- Awherika

- Albanian

- Amharic

- Arapi

- Arameina

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnia

- Bulgarian

- Katarana

- Cebuano

- Haina

- Haina (Taiwan)

- Korihika

- Koroatiana

- Czech

- Teniana

- Tatimana

- Ingarihi

- Esperanto

- Estonian

- Finnish

- Wīwī

- Frisian

- Kariri

- Georgian

- Tiamana

- Kariki

- Gujarati

- Haiti Creole

- hausa

- hawaii

- Hiperu

- Kao

- Miao

- Hungarian

- Tiorangi

- igbo

- Initonia

- Irish

- Itari

- Hapanihi

- Hawaana

- Kannada

- Kazakh

- Khmer

- Rwandan

- Koreana

- Kurdish

- Kyrgyz

- TB

- Latina

- Latvian

- Lithuanian

- Luxembourgish

- Makeronia

- Malgashi

- Malay

- Malayalam

- Marite

- Maori

- Mareti

- Mongolian

- Myanmar

- Nepali

- Norewai

- Norewai

- Occitan

- Pashto

- Pahia

- Porohia

- Potiti

- Punjabi

- Romanian

- Ruhia

- Hamoa

- Scottish Gaelic

- Serbian

- Ingarihi

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Paniora

- Hatana

- Swahili

- Huitene

- Tagalog

- Tajik

- Tamil

- Tatara

- Telugu

- Thai

- Turkish

- Turkmen

- Iukereiniana

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Awhina

- Yiddish

- Yoruba

- Zulu

Te kirikiri whakarewa mo te kirikiri 3d

Ko te kirikiri Ceramic sintered Kaist, he rite tonu nga hua me nga Ceratec's Nagai Cerabeads, he momo kirikiri hanga uku utu nui hei hanga i nga pokepokea me nga matua mo te whakarewa i nga hua utu nui i roto i nga umanga miihini, hinu me te hau, maina me nga umanga hanga. Kei roto ko nga poraka porotakaro me nga reera waipēhi, tae atu ki nga papua, impeller me nga taputapu. Ko te kirikiri kirikiri kaist he mea hanga mai i nga tioata mullite me te kounga tino pumau. Ka mahia ma te pupuhi i nga kirikiri porohita, kaua ma te kuru.

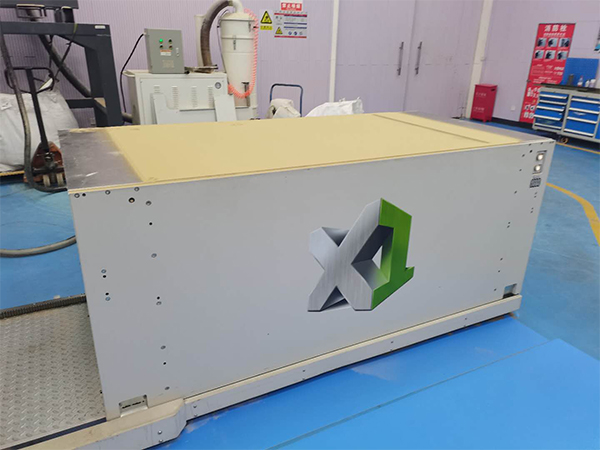

I te mea ko te kirikiri 3D nga rauemi mata, inaianei kei a maatau hoa a ExOne, Voxeljet, KOCEL, me era atu.

Taonga kirikiri uku

| Wae Matū Matua | Al₂O₃≥53%, Fe₂O₃<4%, TiO₂<3%, SiO₂≤37% |

| Hanga witi | Porowhita |

| Kohanga Koki | ≤1.1 |

| Rahi Wahi | 45μm -2000μm |

| Rereira | ≥1800 ℃ |

| Kiato Nui | 1.5-1.6 g/cm3 |

| Roha Ngaaahu(RT-1200℃) | 4.5-6.5x10-6/k |

| Tae | kirikiri |

| PH | 6.6-7.3 |

| Waihanga Kohuke | Ngohe + Corundum |

| Utu Waikawa | <1 ml/50g |

| LOI | <0.1% |

Painga

Kaist ceramic foundry sand is about half as light as zircon and chromite, is about third as light as fused ceramic sand. Compared to these natural sand and other foundry media (the material is able to turn out about twice the number of molds per unit weight). Kaist ceramic foundry sand can deliver mold and core packages with a range of benefits that include higher-strength sand casting packages, with high heat resistance, low thermal expansion, improved final part resolution and a smoother surface finish. It can also be handled very easily, saving labor and transfer power costs. However, the manufacturer recommends paying attention to the amount of binder addition.

Taupānga

Ma te whakamahi i te kirikiri kirikiri kirikiri Kaist ka whakaiti i te para me te puehu, he nui te uara whakaora o nga rawa. I tua atu, kua whakamahia kētia te kirikiri kirikiri kirikiri Kaist i neke atu i te 100 nga whare hangahanga puta noa i te ao; ka taea te whakamahi i roto i nga tikanga hanga pokepokea ai ki te whakaputa i nga hua o te kounga teitei me te maha o nga konganuku, tae atu ki nga tira (he iti-te konupora, te waro, me te kowiri), te rino (hina, ductile), konumohe, me etahi atu konganuku ka kaha te whakahaere. me te whakaoti mata e hiahiatia ana.

Nga Waahanga o te Rahi Matūriki Tohatoha

Ko te tohatoha rahi matūriki ka taea te whakarite kia rite ki to hiahia.

|

Matau |

20 | 30 | 40 | 50 | 70 | 100 | 140 | 200 | 270 | Pan | AFS | |

|

μm |

850 | 600 | 425 | 300 | 212 | 150 | 106 | 75 | 53 | Pan | ||

| Waehere | 70/140 | ≤5 | 25-35 | 35-50 | 8-15 | ≤5 | ≤1 | 65±4 | ||||

| 140/70 | ≤5 | 15-35 | 35-50 | 20-25 | ≤8 | ≤2 | 70±5 | |||||

| 100/200 | ≤10 | 20-35 | 35-50 | 15-20 | ≤10 | ≤2 | 110±5 | |||||

Nga waahanga hua