- Afirka

- Albaniya

- Amharic

- Larabci

- Armenian

- Azerbaijan

- Basque

- Belarushiyanci

- Bengali

- Bosniya

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Yaren mutanen Holland

- Turanci

- Esperanto

- Estoniya

- Finnish

- Faransanci

- Farisa

- Galiciyan

- Jojin

- Jamusanci

- Girkanci

- Gujarati

- Haitian Creole

- hausa

- hawayi

- Ibrananci

- A'a

- Miya

- Harshen Hungary

- Icelandic

- igbo

- Indonesiya

- Irish

- Italiyanci

- Jafananci

- Yawanci

- Kannada

- kazakh

- Khmer

- Ruwanda

- Yaren Koriya

- Kurdish

- Kyrgyzstan

- TB

- Latin

- Latvia

- Lithuaniyanci

- Luxembourgish

- Makidoniya

- Malgashi

- Malay

- Malayalam

- Maltase

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Yaren mutanen Norway

- Yaren mutanen Norway

- Occitan

- Pashto

- Farisa

- Yaren mutanen Poland

- Fotigal

- Punjabi

- Romanian

- Rashanci

- Samoan

- Scottish Gaelic

- Serbian

- Turanci

- Shona

- Sindhi

- Sinhala

- Slovak

- Harshen Sloveniya

- Somaliya

- Mutanen Espanya

- Sundanci

- Harshen Swahili

- Yaren mutanen Sweden

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Baturke

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Taimako

- Yadish

- Yarbawa

- Zulu

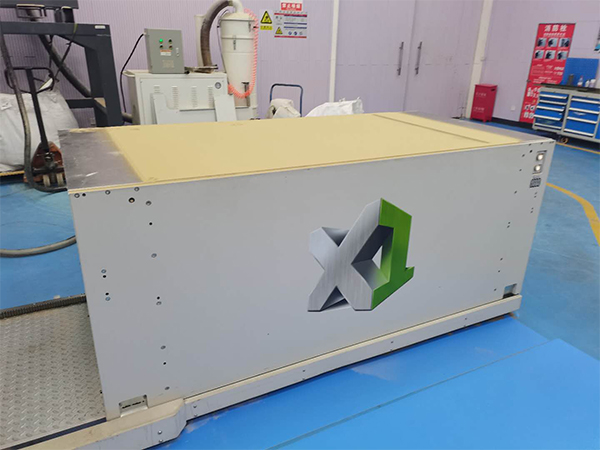

Yashi simintin yumbu don yashi 3d bugu

Kaist sintered Ceramic sand, wanda samfuran iri ɗaya ne tare da Ceratec's Nagai Cerabeads, wani nau'in yashi ne na yumbu mai ƙima da ake amfani da shi don ƙirƙirar gyare-gyare da muryoyi don yin simintin ƙarfe mai ƙima a cikin masana'antar kera, mai & gas, ma'adinai da gine-gine. Wannan ya haɗa da tubalan silinda da bawul ɗin ruwa, da kuma famfo, injina da kayan aiki. Yashi na wucin gadi na Kaist an yi shi da lu'ulu'u na mullite tare da ingantaccen inganci. Ana samar da su ta hanyar harba granules mai siffar zobe, ba ta hanyar murƙushe su ba.

Kamar yadda yashi 3D bugu albarkatun kasa, yanzu abokanmu suna da ExOne, Voxeljet, KOCEL, da dai sauransu.

Abubuwan Yashi na yumbu

| Babban Abun Sinadari | Al₂O₃≥53%, Fe₂O₃<4%, TiO₂<3%, SiO₂≤37% |

| Siffar hatsi | Siffar |

| Angular Coefficient | ≤1.1 |

| Girman Juzu'i | 45 μm - 2000 μm |

| Refractoriness | ≥1800℃ |

| Yawan yawa | 1.5-1.6 g/cm3 |

| Thermal Fadada (RT-1200℃) | 4.5-6.5x10-6/k |

| Launi | Yashi |

| PH | 6.6-7.3 |

| Ma'adinan Ma'adinai | Soft + Corundum |

| Farashin Acid | 1 ml/50g |

| LOI | 0.1% |

Amfani

Kaist ceramic foundry sand is about half as light as zircon and chromite, is about third as light as fused ceramic sand. Compared to these natural sand and other foundry media (the material is able to turn out about twice the number of molds per unit weight). Kaist ceramic foundry sand can deliver mold and core packages with a range of benefits that include higher-strength sand casting packages, with high heat resistance, low thermal expansion, improved final part resolution and a smoother surface finish. It can also be handled very easily, saving labor and transfer power costs. However, the manufacturer recommends paying attention to the amount of binder addition.

Aikace-aikace

Yin amfani da yashi mai tushe na Kaist yumbu kuma yana rage sharar gida da ƙura, tare da ƙima mai girma na kayan. Bugu da kari, Kaist yumbu foundry yashi an riga an yi amfani da fiye da 100 foundries a dukan duniya; ana iya amfani da su a cikin tsarin yin gyare-gyare na gargajiya don sadar da sakamako mai inganci tare da kewayon karafa, gami da karafa (ƙananan gami, carbon, da bakin ƙarfe), ƙarfe (launin toka, ductile), aluminum, da sauran ƙarfe inda m iko. kuma ana son gamawa.

Sassan Rarraba Girman Barbashi

Za'a iya daidaita girman girman barbashi bisa ga buƙatun ku.

|

raga |

20 | 30 | 40 | 50 | 70 | 100 | 140 | 200 | 270 | Pan | Farashin AFS | |

|

μm |

850 | 600 | 425 | 300 | 212 | 150 | 106 | 75 | 53 | Pan | ||

| Lambar | 70/140 | ≤5 | 25-35 | 35-50 | 8-15 | ≤5 | ≤1 | 65± 4 | ||||

| 140/70 | ≤5 | 15-35 | 35-50 | 20-25 | ≤8 | ≤2 | 70± 5 | |||||

| 100/200 | ≤10 | 20-35 | 35-50 | 15-20 | ≤10 | ≤2 | 110± 5 | |||||

Rukunin samfuran