- umAfrika

- Albanian

- Amharic

- IsiArabhu

- Armenian

- IsiAzerbaijani

- Basque

- IsiBhelarushiyen

- Bengali

- Bosnian

- Bulgarian

- isiKhathalan

- Cebuano

- eTshayina

- iTshayina (eTaiwan)

- isiKhorsikhen

- Croatian

- Czech

- Danish

- IsiDatshi

- IsiNgesi

- isiEsperanto

- Estonian

- Finnish

- IsiFrentshi

- IsiFrisian

- Galician

- Georgian

- IsiJamani

- IsiGrike

- Gujarati

- isiKriyoli saseHayiti

- Hausa

- isiHawayi

- IsiHebhere

- Hayi

- Miao

- Hungarian

- Iceland

- igbo

- Indonesian

- Irish

- IsiTaliyani

- IsiJaphani

- Javanese

- Kannada

- isiKazakh

- Khmer

- isiRwanda

- Korean

- isiKhudish

- isiKyrgyz

- I-TB

- isiLatini

- Latvian

- isiLithuwaniya

- isiLuksembogu

- Mecedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- isiMawori

- Marathi

- isiMongoliya

- Miyanimar

- Nepali

- Norwegian

- Norwegian

- Occitan

- isiPhashto

- Persian

- Polish

- IsiPhuthukezi

- isiPhunjabi

- Romanian

- IsiRashiya

- isiSamoa

- IsiGaelic saseScottish

- isiSebhiya

- IsiNgesi

- IsiShona

- Sindhi

- IsiSinhala

- Slovak

- Slovenian

- isiSomali

- Spanish

- IsiSundanese

- Swahili

- Swedish

- Tagolog

- IsiTajik

- Tamil

- IsiTatar

- Telugu

- IsiThai

- IsiTurkey

- isiTurkmen

- Isi-Ukraine

- IsiUrdu

- Uighur

- IsiUzbek

- IsiVietnamese

- IsiWelsh

- Nceda

- Yiddish

- IsiYoruba

- IsiZulu

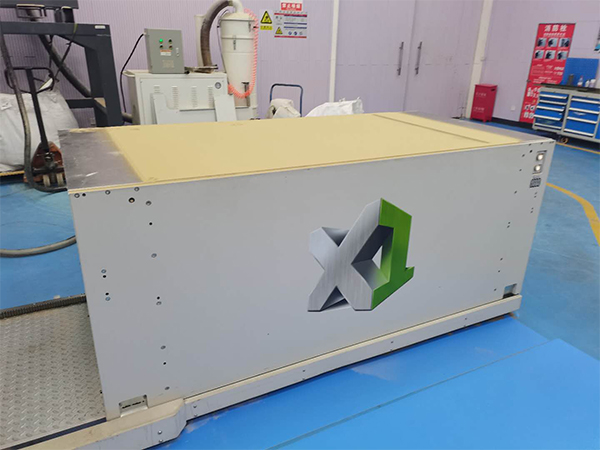

Isanti yokugalela isanti yesanti ye-3d yoshicilelo

I-Kaist sintered Isanti yeCeramic, eyimveliso efanayo kunye neCeratec's Nagai Cerabeads, luhlobo lwesanti yesiseko se-ceramic esetyenziselwa ukwenza imixokelelwane kunye neentsimbi zokuphosa imveliso yexabiso eliphezulu kwimizi-mveliso yeemoto, i-oyile negesi, imigodi neyokwakha. Oko kubandakanya iibhloko ze-cylinder kunye neevalvu ze-hydraulic, kunye neepompo, i-impellers kunye nezixhobo. Isanti eyenziweyo yeKaist yenziwe ngeekristale ze-mullite ezinomgangatho ozinzile kakhulu. Ziveliswa ngokudubula iigranules ezingqukuva, hayi ngokuzityumza.

Njengesanti ye-3D yoshicilelo lwemathiriyeli ekrwada, ngoku amaqabane ethu aneExOne, Voxeljet, KOCEL, njl.

Ipropati yeSanti yeCeramic

| ICandelo leMichiza eliPhambili | Al₂O₃≥53%, Fe₂O₃<4%, TiO₂<3%, SiO₂≤37% |

| Imilo yeenkozo | I-Spherical |

| I-Angular Coefficient | ≤1.1 |

| Ubungakanani obuyinxenye | 45μm -2000μm |

| Ukuchasa | ≥1800℃ |

| Unizi lolwapho kuyiwa khona | 1.5-1.6 g/cm3 |

| Ukwandiswa kweThermal (RT-1200℃) | 4.5-6.5x10-6/k |

| Umbala | Isanti |

| PH | 6.6-7.3 |

| Ukuqulunqwa kweMineralogical | Ithambile + iCorundum |

| Iindleko ze-Acid | <1 ml/50g |

| LOI | <0.1% |

Inzuzo

Kaist ceramic foundry sand is about half as light as zircon and chromite, is about third as light as fused ceramic sand. Compared to these natural sand and other foundry media (the material is able to turn out about twice the number of molds per unit weight). Kaist ceramic foundry sand can deliver mold and core packages with a range of benefits that include higher-strength sand casting packages, with high heat resistance, low thermal expansion, improved final part resolution and a smoother surface finish. It can also be handled very easily, saving labor and transfer power costs. However, the manufacturer recommends paying attention to the amount of binder addition.

Isicelo

Ukusebenzisa Kaist ceramic Foundry isanti kwakhona kunciphisa inkunkuma kunye nothuli, ngexabiso eliphezulu reclamation izinto. Ukongeza, isanti ye-ceramic ye-Kaist sele isetyenziswa kwiindawo ezingaphezu kwe-100 kwihlabathi jikelele; zinokusetyenziswa kwiinkqubo zokwenza i-mold yemveli ukuhambisa iziphumo ezikumgangatho ophezulu kunye noluhlu lwesinyithi, kubandakanywa iintsimbi (i-alloy ephantsi, i-carbon, kunye ne-stainless), isinyithi (igrey, i-ductile), i-aluminium, kunye nezinye iintsimbi apho ulawulo oluluqilima. kunye nokugqitywa komphezulu kuyafunwa.

Iinxalenye zoSabelo lobungakanani beNcam

Ukuhanjiswa kobungakanani besuntswana kunokwenziwa ngokwezifiso ngokwemfuno yakho.

|

Umnatha |

20 | 30 | 40 | 50 | 70 | 100 | 140 | 200 | 270 | Ipani | AFS | |

|

μm |

850 | 600 | 425 | 300 | 212 | 150 | 106 | 75 | 53 | Ipani | ||

| Ikhowudi | 70/140 | ≤5 | 25-35 | 35-50 | 8-15 | ≤5 | ≤1 | 65±4 | ||||

| 140/70 | ≤5 | 15-35 | 35-50 | 20-25 | ≤8 | ≤2 | 70±5 | |||||

| 100/200 | ≤10 | 20-35 | 35-50 | 15-20 | ≤10 | ≤2 | 110±5 | |||||

Iindidi zeemveliso