- Afrikan

- Albaniż

- Amhariku

- Għarbi

- Armenjan

- Ażerbajġani

- Bask

- Belarussu

- Bengali

- Bosnijan

- Bulgaru

- Katalan

- Cebuano

- Iċ-Ċina

- Iċ-Ċina (Tajwan)

- Korsiku

- Kroat

- Ċek

- Daniż

- Olandiż

- Ingliż

- Esperanto

- Estonjan

- Finlandiż

- Franċiż

- Friżjan

- Galizjan

- Ġorġjan

- Ġermaniż

- Grieg

- Guġarati

- Kreol Ħaitjan

- hausa

- Ħawajjan

- Ebrajk

- Le

- Miao

- Ungeriż

- Iżlandiż

- igbo

- Indoneżjan

- Irlandiż

- Taljan

- Ġappuniż

- Ġavaniż

- Kannada

- każak

- Khmer

- Rwandan

- Korean

- Kurdi

- Kirgiż

- TB

- Latin

- Latvjan

- Litwan

- Lussemburgiż

- Maċedonjan

- Malgashi

- Malajan

- Malajalam

- Malti

- Maori

- Marathi

- Mongoljan

- Il-Mjanmar

- Nepaliż

- Norveġiż

- Norveġiż

- Oċċitan

- Pashto

- Persjan

- Pollakk

- Portugiż

- Punġabi

- Rumen

- Russu

- Samoan

- Galliku Skoċċiż

- Serb

- Ingliż

- Shona

- Sindhi

- Sinħaliż

- Slovakk

- Sloven

- Somali

- Spanjol

- Sundaniż

- Swaħili

- Svediż

- Tagalog

- Taġik

- Tamil

- Tatar

- Telugu

- Tajlandiż

- Tork

- Turkmeni

- Ukrain

- Urdu

- Uighur

- Użbek

- Vjetnamiż

- Welsh

- Għajnuna

- Jiddix

- Joruba

- Żulu

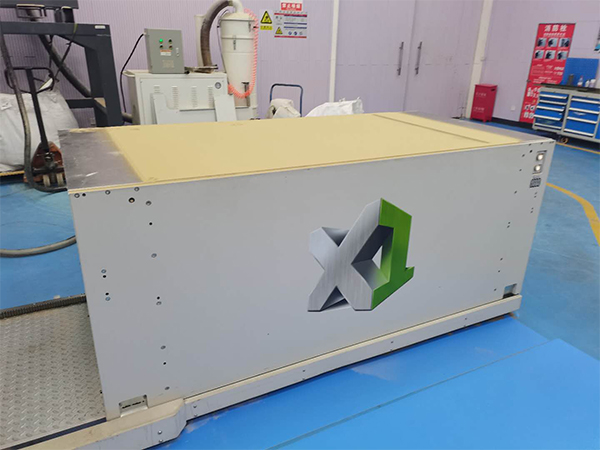

Ramel tal-ikkastjar taċ-ċeramika għall-istampar 3d tar-ramel

Kaist sinterizzat ramel taċ-ċeramika, li huwa l-istess prodotti ma 'Nagai Cerabeads ta' Ceratec, huma tip ta 'ramel tal-funderija taċ-ċeramika premium użat biex jinħolqu forom u qlub għall-ikkastjar tal-metall prodotti ta' valur għoli fl-industriji tal-karozzi, taż-żejt u tal-gass, tal-minjieri u tal-kostruzzjoni. Dan jinkludi blokki taċ-ċilindri u valvi idrawliċi, kif ukoll pompi, impellers u għodod. ramel artifiċjali Kaist huma magħmula minn kristalli mullite bi kwalità estremament stabbli. Huma prodotti billi jisparaw granuli sferiċi, mhux bit-tgħaffiġ tagħhom.

Bħala l-materja prima tal-istampar 3D tar-ramel, issa l-imsieħba tagħna għandhom ExOne, Voxeljet, KOCEL, eċċ.

Proprjetà tar-ramel taċ-ċeramika

| Komponent Kimiku Prinċipali | Al₂O₃≥53%, Fe₂O₃<4%, TiO₂<3%, SiO₂≤37% |

| Forma tal-qamħ | Sferika |

| Koeffiċjent Angolari | ≤1.1 |

| Daqs Partikoli | 45μm -2000μm |

| Refrattarju | ≥1800℃ |

| Densità tal-massa | 1.5-1.6 g/ċm3 |

| Espansjoni Termali (RT-1200 ℃) | 4.5-6.5x10-6/k |

| Kulur | Ramel |

| PH | 6.6-7.3 |

| Kompożizzjoni Mineraloġika | Artab + Kurundun |

| Spiża Aċidu | <1 ml/50g |

| LOI | <0.1% |

Vantaġġ

Kaist ceramic foundry sand is about half as light as zircon and chromite, is about third as light as fused ceramic sand. Compared to these natural sand and other foundry media (the material is able to turn out about twice the number of molds per unit weight). Kaist ceramic foundry sand can deliver mold and core packages with a range of benefits that include higher-strength sand casting packages, with high heat resistance, low thermal expansion, improved final part resolution and a smoother surface finish. It can also be handled very easily, saving labor and transfer power costs. However, the manufacturer recommends paying attention to the amount of binder addition.

Applikazzjoni

L-użu tar-ramel tal-funderija taċ-ċeramika Kaist inaqqas ukoll l-iskart u t-trab, b'valur għoli ta 'reklamazzjoni tal-materjali. Barra minn hekk, ir-ramel tal-funderija taċ-ċeramika Kaist diġà qed jintuża f'aktar minn 100 funderija madwar id-dinja; jistgħu jintużaw fi proċessi tradizzjonali ta’ teħid ta’ moffa biex iwasslu riżultati ta’ kwalità għolja b’firxa ta’ metalli, inklużi azzar (liga baxxa, karbonju u stainless), ħadid (griż, duttili), aluminju, u metalli oħra fejn kontroll strett u l-finitura tal-wiċċ hija mixtieqa.

Partijiet tad-Distribuzzjoni tad-daqs tal-Partiċelli

Id-distribuzzjoni tad-daqs tal-partiċelli tista 'tiġi personalizzata skont il-ħtieġa tiegħek.

|

Malja |

20 | 30 | 40 | 50 | 70 | 100 | 140 | 200 | 270 | Pan | AFS | |

|

μm |

850 | 600 | 425 | 300 | 212 | 150 | 106 | 75 | 53 | Pan | ||

| Kodiċi | 70/140 | ≤5 | 25-35 | 35-50 | 8-15 | ≤5 | ≤1 | 65±4 | ||||

| 140/70 | ≤5 | 15-35 | 35-50 | 20-25 | ≤8 | ≤2 | 70±5 | |||||

| 100/200 | ≤10 | 20-35 | 35-50 | 15-20 | ≤10 | ≤2 | 110±5 | |||||

Kategoriji tal-prodotti