- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

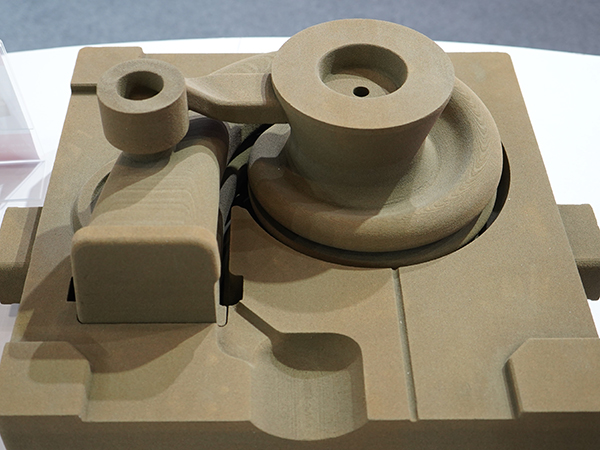

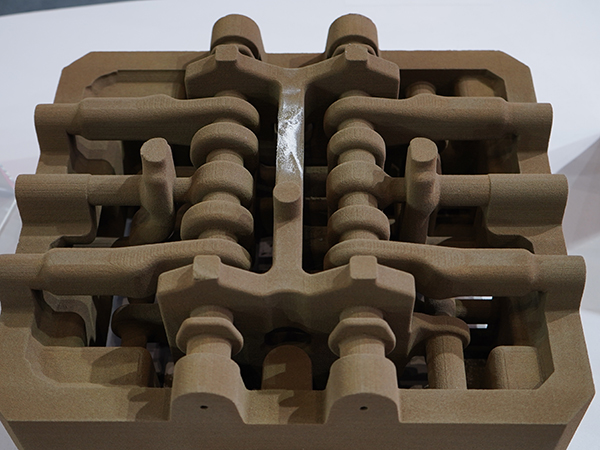

High Refreactoriness Ceramsite Foundry Sand For Steel Casting

| Main Chemical Component | Al₂O₃≥53%, Fe₂O₃<4%, TiO₂<3%, SiO₂≤37% |

| Grain Shape | Spherical |

| Angular Coefficient | ≤1.1 |

| Particle Size | 45μm -2000μm |

| Refractoriness | ≥1800℃ |

| Bulk Density | 1.45-1.6 g/cm3 |

| Thermal Expansion(RT-1200℃) | 4.5-6.5x10-6/k |

| Color | Sand |

| PH | 6.6-7.3 |

| Mineralogical Composition | Mullite + Corundum |

| Acid Cost | <1 ml/50g |

| L.O.I. | <0.1% |

Advantage

● Solid Sphere: The shape of Ceramsite is spherical with smooth surface and less surface area and offering a very good flowability and filling ability. To compare with other sands else, less binder is used at the same mold strength and higher venting ability. It also offers the excellent collapsibility.

● Lower thermal expansion rate: It makes the dimensions of castings better, less crack and defect and higher output.

● Lower breakage rate: Ceramsite has a higher particle strength and a very lower breakage rate at the reclamation. It makes a better reclamations rate to reduce the waste sand and the pollution.

● High refractoriness: The major chemistry is Al2O3 and SiO2, so mostly mullite and corundum phase in the Ceramsite which will make sure the high refractoriness and thermal stability. And PH value appears neutral. It is suitable for all kinds of metal and alloy castings.

Application

Ceramsite Foundry Sand has been engineered specifically for foundries to provide the best performance in various types of castings.

Aluminum, gray and ductile iron, steel, copper, magnesium and other metals can be made using sand and most any binder system including phenolic urethanes, phenolic ester, furan, sodium silicate, bentonite clays, shell resins and alkyd oils.

Parts of Particle size Distribution

The particle size distribution can be customized according your requirement.

|

Mesh |

20 | 30 | 40 | 50 | 70 | 100 | 140 | 200 | 270 | Pan | AFS | |

|

μm |

850 | 600 | 425 | 300 | 212 | 150 | 106 | 75 | 53 | Pan | ||

| Code | 20/40 | 15-40 | 30-55 | 15-35 | ≤5 | 20±5 | ||||||

| 30/50 | ≤1 | 25-35 | 35-50 | 15-25 | ≤10 | ≤1 | 30±5 | |||||

| 40/70 | ≤5 | 20-30 | 40-50 | 15-25 | ≤8 | ≤1 | 43±3 | |||||

| 70/40 | ≤5 | 15-25 | 40-50 | 20-30 | ≤10 | ≤2 | 46±3 | |||||

| 50/100 | ≤5 | 25-35 | 35-50 | 15-25 | ≤6 | ≤1 | 50±3 | |||||

| 100/50 | ≤5 | 15-25 | 35-50 | 25-35 | ≤10 | ≤1 | 55±3 | |||||

| 70/140 | ≤5 | 25-35 | 35-50 | 8-15 | ≤5 | ≤1 | 65±4 | |||||

| 140/70 | ≤5 | 15-35 | 35-50 | 20-25 | ≤8 | ≤2 | 70±5 | |||||

| 100/200 | ≤10 | 20-35 | 35-50 | 15-20 | ≤10 | ≤2 | 110±5 | |||||

Products categories