- Afrika

- Albania

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Asụsụ Bosnia

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Asụsụ Croatia

- Czech

- Danish

- Dutch

- Bekee

- Esperanto

- Estonia

- Asụsụ Finnish

- French

- Onye Frisian

- Onye Galisi

- Asụsụ Georgian

- German

- Grik

- Gujarati

- Haitian Creole

- hausa

- Hawaian

- Hibru

- Mba

- Miao

- Asụsụ Hungarian

- Aislandi

- igbo

- Asụsụ Indonesian

- Irish

- Ịtali

- Japanese

- Asụsụ Javanị

- Kannada

- kazakh

- Khmer

- Onye Rwandan

- Korean

- Kurdish

- Kyrgyz

- TB

- Latịn

- Latvia

- Lithuania

- Luxembourgish

- Masedonia

- Malgashi

- Malay

- Malayalam

- Malta

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Asụsụ Persia

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Asụsụ Serbian

- Bekee

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Asụsụ Sudan

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- onye Ukraine

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Enyemaka

- Yiddish

- Yoruba

- Zulu

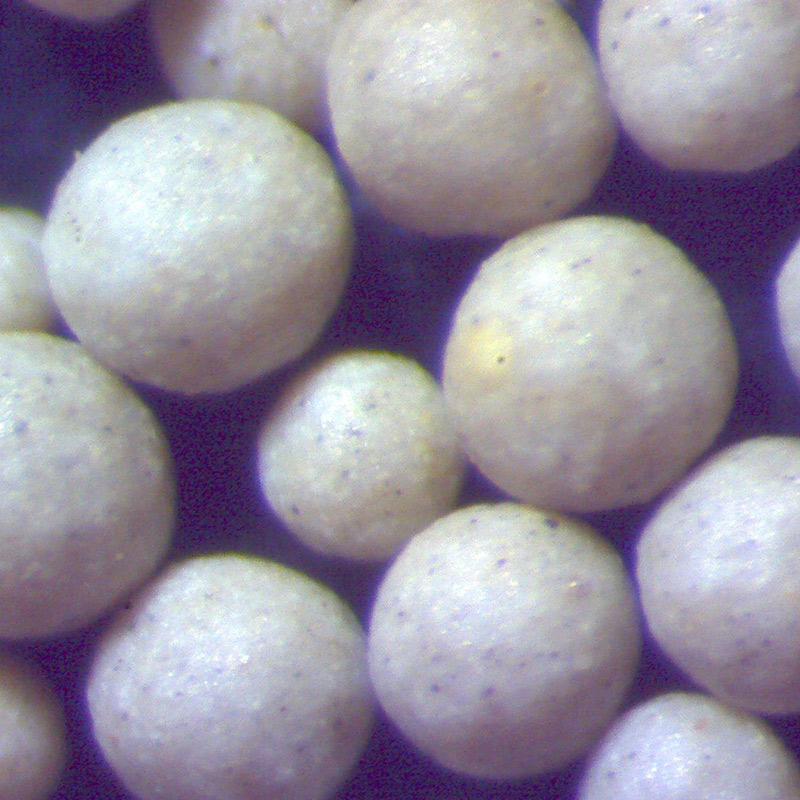

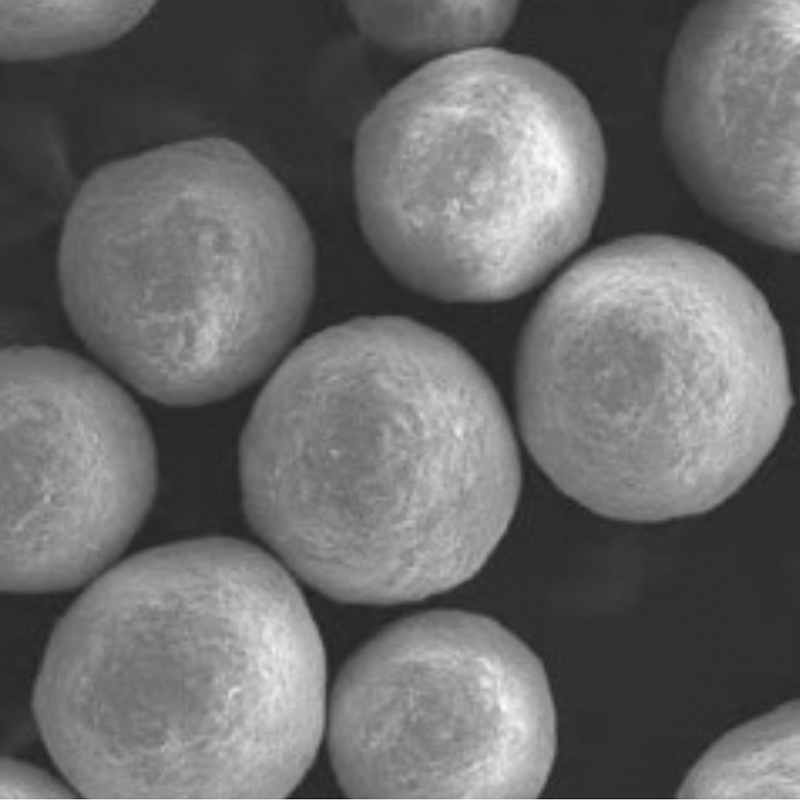

Spherical Ceramic ájá maka ntọala ntọala

Ihe onwunwe seramiiki

| Ihe mejupụtara kemịkalụ bụ isi | Al₂O₃≥53%, Fe₂O₃<4%, TiO₂<3%, SiO₂≤37% |

| Ụdị ọka | Spherical |

| Ọnụ ego angular | ≤1.1 |

| Akụkụ akụkụ | 45μm -2000μm |

| Refractoriness | ≥1800℃ |

| Njupụta nnukwu | 1.5-1.6 g/cm3 |

| Mgbasa ọkụ (RT-1200℃) | 4.5-6.5x10-6/k |

| Agba | Aja |

| PH | 6.6-7.3 |

| Ihe mejupụtara mineral | Dị nro + Corundum |

| Ọnụ ego acid | <1 ml/50g |

| LOI | 0.1% |

Uru

● Aja akwụkwọ ndụ akwụkwọ ndụ. Nchekwa gburugburu ebe obibi ma e jiri ya tụnyere silica (silicosis) na ájá zircon

● High refractoriness (>1800°C),can be used for casting various materials. There is also no need to use different sand type according to material.

● Ọnụ ọgụgụ mweghachi dị elu. Ma Thermal na nrụgharị igwe. Na-enye ogologo ndụ ọrụ yana mbelata ojiji ájá.

