- Umunyafurika

- Ikinyalubaniya

- Amharic

- Icyarabu

- Ikinyarumeniya

- Azaribayijan

- Basque

- Biyelorusiya

- Ikibengali

- Bosiniya

- Buligariya

- Igikatalani

- Cebuano

- Ubushinwa

- Ubushinwa (Tayiwani)

- Corsican

- Igikorowasiya

- Ceki

- Danemark

- Ikidage

- Icyongereza

- Esperanto

- Esitoniya

- Igifinilande

- Igifaransa

- Igifaransa

- Abagalatiya

- Jeworujiya

- Ikidage

- Ikigereki

- Gujarati

- Igikerewole

- hausa

- hawaiian

- Igiheburayo

- Oya

- Miao

- Hongiriya

- Isilande

- igbo

- Indoneziya

- irish

- Umutaliyani

- Ikiyapani

- Javanese

- Kannada

- kazakh

- Khmer

- Rwanda

- Igikoreya

- Kurdish

- Kirigizisitani

- Igituntu

- Ikilatini

- Ikilatini

- Lituwaniya

- Luxembourgish

- Abanyamakedoniya

- Malgashi

- Malayika

- Malayalam

- Maltese

- Maori

- Marathi

- Mongoliya

- Miyanimari

- Nepali

- Noruveje

- Noruveje

- Occitan

- Pashto

- Persian

- Igipolonye

- Igiporutugali

- Punjabi

- Ikinyarumaniya

- Ikirusiya

- Samoan

- Abanya-Gaelic

- Igiseribiya

- Icyongereza

- Shona

- Sindhi

- Sinhala

- Igisilovaki

- Igisiloveniya

- Somaliya

- Icyesipanyoli

- Sundanese

- Igiswahiri

- Igisuwede

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Tayilande

- Turukiya

- Abanyaturukiya

- Ukraine

- Urdu

- Uighur

- Uzbek

- Abanya Vietnam

- Welsh

- Ubufasha

- Yiddish

- Yoruba

- Zulu

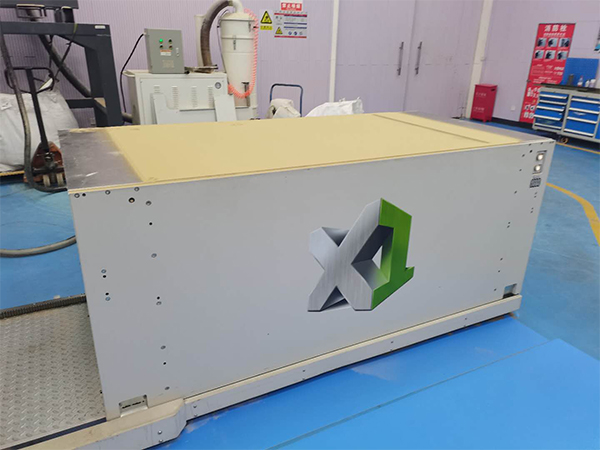

Ceramic guta umucanga kumucanga 3d

Kaist yacumuye umucanga wa Ceramic, nibicuruzwa bimwe na Nagai Cerabeads ya Ceratec, ni ubwoko bwumucanga wa ceramic premium ceramic rukoreshwa mugukora ibishushanyo mbonera hamwe nibyuma byo guta ibyuma bifite agaciro kanini mumodoka, peteroli, gaze, ubucukuzi bwamabuye y'agaciro nubwubatsi. Ibyo bikubiyemo guhagarika silinderi hamwe na hydraulic valve, hamwe na pompe, imashini n'ibikoresho. Kaist artificiel yakozwe muri kristu ya mullite ifite ubuziranenge buhamye. Byakozwe no kurasa granules, ntabwo ari ukujanjagura.

Nkumucanga 3D icapa ibikoresho bibisi, ubu abafatanyabikorwa bacu bafite ExOne, Voxeljet, KOCEL, nibindi byinshi

Umutungo wumucanga Ceramic

| Ibikoresho nyamukuru byimiti | Al₂O₃≥53%, Fe₂O₃ < 4%, TiO₂ < 3%, SiO₂≤37% |

| Imiterere y'ibinyampeke | Umubumbe |

| Coefficient ya Angular | ≤1.1 |

| Ingano yihariye | 45μm -2000μm |

| Kwanga | 001800 ℃ |

| Ubucucike bwinshi | 1.5-1,6 g / cm3 |

| Kwagura Ubushyuhe (RT-1200 ℃) | 4.5-6.5x10-6 / k |

| Ibara | Umusenyi |

| PH | 6.6-7.3 |

| Ibigize amabuye y'agaciro | Byoroheje + Corundum |

| Igiciro cya Acide | Ml 1 ml / 50g |

| LOI | < 0.1% |

Ibyiza

Kaist ceramic foundry sand is about half as light as zircon and chromite, is about third as light as fused ceramic sand. Compared to these natural sand and other foundry media (the material is able to turn out about twice the number of molds per unit weight). Kaist ceramic foundry sand can deliver mold and core packages with a range of benefits that include higher-strength sand casting packages, with high heat resistance, low thermal expansion, improved final part resolution and a smoother surface finish. It can also be handled very easily, saving labor and transfer power costs. However, the manufacturer recommends paying attention to the amount of binder addition.

Gusaba

Gukoresha Kaist ceramic fondasiyo yumucanga nabyo bigabanya imyanda n ivumbi, hamwe nigiciro kinini cyo gutangaza ibikoresho. Mubyongeyeho, umucanga wa Kaist ceramic usanzwe usanzwe ukoreshwa mumishinga irenga 100 kwisi yose; zirashobora gukoreshwa muburyo bwa gakondo bwo gukora ibishushanyo kugirango bitange ibisubizo byiza cyane hamwe nibyuma bitandukanye, harimo ibyuma (amavuta make, karubone, na stainless), ibyuma (imvi, imyanda), aluminium, nibindi byuma aho bigenzurwa cyane kandi hejuru birarangiye.

Ibice bya Particle ingano Ikwirakwizwa

Ingano yubunini bushobora kugabanywa ukurikije ibyo usabwa.

|

Mesh |

20 | 30 | 40 | 50 | 70 | 100 | 140 | 200 | 270 | Isafuriya | AFS | |

|

μm |

850 | 600 | 425 | 300 | 212 | 150 | 106 | 75 | 53 | Isafuriya | ||

| Kode | 70/140 | ≤5 | 25-35 | 35-50 | 8-15 | ≤5 | ≤1 | 65 ± 4 | ||||

| 140/70 | ≤5 | 15-35 | 35-50 | 20-25 | ≤8 | ≤2 | 70 ± 5 | |||||

| 100/200 | ≤10 | 20-35 | 35-50 | 15-20 | ≤10 | ≤2 | 110 ± 5 | |||||

Ibyiciro byibicuruzwa