- umAfrika

- Albanian

- Amharic

- IsiArabhu

- Armenian

- IsiAzerbaijani

- Basque

- IsiBhelarushiyen

- Bengali

- Bosnian

- Bulgarian

- isiKhathalan

- Cebuano

- eTshayina

- iTshayina (eTaiwan)

- isiKhorsikhen

- Croatian

- Czech

- Danish

- IsiDatshi

- IsiNgesi

- isiEsperanto

- Estonian

- Finnish

- IsiFrentshi

- IsiFrisian

- Galician

- Georgian

- IsiJamani

- IsiGrike

- Gujarati

- isiKriyoli saseHayiti

- Hausa

- isiHawayi

- IsiHebhere

- Hayi

- Miao

- Hungarian

- Iceland

- igbo

- Indonesian

- Irish

- IsiTaliyani

- IsiJaphani

- Javanese

- Kannada

- isiKazakh

- Khmer

- isiRwanda

- Korean

- isiKhudish

- isiKyrgyz

- I-TB

- isiLatini

- Latvian

- isiLithuwaniya

- isiLuksembogu

- Mecedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- isiMawori

- Marathi

- isiMongoliya

- Miyanimar

- Nepali

- Norwegian

- Norwegian

- Occitan

- isiPhashto

- Persian

- Polish

- IsiPhuthukezi

- isiPhunjabi

- Romanian

- IsiRashiya

- isiSamoa

- IsiGaelic saseScottish

- isiSebhiya

- IsiNgesi

- IsiShona

- Sindhi

- IsiSinhala

- Slovak

- Slovenian

- isiSomali

- Spanish

- IsiSundanese

- Swahili

- Swedish

- Tagolog

- IsiTajik

- Tamil

- IsiTatar

