- Afirika

- Chialubaniya

- Chiamharic

- Chiarabu

- Chiameniya

- Chiazerbaijani

- Basque

- Chibelarusi

- Chibengali

- Chibosnia

- Chibugariya

- Chikatalani

- Cebuano

- China

- China (Taiwan)

- Chikosikani

- Chikroatia

- Chicheki

- Chidanishi

- Chidatchi

- Chingerezi

- Chiesperanto

- Chiestonia

- Chifinishi

- Chifalansa

- Chifrisian

- Chigalikiya

- Chijojiya

- Chijeremani

- Chigriki

- Gujarati

- Chikiliyo cha ku Haiti

- hausa

- Hawaii

- Chiheberi

- Ayi

- Miao

- Chihangare

- Chi Icelandic

- igbo

- Chi Indonesian

- ayi

- Chitaliyana

- Chijapani

- Chijavani

- Kanada

- kazakh

- Khmer

- Rwanda

- Chikorea

- Chikurdi

- Kyrgyz

- TB

- Chilatini

- Chilativiya

- Chilithuania

- ChiLuxembourgish

- Chimakedoniya

- Malgashi

- Chimalayi

- Malayalam

- Chimalta

- Chimaori

- Chimarathi

- Chimongoliya

- Myanmar

- Chinepali

- Chinorwe

- Chinorwe

- Occitan

- Pashto

- Chiperisi

- Chipolishi

- Chipwitikizi

- Chipunjabi

- Chiromania

- Chirasha

- Chisamoa

- Scottish Gaelic

- Chisebiya

- Chingerezi

- Chishona

- Sindi

- Sinhala

- Chisilovaki

- Chisiloveniya

- Somalia

- Chisipanishi

- Chisundanese

- Swahili

- Chiswidishi

- Chitagalogi

- Tajiki

- Tamil

- Chitata

- Telugu

- Thai

- Turkey

- Turkmen

- Chiyukireniya

- Chiurdu

- Uighur

- Chiuzbeki

- Vietnamese

- Welsh

- Thandizeni

- Chiyidi

- Chiyoruba

- Chizulu

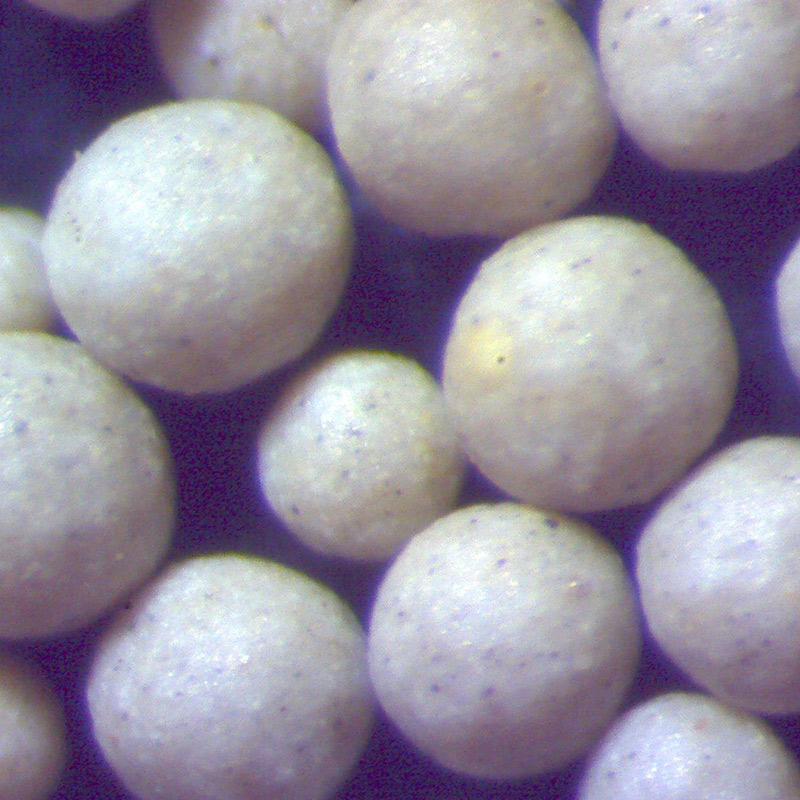

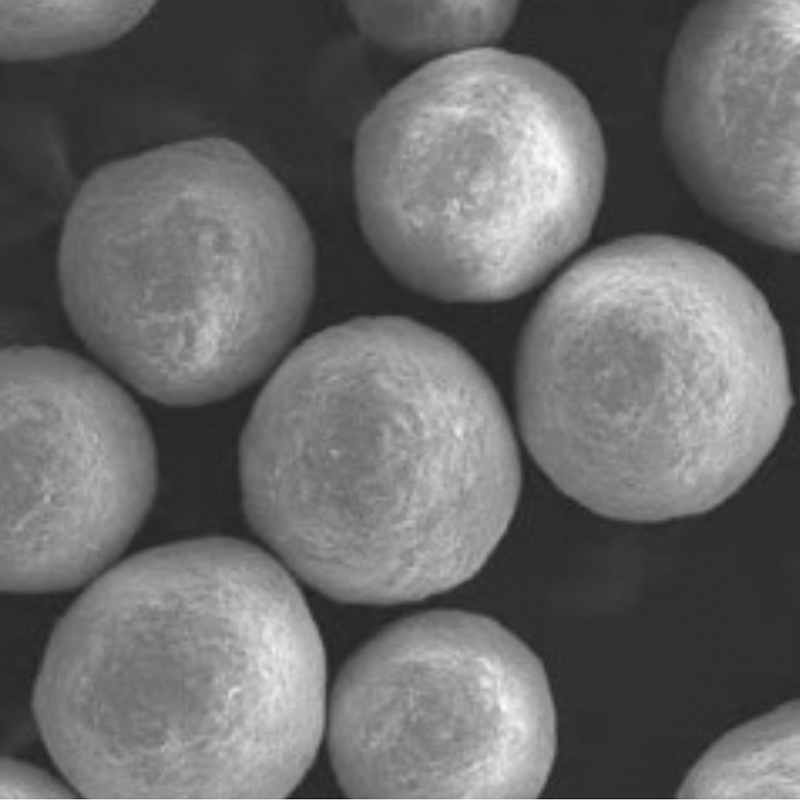

Spherical Ceramic Sand for Foundry

Ceramic Sand Property

| Main Chemical Chigawo | Al₂O₃≥53%, Fe₂O₃<4%, TiO₂<3%, SiO₂≤37% |

| Maonekedwe a Mbewu | Chozungulira |

| Angular Coefficient | ≤1.1 |

| Kukula Kwambiri | 45μm -2000μm |

| Refractoriness | ≥1800℃ |

| Kuchulukana Kwambiri | 1.5-1.6 g/cm3 |

| Kukula kwa Thermal (RT-1200 ℃) | 4.5-6.5x10-6/k |

| Mtundu | Mchenga |

| PH | 6.6-7.3 |

| Mineralogical Composition | Soft + Corundum |

| Mtengo wa Acid | <1 ml/50g |

| LOI | <0.1% |

Ubwino

● Mchenga Wobiriwira. ZOtetezedwa ku chilengedwe poyerekeza ndi silika (silica) ndi mchenga wa zircon

● High refractoriness (>1800°C),can be used for casting various materials. There is also no need to use different sand type according to material.

● Mlingo wapamwamba wobwezeretsa. