- Afirka

- Albaniya

- Amharic

- Larabci

- Armenian

- Azerbaijan

- Basque

- Belarushiyanci

- Bengali

- Bosniya

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Yaren mutanen Holland

- Turanci

- Esperanto

- Estoniya

- Finnish

- Faransanci

- Farisa

- Galiciyan

- Jojin

- Jamusanci

- Girkanci

- Gujarati

- Haitian Creole

- hausa

- hawayi

- Ibrananci

- A'a

- Miya

- Harshen Hungary

- Icelandic

- igbo

- Indonesiya

- Irish

- Italiyanci

- Jafananci

- Yawanci

- Kannada

- kazakh

- Khmer

- Ruwanda

- Yaren Koriya

- Kurdish

- Kyrgyzstan

- TB

- Latin

- Latvia

- Lithuaniyanci

- Luxembourgish

- Makidoniya

- Malgashi

- Malay

- Malayalam

- Maltase

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Yaren mutanen Norway

- Yaren mutanen Norway

- Occitan

- Pashto

- Farisa

- Yaren mutanen Poland

- Fotigal

- Punjabi

- Romanian

- Rashanci

- Samoan

- Scottish Gaelic

- Serbian

- Turanci

- Shona

- Sindhi

- Sinhala

- Slovak

- Harshen Sloveniya

- Somaliya

- Mutanen Espanya

- Sundanci

- Harshen Swahili

- Yaren mutanen Sweden

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Baturke

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Taimako

- Yadish

- Yarbawa

- Zulu

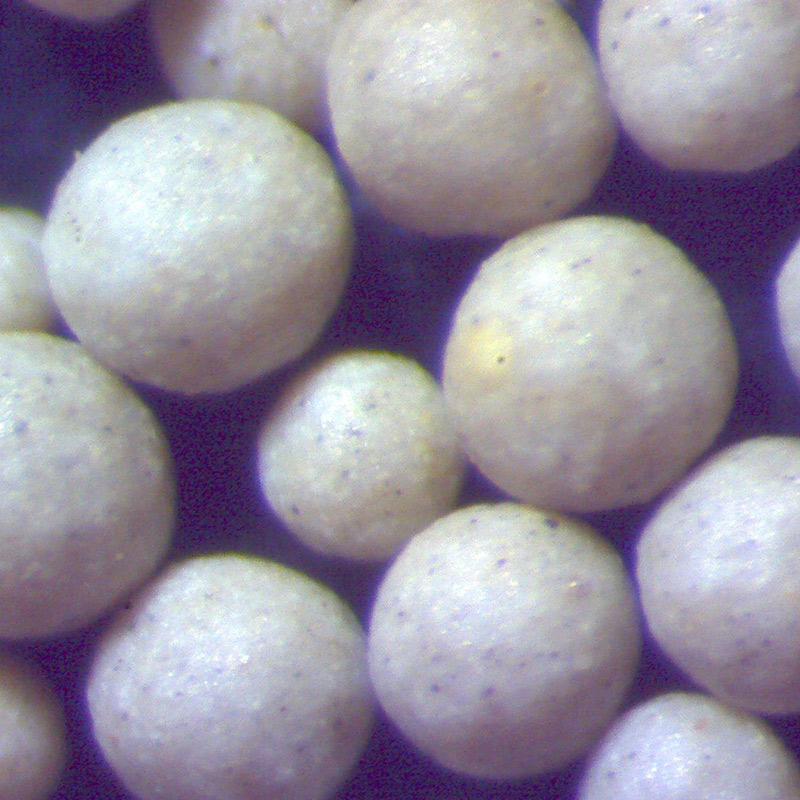

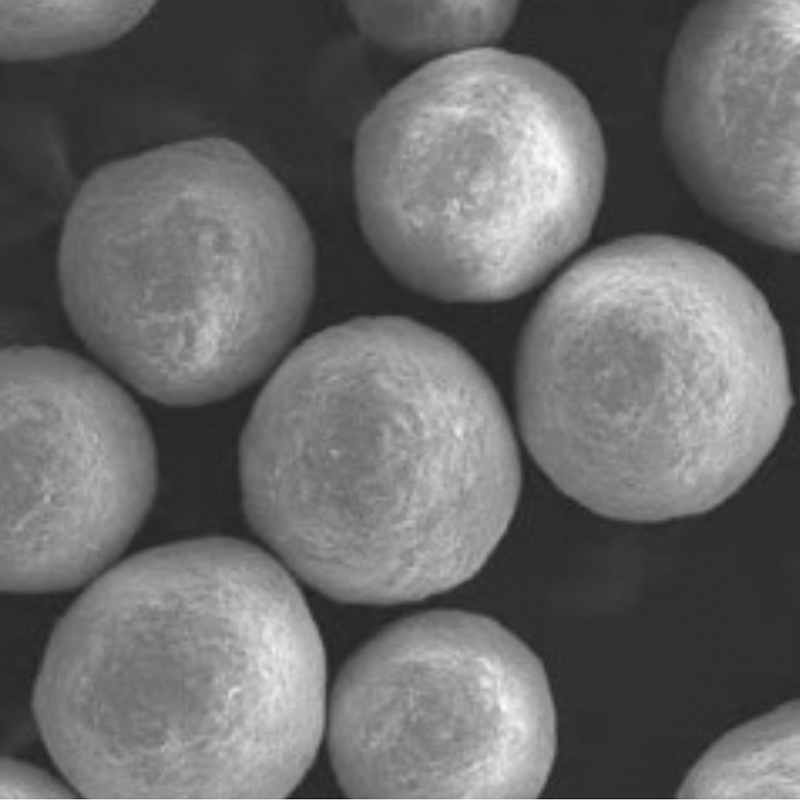

Spherical Ceramic Sand don Foundry

Abubuwan Yashi na yumbu

| Babban Abun Sinadari | Al₂O₃≥53%, Fe₂O₃<4%, TiO₂<3%, SiO₂≤37% |

| Siffar hatsi | Siffar |

| Angular Coefficient | ≤1.1 |

| Girman Juzu'i | 45μm -2000μm |

| Refractoriness | ≥1800℃ |

| Yawan yawa | 1.5-1.6 g/cm3 |

| Thermal Fadada (RT-1200℃) | 4.5-6.5x10-6/k |

| Launi | Yashi |

| PH | 6.6-7.3 |

| Ma'adinan Ma'adinai | Soft + Corundum |

| Farashin Acid | <1 ml/50g |

| LOI | 0.1% |

Amfani

● Koren Yashi. SAFE ga muhalli idan aka kwatanta da silica (silicosis) da yashi zircon

● High refractoriness (>1800°C),can be used for casting various materials. There is also no need to use different sand type according to material.

● Matsakaicin sakewa. Dukansu Thermal da na inji reclamation. Yana ba da tsawon rayuwar aiki da rage yawan amfani da yashi.

