- African

- ChiAlbanian

- ChiAmharic

- ChiArabic

- ChiArmenian

- Azerbaijani

- ChiBasque

- Chiberaruzi

- ChiBengali

- ChiBosnian

- ChiBulgarian

- Katarani

- Cebuano

- China

- China (Taiwan)

- Kosikeni

- ChiCroatian

- ChiCzech

- ChiDanish

- ChiDutch

- Chirungu

- Esiperando

- ChiEstonian

- ChiFinish

- ChiFrench

- Frisian

- ChiGalician

- ChiGeorgian

- ChiJerimani

- ChiGiriki

- ChiGujarati

- Kiriyoro yeHaiti

- ChiHausa

- Chihawayi

- ChiHebhuru

- kwete

- Miao

- ChiHungarian

- ChiIcelandic

- igbo

- ChiIndonesian

- ChiIrish

- ChiItalian

- ChiJapanese

- ChiJavanese

- ChiKannada

- Kazaki

- Khmer

- Rwandan

- ChiKorean

- ChiKedhi

- Kiyagizi

- TB

- Ratini

- ChiLatvian

- Ritunia

- Rukusembogi

- ChiMacedonian

- Malgashi

- ChiMalay

- ChiMalayalam

- ChiMaltese

- Maori

- ChiMarati

- ChiMongoria

- Mayanima

- ChiNepali

- ChiNorwegian

- ChiNorwegian

- Occitan

- Pashito

- ChiPersian

- ChiPolish

- ChiPutukezi

- Punjabi

- ChiRomanian

- ChiRussian

- Samoan

- ChiGaelic cheScottish

- ChiSebhiya

- Chirungu

- Shona

- ChiSindhi

- Sinhala

- ChiSlovak

- ChiSlovanian

- Somari

- ChiSpanish

- Sundanese

- ChiSwahili

- ChiSwedish

- ChiTagalog

- Tajik

- ChiTamil

- Tatar

- ChiTelugu

- ChiThai

- Turkish

- ChiTeki

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Help

- Yiddish

- Yoruba

- Zulu

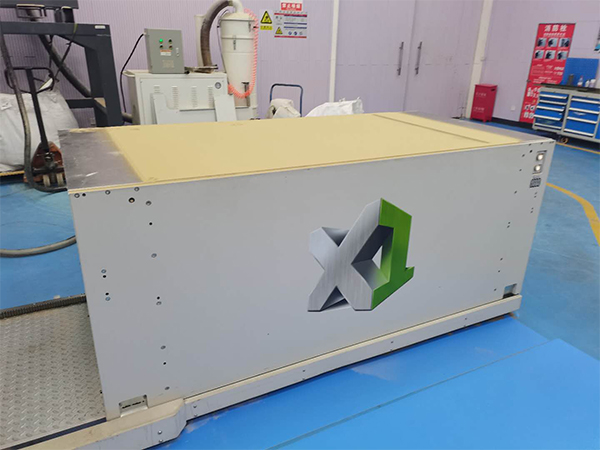

Ceramic kukanda jecha rejecha 3d kudhinda

Kaist sintered Ceramic sand, izvo zvakafanana zvigadzirwa neCeratec's Nagai Cerabeads, imhando ye premium ceramic foundry jecha rinoshandiswa kugadzira mold uye macores ekukanda simbi zvigadzirwa zvemhando yepamusoro mumotokari, oiri & gasi, migodhi uye maindasitiri ekuvaka. Izvo zvinosanganisira cylinder blocks uye hydraulic valves, pamwe nemapombi, impellers uye zvishandiso. Kaist artificial jecha anogadzirwa nema mullite makristasi ane akanyanya kugadzikana mhando. Iwo anogadzirwa nekupfura spherical granules, kwete nekuapwanya.

Sejecha 3D inodhinda mbishi zvinhu, ikozvino vatinoshanda navo vane ExOne, Voxeljet, KOCEL, nezvimwe.

Ceramic Sand Property

| Main Chemical Component | Al₂O₃≥53%, Fe₂O₃<4%, TiO₂<3%, SiO₂≤37% |

| Zviyo Chimiro | Spherical |

| Angular Coefficient | ≤1.1 |

| Chikamu Saizi | 45μm -2000μm |

| Refractoriness | ≥1800℃ |

| Bulk Density | 1.5-1.6 g/cm3 |

| Kuwedzera Kwekupisa (RT-1200℃) | 4.5-6.5x10-6/k |

| Color | Jecha |

| PH | 6.6-7.3 |

| Mineralogical Composition | Yakapfava + Corundum |

| Acid Cost | <1 ml/50g |

| LOI | <0.1% |

Advantage

Kaist ceramic foundry sand is about half as light as zircon and chromite, is about third as light as fused ceramic sand. Compared to these natural sand and other foundry media (the material is able to turn out about twice the number of molds per unit weight). Kaist ceramic foundry sand can deliver mold and core packages with a range of benefits that include higher-strength sand casting packages, with high heat resistance, low thermal expansion, improved final part resolution and a smoother surface finish. It can also be handled very easily, saving labor and transfer power costs. However, the manufacturer recommends paying attention to the amount of binder addition.

Application

Kushandisa Kaist ceramic foundry jecha zvakare kunoderedza marara uye guruva, ine yakakwirira reclamation kukosha kwezvinhu. Mukuwedzera, Kaist zvedongo foundry jecha vari kutoshandiswa panguva dzinopfuura 100 foundries munyika yose; zvinogona kushandiswa mumaitiro echinyakare ekugadzira mold kuendesa mhedzisiro yemhando yepamusoro nemhando yesimbi, kusanganisira simbi (yakaderera-alloy, kabhoni, uye isina tsvina), simbi (grey, ductile), aruminiyamu, uye dzimwe simbi uko kusimba kunodzora. uye kupera kwepamusoro kunodiwa.

Zvikamu zveParticle size Distribution

Iyo particle size yekugovera inogona kugadzirwa zvinoenderana nezvaunoda.

|

Mesh |

20 | 30 | 40 | 50 | 70 | 100 | 140 | 200 | 270 | Pan | AFS | |

|

μm |

850 | 600 | 425 | 300 | 212 | 150 | 106 | 75 | 53 | Pan | ||

| Code | 70/140 | ≤5 | 25-35 | 35-50 | 8-15 | ≤5 | ≤1 | 65±4 | ||||

| 140/70 | ≤5 | 15-35 | 35-50 | 20-25 | ≤8 | ≤2 | 70±5 | |||||

| 100/200 | ≤10 | 20-35 | 35-50 | 15-20 | ≤10 | ≤2 | 110±5 | |||||

Zvigadzirwa zvikamu