- Afrikaan

- Albaaniyaan

- Amxaari

- Carabi

- Armeeniyaan

- Asarbayjaan

- Basque

- Belarusiyaanka

- Bengali

- Bosnia

- Bulgaariya

- Catalan

- Cebuano

- Shiinaha

- Shiinaha (Taiwan)

- Korsican

- Croatian

- Czech

- Danish

- Dutch

- Ingiriis

- Esperanto

- Istooniyaan

- Finnish

- Faransiis

- Frisian

- Galiciyan

- Joorjiyaan

- Jarmal

- Giriig

- Gujarati

- Haitian Creole

- hausa

- hawiye

- Cibraaniga

- Maya

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- iriish

- Talyaani

- Jabbaan

- Javanese

- Kannada

- Kazakh

- Khmer

- Ruwanda

- Kuuriyaan

- Kurdish

- Kyrgyz

- Qaaxo

- Laatiinka

- Latvia

- Lithuanian

- Luxembourgish

- Masedooniyaan

- Malgashi

- Malaay

- Malayalam

- Malta

- Maori

- Marathi

- Mongoliyaan

- Myanmar

- Nepali

- Noorwiiji

- Noorwiiji

- Occitan

- Pashto

- Faaris

- Polish

- Boortaqiis

- Punjabi

- Romanian

- Ruush

- Samoan

- Scottish Gaelic

- Seerbiyaan

- Ingiriis

- Shona

- Sindhi

- Sinhala

- Slovakia

- Islovenian

- Somali

- Isbaanish

- Sundanese

- Sawaaxili

- Iswidish

- Tagalog

- Taajik

- Tamil

- Tataarka

- Telugu

- Thai

- Turki

- Turkmen

- Yukreeniyaan

- Urduu

- Uighur

- Uzbekistan

- Vietnamese

- Welsh

- I caawi

- Yiddish

- Yurub

- Zulu

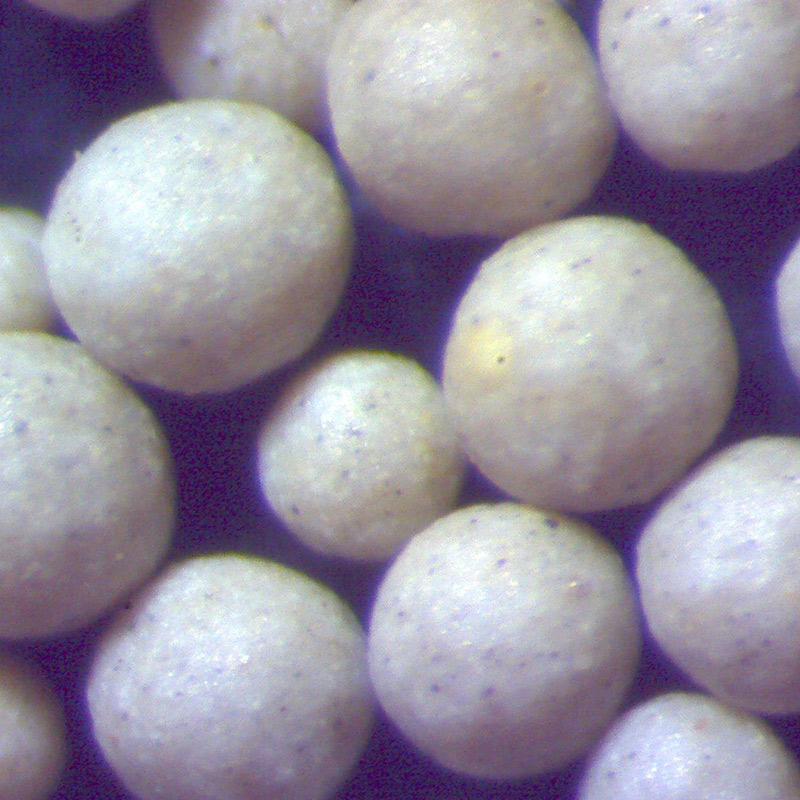

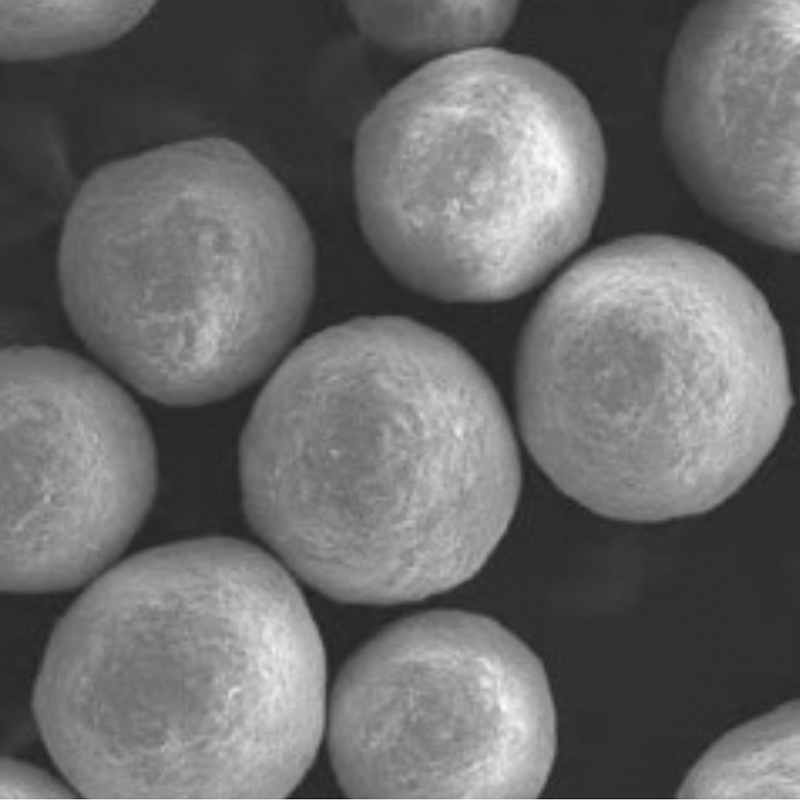

Ciidda Ceramic Spherical ee Aasaaska

Hantida Ciidda dhoobada

| Qaybta Kiimikada ugu weyn | Al₂O₃≥53%, Fe₂O₃<4%, TiO₂<3%, SiO₂≤37% |

| Qaabka hadhuudhka | Goobaysan |

| Iskuxidhka xagal | ≤1.1 |

| Cabirka Qayb ahaan | 45μm -2000μm |

| Refractority | ≥1800℃ |

| Cufnaanta Bulk | 1.5-1.6 g/cm3 |

| Balaadhinta kulaylka (RT-1200℃) | 4.5-6.5x10-6/k |

| Midabka | Ciid |

| PH | 6.6-7.3 |

| Halabuurka macdanta | Jilicsan + Corundum |

| Qiimaha aysiidhka | <1 ml/50g |

| LOI | 0.1% |

Faa'iidada

● Ciid cagaaran. Badbaadada deegaanka marka la barbar dhigo silica (silicosis) iyo ciid zircon

● High refractoriness (>1800°C),can be used for casting various materials. There is also no need to use different sand type according to material.

● Heerka dib u soo celinta oo sarreeya. Dib u soo celinta kulaylka iyo farsamada labadaba. Waxay bixisaa nolol shaqo oo dheer iyo dhimista isticmaalka ciidda.