● Babban haɗuwa. Siffar yashin yashin Sintered wanda aka kwatanta da nau'in nau'in nau'in nau'in kusurwa yana ba da damar sauƙi don rabuwa daga sassan simintin gyare-gyare da ingantacciyar karɓuwa wanda ke haifar da ƙananan juzu'i da ingantaccen simintin.

● Ƙwararren ruwa da cika iya aiki saboda kasancewa mai siffa.

● ƙananan fadada da kuma ƙwararren yanayin zafi. Girman simintin gyare-gyare sun fi daidai kuma ƙananan ƙarfin aiki yana ba da kyakkyawan aikin ƙira.

● Ƙananan girma mai yawa. Kamar yadda yashi yumbu na wucin gadi ya kusan rabin haske kamar yashin yumbu mai gauraya (yashin ball baƙar fata), zircon da chromite, yana iya juyawa kusan sau biyu adadin ƙira na kowane nauyin raka'a. Hakanan za'a iya sarrafa shi cikin sauƙi, ceton aiki da canja wurin kuɗin wutar lantarki. Koyaya, ya kamata a ba da hankali ga adadin ƙari.

● Yana buƙatar ƙarancin guduro 40-50%.

● Ana lulluɓe simintin gyare-gyare tare da ɗan ƙarami ko babu.

Ana iya amfani da shi azaman yashi ɗaya.

● Samar da kwanciyar hankali. Ikon shekara-shekara 200,000 MT don kiyaye wadatar da sauri da kwanciyar hankali.

Aikace-aikace

A matsayin tsaka tsaki abu, KAIST yumbu yashi yana da amfani ga acid da alkali resins.

Ana iya amfani dashi ko'ina don yin simintin ƙarfe, simintin ƙarfe da simintin ƙarfe mara ƙarfe, kamar simintin kumfa da aka ɓace, yashi mai rufi, yashi guduro, akwatin babban sanyi, daidaitaccen simintin simintin, da bugu na 3D.

Sassan Rarraba Girman Barbashi

Za'a iya daidaita girman girman barbashi bisa ga buƙatun ku.

|

raga |

20 | 30 | 40 | 50 | 70 | 100 | 140 | 200 | 270 | Pan | Farashin AFS | |

|

μm |

850 | 600 | 425 | 300 | 212 | 150 | 106 | 75 | 53 | Pan | ||

| Lambar | 20/40 | 15-40 | 30-55 | 15-35 | ≤5 | 20±5 | ||||||

| 30/50 | ≤1 | 25-35 | 35-50 | 15-25 | ≤10 | ≤1 | 30±5 | |||||

| 40/70 | ≤5 | 20-30 | 40-50 | 15-25 | ≤8 | ≤1 | 43±3 | |||||

| 70/40 | ≤5 | 15-25 | 40-50 | 20-30 | ≤10 | ≤2 | 46±3 | |||||

| 50/100 | ≤5 | 25-35 | 35-50 | 15-25 | ≤6 | ≤1 | 50±3 | |||||

| 100/50 | ≤5 | 15-25 | 35-50 | 25-35 | ≤10 | ≤1 | 55±3 | |||||

| 70/140 | ≤5 | 25-35 | 35-50 | 8-15 | ≤5 | ≤1 | 65±4 | |||||

| 140/70 | ≤5 | 15-35 | 35-50 | 20-25 | ≤8 | ≤2 | 70±5 | |||||

| 100/200 | ≤10 | 20-35 | 35-50 | 15-20 | ≤10 | ≤2 | 110±5 | |||||

Rukunin samfuran