- Afrika

- basa Albania

- Amharik

- Arab

- Arménia

- Basa Azerbaijan

- Basque

- Bélarus

- Benggala

- Bosnia

- basa Bulgaria

- Katalan

- Cebuano

- Cina

- Cina (Taiwan)

- Korsika

- Kroasia

- Ceko

- Denmark

- Walanda

- Inggris

- Ésperanto

- Éstonia

- Finlandia

- Perancis

- Frisian

- Galician

- Georgian

- Jerman

- Yunani

- Gujarati

- Kréol Haiti

- hausa

- Hawai

- Ibrani

- Heueuh

- Miao

- Hungaria

- Islandia

- igbo

- basa Indonésia

- Basa Irlandia

- Italia

- Basa Jepang

- basa Jawa

- Kannada

- kazakh

- Khmer

- Rwandan

- Koréa

- Kurdi

- Kirgiz

- TB

- Latin

- Lativia

- Lituania

- Luksemburg

- Makedonia

- Malgashi

- Malayu

- Malayalam

- Malta

- Maori

- Marathi

- Mongol

- Myanmar

- Nepali

- Norwegia

- Norwegia

- Occitan

- Pashto

- Pérsia

- Polandia

- Portugis

- Punjabi

- Romania

- Rusia

- Samoan

- Gaelik Skotlandia

- Sérbia

- Inggris

- Shona

- Sindhi

- Sinhala

- Slowakia

- Slovénia

- Somali

- Spanyol

- Sundanese

- basa Swahili

- Swédia

- Tagalog

- Tajik

- Tamil

- Tatar Sunda

- Telugu

- Thai

- Turki

- Turkmén

- Ukrania

- Basa Urdu

- Uighur

- Uzbek

- Vietnam

- Welsh

- Tulung

- Yiddish

- Yoruba

- Zulu

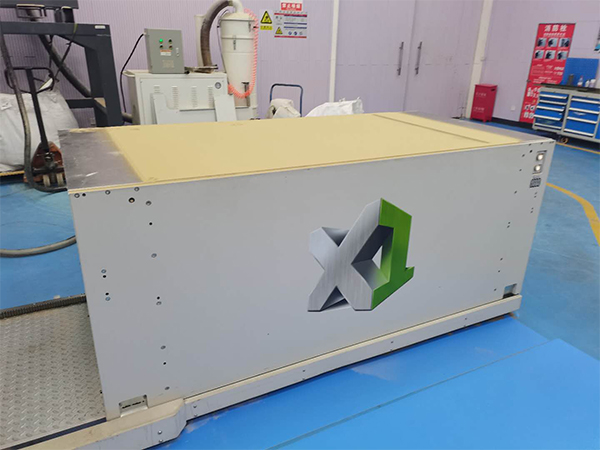

Keusik tuang keramik pikeun percetakan 3d keusik

Keusik Keramik anu disinter Kaist, anu mangrupikeun produk anu sami sareng Ceratec Nagai Cerabeads, mangrupikeun jinis pasir pengecoran keramik premium anu dianggo pikeun nyiptakeun kapang sareng inti pikeun tuang logam produk bernilai tinggi dina industri otomotif, minyak & gas, pertambangan sareng konstruksi. Éta kalebet blok silinder sareng klep hidrolik, ogé pompa, impeller sareng alat. Keusik jieunan Kaist dijieun tina kristal mullite kalawan kualitas pisan stabil. Éta dihasilkeun ku némbak granul spherical, sanés ku ngancurkeunana.

Salaku bahan baku percetakan 3D keusik, ayeuna mitra kami boga ExOne, Voxeljet, KOCEL, jsb paling

Keramik Pasir Harta

| Komponén Kimia Utama | Al₂O₃≥53%, Fe₂O₃<4%, TiO₂<3%, SiO₂≤37% |

| Wangun sisikian | Bulat |

| Koéfisién sudut | ≤1.1 |

| Ukuran Partikel | 45μm -2000μm |

| Refractoriness | ≥1800 ℃ |

| Kapadetan Bulk | 1,5-1,6 g / cm3 |

| Ékspansi termal (RT-1200 ℃) | 4.5-6.5x10-6/k |

| Warna | Keusik |

| PH | 6.6-7.3 |

| Komposisi Mineralogi | Lemes + Corundum |

| Biaya Asam | <1 ml/50g |

| LOI | <0,1% |

Kauntungan

Kaist ceramic foundry sand is about half as light as zircon and chromite, is about third as light as fused ceramic sand. Compared to these natural sand and other foundry media (the material is able to turn out about twice the number of molds per unit weight). Kaist ceramic foundry sand can deliver mold and core packages with a range of benefits that include higher-strength sand casting packages, with high heat resistance, low thermal expansion, improved final part resolution and a smoother surface finish. It can also be handled very easily, saving labor and transfer power costs. However, the manufacturer recommends paying attention to the amount of binder addition.

Aplikasi

Ngagunakeun keusik foundry keramik Kaist ogé ngurangan runtah jeung lebu, kalawan nilai reclamation tinggi bahan. Sajaba ti éta, Kaist keramik foundry keusik geus dipaké dina leuwih ti 100 foundries sakuliah dunya; aranjeunna bisa dipaké dina prosés kapang-nyieun tradisional pikeun nganteurkeun hasil kualitas luhur kalawan sauntuyan logam, kaasup steels (low-alloy, karbon, sarta stainless steel), beusi (abu, ductile), aluminium, sarta logam lianna dimana kontrol ketat. jeung finish permukaan anu dipikahoyong.

Bagian tina Distribusi ukuran partikel

Sebaran ukuran partikel bisa ngaropéa nurutkeun sarat Anjeun.

|

bolong |

20 | 30 | 40 | 50 | 70 | 100 | 140 | 200 | 270 | Pan | AFS | |

|

μm |

850 | 600 | 425 | 300 | 212 | 150 | 106 | 75 | 53 | Pan | ||

| Kodeu | 70/140 | ≤5 | 25-35 | 35-50 | 8-15 | ≤5 | ≤1 | 65±4 | ||||

| 140/70 | ≤5 | 15-35 | 35-50 | 20-25 | ≤8 | ≤2 | 70±5 | |||||

| 100/200 | ≤10 | 20-35 | 35-50 | 15-20 | ≤10 | ≤2 | 110±5 | |||||

Kategori produk