- Afirika

- Chialubaniya

- Chiamharic

- Chiarabu

- Chiameniya

- Chiazerbaijani

- Basque

- Chibelarusi

- Chibengali

- Chibosnia

- Chibugariya

- Chikatalani

- Cebuano

- China

- China (Taiwan)

- Chikosikani

- Chikroatia

- Chicheki

- Chidanishi

- Chidatchi

- Chingerezi

- Chiesperanto

- Chiestonia

- Chifinishi

- Chifalansa

- Chifrisian

- Chigalikiya

- Chijojiya

- Chijeremani

- Chigriki

- Gujarati

- Chikiliyo cha ku Haiti

- hausa

- Hawaii

- Chiheberi

- Ayi

- Miao

- Chihangare

- Chi Icelandic

- igbo

- Chi Indonesian

- ayi

- Chitaliyana

- Chijapani

- Chijavani

- Kanada

- kazakh

- Khmer

- Rwanda

- Chikorea

- Chikurdi

- Kyrgyz

- TB

- Chilatini

- Chilativiya

- Chilithuania

- ChiLuxembourgish

- Chimakedoniya

- Malgashi

- Chimalayi

- Malayalam

- Chimalta

- Chimaori

- Chimarathi

- Chimongoliya

- Myanmar

- Chinepali

- Chinorwe

- Chinorwe

- Occitan

- Pashto

- Chiperisi

- Chipolishi

- Chipwitikizi

- Chipunjabi

- Chiromania

- Chirasha

- Chisamoa

- Scottish Gaelic

- Chisebiya

- Chingerezi

- Chishona

- Sindi

- Sinhala

- Chisilovaki

- Chisiloveniya

- Somalia

- Chisipanishi

- Chisundanese

- Swahili

- Chiswidishi

- Chitagalogi

- Tajiki

- Tamil

- Chitata

- Telugu

- Thai

- Turkey

- Turkmen

- Chiyukireniya

- Chiurdu

- Uighur

- Chiuzbeki

- Vietnamese

- Welsh

- Thandizeni

- Chiyidi

- Chiyoruba

- Chizulu

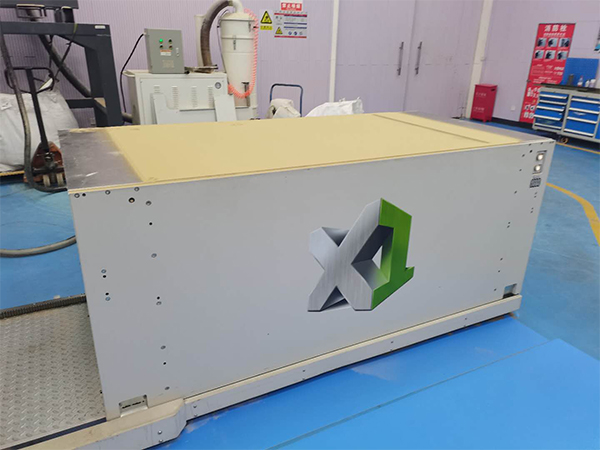

Ceramic kuponyera mchenga kwa mchenga 3d kusindikiza

Kaist sintered Ceramic sand, zomwe ndi zopangidwa zomwezo ndi Ceratec's Nagai Cerabeads, ndi mtundu wa mchenga woyambira wa ceramic womwe umagwiritsidwa ntchito popanga nkhungu ndi ma cores opangira zitsulo zamtengo wapatali m'mafakitale amagalimoto, mafuta & gasi, migodi ndi zomangamanga. Izi zimaphatikizapo midadada ya silinda ndi ma hydraulic valves, komanso mapampu, ma impellers ndi zida. Mchenga wochita kupanga wa Kaist umapangidwa ndi makristalo a mullite okhala ndi mtundu wokhazikika kwambiri. Amapangidwa ndi kuwombera ma granules ozungulira, osati kuwaphwanya.

Monga mchenga 3D kusindikiza zopangira, tsopano anzathu ali ExOne, Voxeljet, KOCEL, etc.

Ceramic Sand Property

| Main Chemical Chigawo | Al₂O₃≥53%, Fe₂O₃<4%, TiO₂<3%, SiO₂≤37% |

| Maonekedwe a Mbewu | Chozungulira |

| Angular Coefficient | ≤1.1 |

| Kukula Kwambiri | 45μm -2000μm |

| Refractoriness | ≥1800 ℃ |

| Kuchulukana Kwambiri | 1.5-1.6 g/cm3 |

| Kukula kwa Thermal (RT-1200 ℃) | 4.5-6.5x10-6/k |

| Mtundu | Mchenga |

| PH | 6.6-7.3 |

| Mineralogical Composition | Soft + Corundum |

| Mtengo wa Acid | 1 ml/50g |

| LOI | <0.1% |

Ubwino

Kaist ceramic foundry sand is about half as light as zircon and chromite, is about third as light as fused ceramic sand. Compared to these natural sand and other foundry media (the material is able to turn out about twice the number of molds per unit weight). Kaist ceramic foundry sand can deliver mold and core packages with a range of benefits that include higher-strength sand casting packages, with high heat resistance, low thermal expansion, improved final part resolution and a smoother surface finish. It can also be handled very easily, saving labor and transfer power costs. However, the manufacturer recommends paying attention to the amount of binder addition.

Kugwiritsa ntchito

Kugwiritsa ntchito mchenga wa Kaist ceramic foundry kumachepetsanso zinyalala ndi fumbi, ndi mtengo wapamwamba wobwezeretsanso zinthuzo. Komanso, Kaist ceramic foundry mchenga kale ntchito pa 100 foundries padziko lonse; Zitha kugwiritsidwa ntchito popanga nkhungu zachikhalidwe kuti zipereke zotsatira zapamwamba kwambiri zokhala ndi zitsulo zingapo, kuphatikiza zitsulo (otsika aloyi, kaboni, ndi zosapanga dzimbiri), chitsulo (imvi, ductile), aluminiyamu, ndi zitsulo zina zomwe zimawongolera mwamphamvu. ndi kumaliza pamwamba kumafunidwa.

Magawo a Particle size Distribution

The tinthu kukula kugawa akhoza makonda malinga ndi lamulo lanu.

|

Mesh |

20 | 30 | 40 | 50 | 70 | 100 | 140 | 200 | 270 | Pansi | AFS | |

|

μm |

850 | 600 | 425 | 300 | 212 | 150 | 106 | 75 | 53 | Pansi | ||

| Kodi | 70/140 | ≤5 | 25-35 | 35-50 | 8-15 | ≤5 | ≤1 | 65 ±4 | ||||

| 140/70 | ≤5 | 15-35 | 35-50 | 20-25 | ≤8 | ≤2 | 70 ±5 | |||||

| 100/200 | ≤10 | 20-35 | 35-50 | 15-20 | ≤10 | ≤2 | 110 ± 5 | |||||

Magulu azinthu