● Burbur sare. Bacaadka sintered Ceramic spherical qaabka marka la barbar dhigo badarka qaabka xagal leh ayaa u ogolaanaya in si sahlan looga sooco qaybaha kabka iyo kor u kaca burburka taasoo keentay in qashinka hoose iyo waxtarka shubista.

● Dheecaan aad u wanaagsan iyo hufnaanta buuxinta taasoo ay ugu wacan tahay qaab-dhismeedka.

● Balaadhinta kulaylka hoose iyo habdhaqanka kulaylka. Cabbiraadaha tuurista ayaa aad u saxsan, isla markaana hoos u dhigista tayada ayaa bixisa waxqabadka caaryada wanaagsan.

● Cufnaanta cufnaanta hoose. Sida ciidda dhoobada macmalka ah ay kala badh le'eg tahay sida ciid dhoobada isku dhafan (cidka kubbadda madow), zircon iyo chromite, waxay soo noqon kartaa qiyaastii laba jeer tirada caaryada ee miisaankiiba. Waxa kale oo loo maareyn karaa si fudud, iyada oo la badbaadinayo shaqada iyo kharashka wareejinta. Si kastaba ha ahaatee, fiiro gaar ah waa in la siiyaa qadarka ku darista binder.

● Waxay u baahan tahay 40-50% xabagta ka yar.

● Kabadaha waxaa lagu dahaadhay wax yar ama aan lahayn dahaar.

● Waxa loo isticmaali karaa sidii hal bacaad ah.

● Sahayda deggan. Awood sannadeedka 200,000 MT si loo ilaaliyo sahayda degdega ah oo deggan.

Codsiga

Sida walxo dhexdhexaad ah, ciid dhoobada KAIST waa mid lagu dabaqi karo aashitada iyo alkali.

Waxaa si weyn loogu isticmaali karaa shubista birta, birta shubka iyo biraha aan biraha lahayn, sida tuurista xumbo luntay, ciid dahaarka leh, ciid resin, sanduuqa xudunta u ah qabow, shubista saxda ah, iyo daabacaadda 3D.

Qaybaha Cabbirka Qaybaha Qaybinta

Qaybinta cabbirka walxaha waxaa lagu habeyn karaa iyadoo loo eegayo baahidaada.

|

Mesh |

20 | 30 | 40 | 50 | 70 | 100 | 140 | 200 | 270 | digsi | AFS | |

|

μm |

850 | 600 | 425 | 300 | 212 | 150 | 106 | 75 | 53 | digsi | ||

| Koodhka | 20/40 | 15-40 | 30-55 | 15-35 | ≤5 | 20±5 | ||||||

| 30/50 | ≤1 | 25-35 | 35-50 | 15-25 | ≤10 | ≤1 | 30±5 | |||||

| 40/70 | ≤5 | 20-30 | 40-50 | 15-25 | ≤8 | ≤1 | 43±3 | |||||

| 70/40 | ≤5 | 15-25 | 40-50 | 20-30 | ≤10 | ≤2 | 46±3 | |||||

| 50/100 | ≤5 | 25-35 | 35-50 | 15-25 | ≤6 | ≤1 | 50±3 | |||||

| 100/50 | ≤5 | 15-25 | 35-50 | 25-35 | ≤10 | ≤1 | 55±3 | |||||

| 70/140 | ≤5 | 25-35 | 35-50 | 8-15 | ≤5 | ≤1 | 65±4 | |||||

| 140/70 | ≤5 | 15-35 | 35-50 | 20-25 | ≤8 | ≤2 | 70±5 | |||||

| 100/200 | ≤10 | 20-35 | 35-50 | 15-20 | ≤10 | ≤2 | 110±5 | |||||

Qaybaha alaabta