- Moafrika

- Sealbania

- Seamharic

- Searabia

- Searmenia

- Se-Azerbaijani

- Sebasque

- Sebelarusia

- Benghali

- Sebosnia

- Se-Bulgaria

- Secatalan

- Sebuano

- China

- China (Taiwan)

- Corsican

- Secroatia

- Czech

- Sedanishe

- Se-Dutch

- Senyesemane

- Esperanto

- Seestonia

- Sefinnishe

- Sefora

- Sefrisia

- Segalician

- Segeorgia

- Sejeremane

- Segerike

- Segujarati

- Secreole sa Haiti

- hausa

- siwaiian

- Seheberu

- Che

- Miao

- Se-Hungary

- Seiceland

- igbo

- Seindonesia

- irish

- Setaliana

- Sejapane

- Se-Javanese

- Kannada

- kazakh

- Khmer

- Rwanda

- Sekorea

- Sekurdish

- Sekyrgyz

- Lefuba

- Selatine

- Selatvia

- Selithuania

- Se-Luxembourgish

- Semacedonia

- Malgashi

- Semalay

- Semalayalam

- Semalta

- Semaori

- Marathi

- Mongolian

- Myanmar

- tsa Nepali

- Norwegian

- Norwegian

- Occitan

- Sepashto

- Sepersia

- Sepolishe

- Sepotoketsi

- Sepunjabi

- Seromania

- Serussia

- Sesamoa

- Segaeli sa Scotland

- Seserbia

- Senyesemane

- Seshona

- Sindhi

- Sesinhala

- Seslovak

- Seslovenia

- Somalia

- Sepanish

- Sesundanese

- Seswahili

- Seswedishe

- Setagalog

- Se-Tajik

- Setamil

- Setatare

- Setelugu

- Sethai

- Se-Turkey

- Turkmen

- Seukraine

- Seurdu

- Uighur

- Seuzbek

- Sevietnam

- Welsh

- Thusa

- Yiddish

- Yoruba

- Sezulu

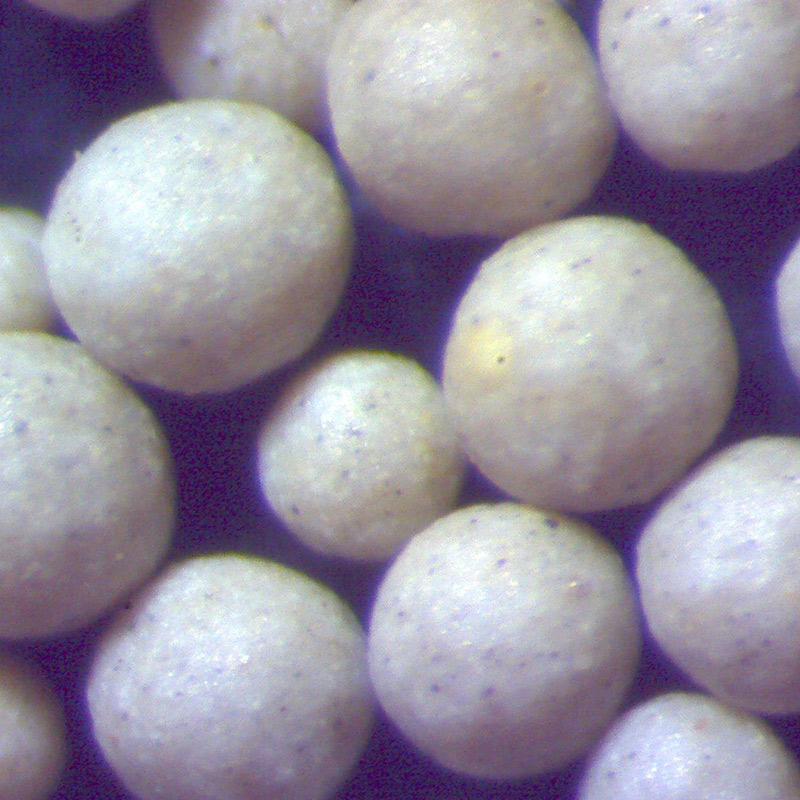

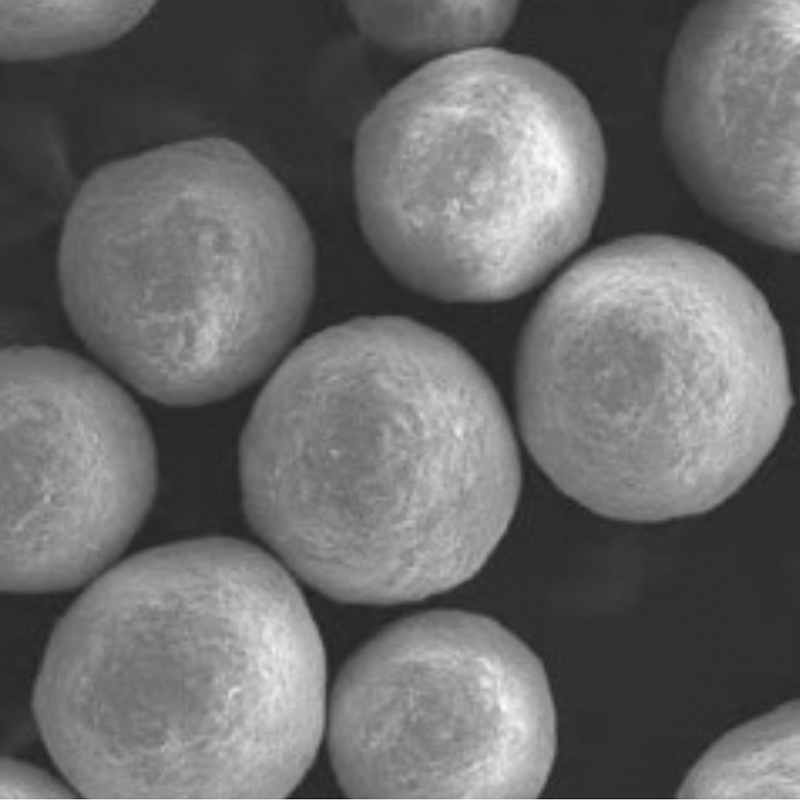

Spherical Ceramic Sand bakeng sa Foundry

Thepa ea Lehlabathe la Ceramic

| Karolo e ka Sehloohong ea Lik'hemik'hale | Al₂O₃≥53%, Fe₂O₃<4%, TiO₂<3%, SiO₂≤37% |

