- Aferika

- Alapania

- Amharic

- Alapi

- Armenian

- Azerbaijani

- Basque

- Pelalusiana

- Bengali

- Bosnian

- Bulgarian

- Katalana

- Sepuano

- Saina

- Saina (Taiwan)

- Kosikana

- Croatian

- Czech

- Danish

- Siamani

- Igilisi

- Eseperano

- Estonian

- Finnish

- Falani

- Frisian

- Galician

- Georgian

- Siamani

- Greek

- Gujarati

- Haiti Kereole

- Hausa

- Havaii

- Eperu

- Leai

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- Aialani

- Italia

- Iapani

- Javanese

- Kannada

- Kasaka

- Khmer

- Rwanda

- Kolea

- Kutisa

- Kirikisi

- TB

- Latina

- Latvian

- Lituaniana

- Lusemipoukisi

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maoli

- Marathi

- Mokoliana

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pasato

- Persian

- Polish

- Portuguese

- Punitapi

- Lomani

- Lusia

- Samoa

- Sikotilani Gaelic

- Serbian

- Igilisi

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sipaniolo

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Fa'a Thai

- Turkish

- tamaloloa Take

- Ukaraina

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Uelese

- Fesoasoani

- Yiddish

- Yoruba

- Zulu

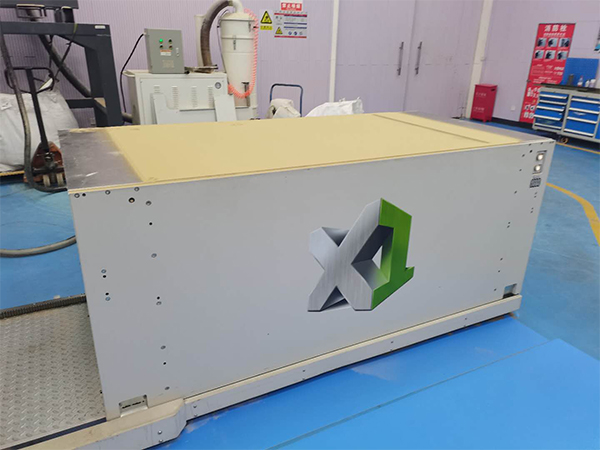

oneone lafo sima mo oneone 3d lolomi

Kaist sintered Ceramic oneone, o oloa tutusa ma Ceratec's Nagai Cerabeads, o se ituaiga o oneone fau sima faʻaaogaina e fai ai limu ma fatu mo le faʻaaogaina o uʻamea maualuga-taua oloa i fale taʻavale, suauʻu & kesi, eli ma fale faufale. E aofia ai poloka pa'u ma alavai hydraulic, fa'apea fo'i pamu, impellers ma meafaigaluega. O le oneone fa'akomepiuta Kaist e faia i tioata mullite e matua'i mautu lelei. E gaosia e ala i le sasaina o granules spherical, ae le o le tuʻimomomoina.

E pei o le oneone 3D lolomi mea mata, o lea ua i ai a tatou paaga ExOne, Voxeljet, KOCEL, ma isi.

Meatotino oneone Keramik

| Vaega Vailaau Autu | Al₂O₃≥53%, Fe₂O₃<4%, TiO₂<3%, SiO₂≤37% |

| Fuga o Saito | Spherical |

| Coefficient Angular | ≤1.1 |

| Lapata'iga | 45μm -2000μm |

| Fa'aleaogaina | ≥1800℃ |

| To'atele Tele | 1.5-1.6 g/cm3 |

| Fa'alauteleina o le vevela(RT-1200℃) | 4.5-6.5x10-6/k |

| Lanu | oneone |

| PH | 6.6-7.3 |

| Fa'asologa o minerale | Malu + Corundum |

| Tau ole acid | <1 ml/50g |

| LOI | <0.1% |

Fa'amanuiaga

Kaist ceramic foundry sand is about half as light as zircon and chromite, is about third as light as fused ceramic sand. Compared to these natural sand and other foundry media (the material is able to turn out about twice the number of molds per unit weight). Kaist ceramic foundry sand can deliver mold and core packages with a range of benefits that include higher-strength sand casting packages, with high heat resistance, low thermal expansion, improved final part resolution and a smoother surface finish. It can also be handled very easily, saving labor and transfer power costs. However, the manufacturer recommends paying attention to the amount of binder addition.

Fa'aaogāga

O le fa'aogaina o le oneone fa'ameamea o le Kaist e fa'aitiitia ai lapisi ma pefu, fa'atasi ai ma le maualuga o le toe fa'aleleia o mea. E le gata i lea, o le Kaist ceramic foundry sand ua uma ona faʻaaogaina i le sili atu i le 100 foundries i le lalolagi atoa; e mafai ona fa'aaogaina i faiga fa'asolo fa'aleaganu'u e tu'uina atu ai i'uga sili ona lelei ma le tele o u'amea, e aofia ai u'amea (maualalo-alloy, carbon, ma stainless), u'amea (efuefu, ductile), alumini, ma isi u'amea o lo'o pulea lelei. ma e mana'omia le fa'auma o luga.

Vaega o Fa'asoa Lapopo'a

E mafai ona fa'avasegaina le fa'asoaina o le lapopoa e tusa ai ma lou mana'oga.

|

Mesh |

20 | 30 | 40 | 50 | 70 | 100 | 140 | 200 | 270 | Pan | AFS | |

|

μm |

850 | 600 | 425 | 300 | 212 | 150 | 106 | 75 | 53 | Pan | ||

| Code | 70/140 | ≤5 | 25-35 | 35-50 | 8-15 | ≤5 | ≤1 | 65±4 | ||||

| 140/70 | ≤5 | 15-35 | 35-50 | 20-25 | ≤8 | ≤2 | 70±5 | |||||

| 100/200 | ≤10 | 20-35 | 35-50 | 15-20 | ≤10 | ≤2 | 110±5 | |||||

Vaega o oloa