● Nnukwu ndakpọ. Udi okirikiri ájá seramiiki gbanyere mkpọrọgwụ ma e jiri ya tụnyere mkpụrụ osisi nwere nkuku na-enye ohere ikewapụ mfe na akụkụ nkedo yana mbelata ndakọrịta na-ebute obere mkpofu na ịrụ ọrụ nkedo.

● Mmiri dị mma na njuputa arụmọrụ n'ihi ịdị okirikiri.

● Lower Thermal Mgbasawanye na Thermal Conductivity. Akụkụ nkedo bụ nke ziri ezi na arụmọrụ dị ala na-enye arụmọrụ ebu ka mma.

● Njupụta dị ala. Dị ka ájá seramiiki wuruwuru dị ihe dị ka ọkara ka ìhè dị ka ájá seramiiki fused (aja ojii ojii), zircon na chromite, ọ nwere ike ịpụta ihe dị ka okpukpu abụọ nke ebu kwa otu nha. Enwere ike ijikwa ya n'ụzọ dị mfe, na-echekwa ọrụ na ịnyefe ego ike. Otú ọ dị, ekwesịrị itinye nlebara anya na ọnụọgụ nke mgbakwunye.

● Achọrọ 40-50% obere resin.

● A na-eji obere ihe kpuchie ihe nkedo ma ọ bụ na-enweghị ihe mkpuchi.

● Enwere ike iji ya mee otu ájá.

● Ọdụdọ kwụsiri ike. Ikike kwa afọ 200,000 MT iji dobe ngwa ngwa ma kwụsie ike.

Ngwa

Dị ka ihe na-anọpụ iche, KAIST seramiiki ájá na-adabara acid na alkali resins.

Enwere ike iji ya mee ihe n'ọtụtụ ebe maka igwe nkedo, ihe nkedo na igwe anaghị agba nchara, dị ka nkedo ụfụfụ furu efu, ájá mkpuchi, aja resin, igbe isi oyi, nkedo ziri ezi, na mbipụta 3D.

Akụkụ nke nkesa nha nha

Enwere ike ịhazi nkesa nha nha dị ka ihe ị chọrọ.

|

Ntupu |

20 | 30 | 40 | 50 | 70 | 100 | 140 | 200 | 270 | Pan | AFS | |

|

μm |

850 | 600 | 425 | 300 | 212 | 150 | 106 | 75 | 53 | Pan | ||

| Koodu | 20/40 | 15-40 | 30-55 | 15-35 | ≤5 | 20±5 | ||||||

| 30/50 | ≤1 | 25-35 | 35-50 | 15-25 | ≤10 | ≤1 | 30±5 | |||||

| 40/70 | ≤5 | 20-30 | 40-50 | 15-25 | ≤8 | ≤1 | 43±3 | |||||

| 70/40 | ≤5 | 15-25 | 40-50 | 20-30 | ≤10 | ≤2 | 46±3 | |||||

| 50/100 | ≤5 | 25-35 | 35-50 | 15-25 | ≤6 | ≤1 | 50±3 | |||||

| 100/50 | ≤5 | 15-25 | 35-50 | 25-35 | ≤10 | ≤1 | 55±3 | |||||

| 70/140 | ≤5 | 25-35 | 35-50 | 8-15 | ≤5 | ≤1 | 65±4 | |||||

| 140/70 | ≤5 | 15-35 | 35-50 | 20-25 | ≤8 | ≤2 | 70±5 | |||||

| 100/200 | ≤10 | 20-35 | 35-50 | 15-20 | ≤10 | ≤2 | 110±5 | |||||

Ụdị ngwaahịa