oksitani

- Kipashto

- Kiajemi

- Kipolandi

- Kireno

- Kipunjabi

- Kiromania

- Kirusi

- Kisamoa

- Kigaeli cha Kiskoti

- Kiserbia

- Kiingereza

- Kishona

- Kisindhi

- Kisinhala

- Kislovakia

- Kislovenia

- Msomali

- Kihispania

- Kisunda

- kiswahili

- Kiswidi

- Kitagalogi

- Tajiki

- Kitamil

- Kitatari

- Kitelugu

- Thai

- Kituruki

- Waturukimeni

- Kiukreni

- Kiurdu

- Uighur

- Kiuzbeki

- Kivietinamu

- Kiwelisi

- Msaada

- Kiyidi

- Kiyoruba

- Kizulu

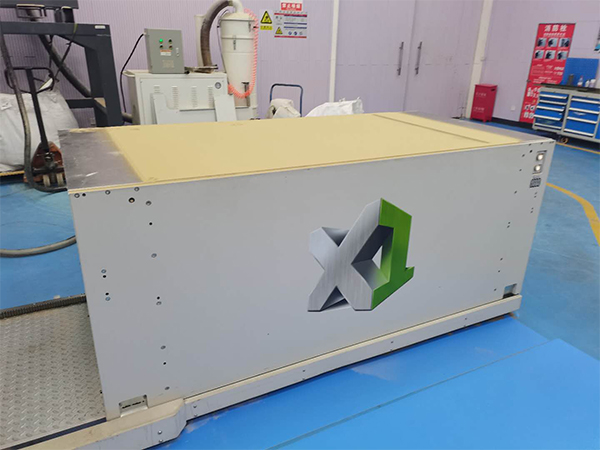

Mchanga wa kutupwa kauri kwa uchapishaji wa mchanga wa 3d

Kaist sintered Ceramic sand, ambayo ni bidhaa sawa na Ceratec's Nagai Cerabeads, ni aina ya mchanga wa msingi wa kauri unaotumiwa kuunda molds na cores kwa chuma cha kutupa bidhaa za thamani ya juu katika sekta ya magari, mafuta na gesi, madini na ujenzi. Hiyo ni pamoja na vitalu vya silinda na valves za majimaji, pamoja na pampu, impellers na zana. Mchanga bandia wa Kaist umetengenezwa kwa fuwele za mullite zenye ubora thabiti sana. Wao huzalishwa kwa kurusha chembechembe za spherical, si kwa kuziponda.

Kama nyenzo ghafi ya kuchapisha mchanga wa 3D, sasa washirika wetu wana ExOne, Voxeljet, KOCEL, nk.

Mali ya mchanga wa kauri

| Sehemu kuu ya Kemikali | Al₂O₃≥53%, Fe₂O₃<4%, TiO₂<3%, SiO₂≤37% |

| Umbo la Nafaka | Mviringo |

| Mgawo wa Angular | ≤1.1 |

| Ukubwa wa Sehemu | 45μm -2000μm |

| Kinzani | ≥1800℃ |

| Wingi Wingi | 1.5-1.6 g/cm3 |

| Upanuzi wa Joto (RT-1200℃) | 4.5-6.5x10-6/k |

| Rangi | Mchanga |

| PH | 6.6-7.3 |

| Muundo wa Madini | Laini + Corundum |

| Gharama ya Asidi | <1 ml/50g |

| LOI | <0.1% |

Faida

Kaist ceramic foundry sand is about half as light as zircon and chromite, is about third as light as fused ceramic sand. Compared to these natural sand and other foundry media (the material is able to turn out about twice the number of molds per unit weight). Kaist ceramic foundry sand can deliver mold and core packages with a range of benefits that include higher-strength sand casting packages, with high heat resistance, low thermal expansion, improved final part resolution and a smoother surface finish. It can also be handled very easily, saving labor and transfer power costs. However, the manufacturer recommends paying attention to the amount of binder addition.

Maombi

Kutumia mchanga wa msingi wa kauri wa Kaist pia hupunguza taka na vumbi, na thamani ya juu ya urekebishaji wa nyenzo. Kwa kuongeza, mchanga wa kauri wa Kaist tayari unatumika katika vituo zaidi ya 100 duniani kote; zinaweza kutumika katika michakato ya kitamaduni ya kutengeneza ukungu ili kutoa matokeo ya ubora wa juu na aina mbalimbali za metali, ikiwa ni pamoja na vyuma (aloi ya chini, kaboni, na pua), chuma (kijivu, ductile), alumini na metali nyingine ambapo udhibiti mkali. na kumaliza uso inahitajika.

Sehemu za Usambazaji wa ukubwa wa Chembe

Usambazaji wa ukubwa wa chembe unaweza kubinafsishwa kulingana na mahitaji yako.

|

Mesh |

20 | 30 | 40 | 50 | 70 | 100 | 140 | 200 | 270 | Panua | AFS | |

|

μm |

850 | 600 | 425 | 300 | 212 | 150 | 106 | 75 | 53 | Panua | ||

| Kanuni | 70/140 | ≤5 | 25-35 | 35-50 | 8-15 | ≤5 | ≤1 | 65±4 | ||||

| 140/70 | ≤5 | 15-35 | 35-50 | 20-25 | ≤8 | ≤2 | 70±5 | |||||

| 100/200 | ≤10 | 20-35 | 35-50 | 15-20 | ≤10 | ≤2 | 110±5 | |||||

Kategoria za bidhaa