| Sebopeho sa lijo-thollo | Spherical |

| Angular Coefficient | ≤1.1 |

| Boholo bo sa Lekaneng | 45μm -2000μm |

| Refractoriness | ≥1800℃ |

| Boima ba Bongata | 1.5-1.6 g/cm3 |

| Katoloso ea Thermal (RT-1200℃) | 4.5-6.5x10-6/k |

| Mmala | Lehlabathe |

| PH | 6.6-7.3 |

| Sebopeho sa Mineralogical | E bonolo + Corundum |

| Litšenyehelo tsa Asiti | <1 ml/50g |

| LOI | <0.1% |

Molemo

● Lehlabathe le Letala. E SIRELETSE tikolohong ha e bapisoa le silica (silicosis) le lehlabathe la zircon

● High refractoriness (>1800°C),can be used for casting various materials. There is also no need to use different sand type according to material.

● Sekhahla se phahameng sa ho khutlisa chelete. Ka bobeli Thermal le mochini reclamation. E fana ka bophelo bo bolelele ba mosebetsi le phokotso ea tšebeliso ea lehlabathe.

● Ho senyeha ho hoholo. Sebōpeho se chitja sa lehlabathe la Sintered Ceramic ha le bapisoa le lithollo tse nang le sebopeho sa angular se lumella karohano e bonolo ho tsoa ho likarolo tse lahliloeng le ho putlama ho ntlafalitsoeng ho fellang ka matla a tlase le bokhoni ba ho lahlela.

● Mokelikeli o babatsehang le bokhoni ba ho tlatsa ka lebaka la ho ba chitja.

● Katoloso e tlase ea Thermal le Thermal Conductivity. Litekanyo tsa ho lahla li nepahetse haholoanyane mme conductivity e tlase e fana ka ts'ebetso e ntle ea hlobo.

● Tšebeliso e tlaase ea bongata. Joalo ka ha lehlabathe la maiketsetso le le bobebe ho feta lehlabathe la ceramic le kopantsoeng (lehlabathe la bolo e ntšo), zircon le chromite, le ka fetoha habeli palo ea hlobo ka boima ba yuniti. E ka boela ea sebetsoa habonolo haholo, e boloka litšenyehelo tsa basebetsi le ho fetisetsa matla a motlakase. Leha ho le joalo, tlhokomelo e lokela ho lebisoa ho palo ea tlatsetso ea binder.

● E hloka 40-50% e fokolang ea resin.

● Li-casting li koahetsoe ka liphahlo tse nyenyane kapa li se na letho.

● E ka sebelisoa e le lehlabathe le le leng.

● Phepelo e tsitsitseng. Bokhoni ba selemo ba 200,000 MT ho boloka phepelo e potlakileng le e tsitsitseng.

Kopo

Joalo ka thepa e sa nke lehlakore, lehlabathe la ceramic la KAIST le sebetsa ho li-resin tsa acid le alkali.

E ka sebelisoa haholo bakeng sa tšepe e entsoeng ka tšepe, tšepe e entsoeng ka tšepe le tšepe e sa tsitsang, joalo ka ho lahlela foam e lahlehileng, lehlabathe le koahetsoeng, lehlabathe la resin, lebokose le batang la mantlha, ho lahla ka nepo, le khatiso ea 3D.

Likarolo tsa Kabo ea boholo ba Particle

Kabo ea boholo ba phatsa e ka etsoa ho latela tlhoko ea hau.

|

Mesh |

20 | 30 | 40 | 50 | 70 | 100 | 140 | 200 | 270 | Pan | AFS | |

|

μm |

850 | 600 | 425 | 300 | 212 | 150 | 106 | 75 | 53 | Pan | ||

| Khoutu | 20/40 | 15-40 | 30-55 | 15-35 | ≤5 | 20±5 | ||||||

| 30/50 | ≤1 | 25-35 | 35-50 | 15-25 | ≤10 | ≤1 | 30±5 | |||||

| 40/70 | ≤5 | 20-30 | 40-50 | 15-25 | ≤8 | ≤1 | 43±3 | |||||

| 70/40 | ≤5 | 15-25 | 40-50 | 20-30 | ≤10 | ≤2 | 46±3 | |||||

| 50/100 | ≤5 | 25-35 | 35-50 | 15-25 | ≤6 | ≤1 | 50±3 | |||||

| 100/50 | ≤5 | 15-25 | 35-50 | 25-35 | ≤10 | ≤1 | 55±3 | |||||

| 70/140 | ≤5 | 25-35 | 35-50 | 8-15 | ≤5 | ≤1 | 65±4 | |||||

| 140/70 | ≤5 | 15-35 | 35-50 | 20-25 | ≤8 | ≤2 | 70±5 | |||||

| 100/200 | ≤10 | 20-35 | 35-50 | 15-20 | ≤10 | ≤2 | 110±5 | |||||

Lihlopha tsa lihlahisoa