- Telugu

- IsiThai

- IsiTurkey

- isiTurkmen

- Isi-Ukraine

- IsiUrdu

- Uighur

- IsiUzbek

- IsiVietnamese

- IsiWelsh

- Nceda

- Yiddish

- IsiYoruba

- IsiZulu

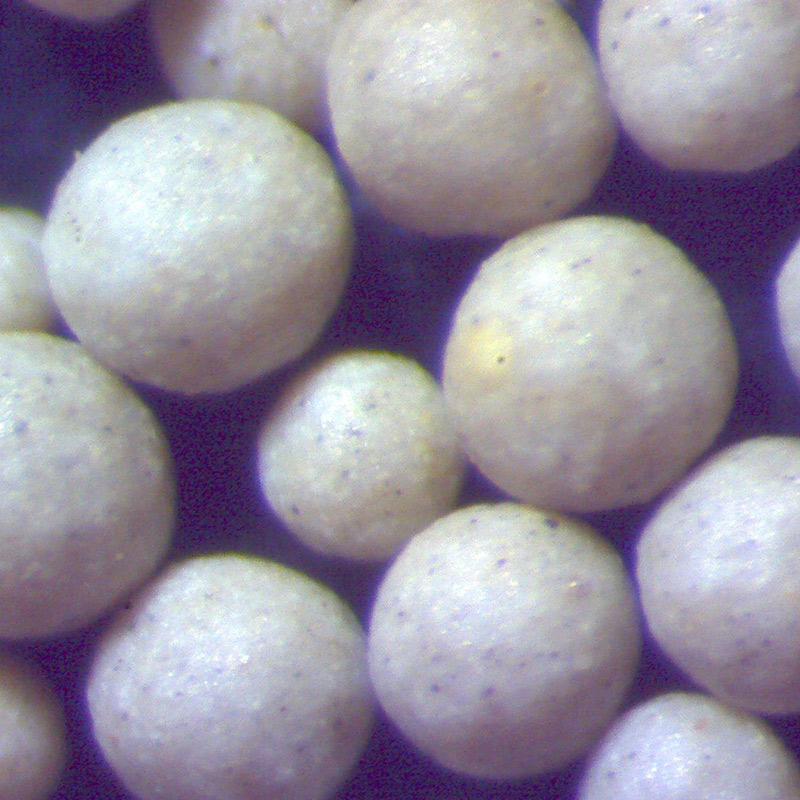

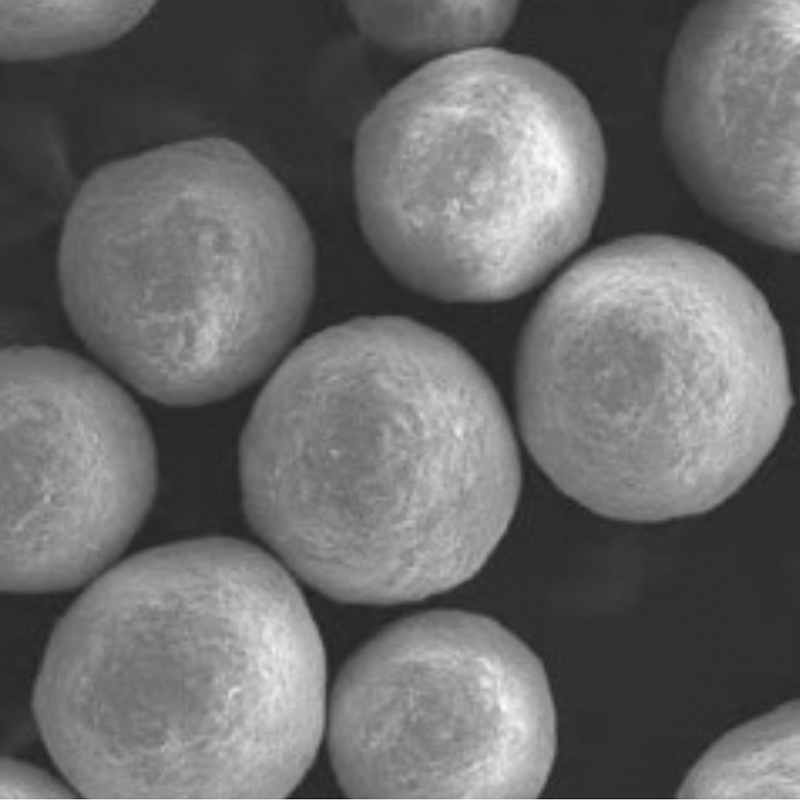

Isanti yeCeramic eSpherical ye-Foundry

Ipropati yeSanti yeCeramic

| ICandelo leMichiza eliPhambili | Al₂O₃≥53%, Fe₂O₃<4%, TiO₂<3%, SiO₂≤37% |

| Imilo yeenkozo | I-Spherical |

| I-Angular Coefficient | ≤1.1 |

| Ubungakanani obuyinxenye | 45μm -2000μm |

| Ukuchasa | ≥1800℃ |

| Unizi lolwapho kuyiwa khona | 1.5-1.6 g/cm3 |

| Ukwandiswa kweThermal (RT-1200℃) | 4.5-6.5x10-6/k |

| Umbala | Isanti |

| PH | 6.6-7.3 |

| Ukuqulunqwa kweMineralogical | Ithambile + iCorundum |

| Iindleko ze-Acid | <1 ml/50g |

| LOI | <0.1% |

Inzuzo

● Intlabathi eluhlaza. IKHUSELEKILE kwindawo engqongileyo xa kuthelekiswa ne-silica (silicosis) kunye nesanti ye-zircon

● High refractoriness (>1800°C),can be used for casting various materials. There is also no need to use different sand type according to material.

● Izinga eliphezulu lokubuyisela. Zombini i-Thermal kunye ne-mechanical reclamation. Inika ubomi obude bomsebenzi kunye nokunciphisa ukusetyenziswa kwesanti.

