- Afirika

- Ede Albania

- Amharic

- Larubawa

- Ara Armenia

- Azerbaijan

- Basque

- Belarusian

- Ede Bengali

- Ara Bosnia

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Ede Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonia

- Finnish

- Faranse

- Frisia

- Galician

- Georgian

- Jẹmánì

- Giriki

- Gujarati

- Haitian Creole

- hausa

- ara ilu Hawaiani

- Heberu

- Rara

- Miao

- Ede Hungarian

- Icelandic

- igbo

- Ede Indonesian

- Irish

- Itali

- Japanese

- Javanese

- Kannada

- Kasakh

- Khmer

- Ede Rwandan

- Korean

- Kurdish

- Kirgisi

- TB

- Latin

- Latvia

- Lithuania

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Èdè Malta

- Maori

- Marathi

- Mongolian

- Mianma

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scotland Gaelic

- Ede Serbia

- English

- Shona

- Sindhi

- Sinhala

- Slovakia

- Slovenia

- Somali

- Sipeeni

- Ede Sundan

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Tọki

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbekisi

- Vietnamese

- Welsh

- Egba Mi O

- Yiddish

- Yoruba

- Zulu

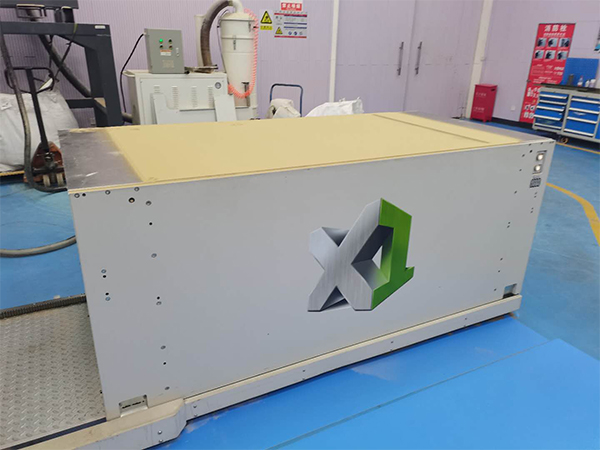

Iyanrin simẹnti seramiki fun iyanrin 3d titẹ sita

Iyanrin seramiki ti Kaist sintered, eyiti o jẹ awọn ọja kanna pẹlu Ceratec's Nagai Cerabeads, jẹ iru iyanrin ipilẹ seramiki Ere kan ti a lo lati ṣẹda awọn molds ati awọn ohun kohun fun simẹnti irin ti o ni iye-giga awọn ọja ni ọkọ ayọkẹlẹ, epo & gaasi, iwakusa ati awọn ile-iṣẹ ikole. Iyẹn pẹlu awọn bulọọki silinda ati awọn falifu hydraulic, bakanna bi awọn ifasoke, awọn ohun mimu ati awọn irinṣẹ. Yanrin atọwọda Kaist jẹ ti awọn kirisita mullite pẹlu didara iduroṣinṣin to gaju. Wọn ti ṣejade nipasẹ sisun awọn granules ti iyipo, kii ṣe nipa fifun wọn.

Bi iyanrin 3D titẹjade ohun elo aise, ni bayi awọn alabaṣiṣẹpọ wa ni ExOne, Voxeljet, KOCEL, ati bẹbẹ lọ julọ.

Ohun-ini Iyanrin seramiki

| Ohun elo Kemikali akọkọ | Al₂O₃≥53%, Fe₂O₃<4%, TiO₂<3%, SiO₂≤37% |

| Apẹrẹ Ọkà | Ti iyipo |

| Angular olùsọdipúpọ | ≤1.1 |

| Apakan Iwon | 45μm -2000μm |

| Refractoriness | ≥1800℃ |

| Olopobobo iwuwo | 1,5-1,6 g / cm3 |

| Imugboroosi Gbona (RT-1200℃) | 4.5-6.5x10-6/k |

| Àwọ̀ | Iyanrin |

| PH | 6.6-7.3 |

| Mineralogical Tiwqn | Asọ + Corundum |

| Iye owo acid | 1 milimita / 50g |

| L.O.I. | 0.1% |

Anfani

Kaist ceramic foundry sand is about half as light as zircon and chromite, is about third as light as fused ceramic sand. Compared to these natural sand and other foundry media (the material is able to turn out about twice the number of molds per unit weight). Kaist ceramic foundry sand can deliver mold and core packages with a range of benefits that include higher-strength sand casting packages, with high heat resistance, low thermal expansion, improved final part resolution and a smoother surface finish. It can also be handled very easily, saving labor and transfer power costs. However, the manufacturer recommends paying attention to the amount of binder addition.

Ohun elo

Lilo iyanrin seramiki seramiki Kaist tun dinku egbin ati eruku, pẹlu iye isọdọtun giga ti awọn ohun elo naa. Ni afikun, Kaist seramiki Foundry iyanrin ti wa ni lilo tẹlẹ ni diẹ sii ju 100 foundries agbaye; wọn le ṣee lo ni awọn ilana ṣiṣe mimu ti aṣa lati fi awọn abajade didara ga pẹlu ọpọlọpọ awọn irin, pẹlu awọn irin (alloy-kekere, carbon, ati alagbara), irin (grẹy, ductile), aluminiomu, ati awọn irin miiran nibiti iṣakoso to muna. ati dada pari ni o fẹ.

Awọn ẹya ara ti patiku iwọn Distribution

Pipin iwọn patiku le jẹ adani gẹgẹbi ibeere rẹ.

|

Apapo |

20 | 30 | 40 | 50 | 70 | 100 | 140 | 200 | 270 | Pan | AFS | |

|

μm |

850 | 600 | 425 | 300 | 212 | 150 | 106 | 75 | 53 | Pan | ||

| Koodu | 70/140 | ≤5 | 25-35 | 35-50 | 8-15 | ≤5 | ≤1 | 65±4 | ||||

| 140/70 | ≤5 | 15-35 | 35-50 | 20-25 | ≤8 | ≤2 | 70±5 | |||||

| 100/200 | ≤10 | 20-35 | 35-50 | 15-20 | ≤10 | ≤2 | 110±5 | |||||

Awọn ẹka ọja