● Ukugoba okuphezulu. Isanti yeCeramic esintered imilo engqukuva xa ithelekiswa neenkozo ezimilise okwe-angular ivumela ukwahlulwa lula kwiindawo ezisasisiweyo kunye nokuphucula ukubola okukhokelela kwi-scrap esezantsi kunye nokusebenza kakuhle kokuphosa.

● Ubumanzi obugqwesileyo kunye nokusebenza kakuhle kokuzalisa ngenxa yokuba singqukuva.

● Ukwandiswa kwe-Thermal ephantsi kunye ne-Thermal Conductivity. Imilinganiselo yokuphosa ichaneke ngakumbi kwaye i-conductivity ephantsi ibonelela ngokusebenza okungcono kokungunda.

● Ubuninzi bobuninzi obusezantsi. Njengoko isanti eyenziweyo yeceramic yokwenziwa imalunga nesiqingatha sokukhanya njengesanti yeseramikhi edityanisiweyo (isanti yebhola emnyama), i-zircon kunye nekhromite, inokujika malunga nenani eliphindwe kabini lemold yeyunithi nganye. Inokusingathwa ngokulula kakhulu, ukonga abasebenzi kunye neendleko zamandla okudluliselwa. Nangona kunjalo, ingqwalasela kufuneka inikwe kwisixa sokudibanisa isibophelelo.

● Ifuna i-40-50% ngaphantsi kwe-resin.

● Iicasta ziqatywe nge-coat encinci okanye zingabikho.

● Inokusetyenziswa njengesanti enye.

● Unikezelo oluzinzileyo. Umthamo wonyaka we-200,000 MT ukugcina unikezelo olukhawulezayo noluzinzileyo.

Isicelo

Njengezinto ezingathathi hlangothi, isanti ye-ceramic ye-KAIST iyasebenza kwi-asidi kunye ne-alkali resins.

Ingasetyenziselwa ngokubanzi intsimbi etyhidiweyo, intsimbi etyhidiweyo kunye neentsimbi ezingezizo, ezifana nokuphosa amagwebu alahlekileyo, isanti egqunyiweyo, isanti yeresin, ibhokisi engundoqo ebandayo, ukuphosa ngokuchanekileyo, kunye noshicilelo lwe-3D.

Iinxalenye zoSabelo lobungakanani beNcam

Ukuhanjiswa kobungakanani besuntswana kunokwenziwa ngokwezifiso ngokwemfuno yakho.

|

Umnatha |

20 | 30 | 40 | 50 | 70 | 100 | 140 | 200 | 270 | Ipani | AFS | |

|

μm |

850 | 600 | 425 | 300 | 212 | 150 | 106 | 75 | 53 | Ipani | ||

| Ikhowudi | 20/40 | 15-40 | 30-55 | 15-35 | ≤5 | 20±5 | ||||||

| 30/50 | ≤1 | 25-35 | 35-50 | 15-25 | ≤10 | ≤1 | 30±5 | |||||

| 40/70 | ≤5 | 20-30 | 40-50 | 15-25 | ≤8 | ≤1 | 43±3 | |||||

| 70/40 | ≤5 | 15-25 | 40-50 | 20-30 | ≤10 | ≤2 | 46±3 | |||||

| 50/100 | ≤5 | 25-35 | 35-50 | 15-25 | ≤6 | ≤1 | 50±3 | |||||

| 100/50 | ≤5 | 15-25 | 35-50 | 25-35 | ≤10 | ≤1 | 55±3 | |||||

| 70/140 | ≤5 | 25-35 | 35-50 | 8-15 | ≤5 | ≤1 | 65±4 | |||||

| 140/70 | ≤5 | 15-35 | 35-50 | 20-25 | ≤8 | ≤2 | 70±5 | |||||

| 100/200 | ≤10 | 20-35 | 35-50 | 15-20 | ≤10 | ≤2 | 110±5 | |||||

Iindidi zeemveliso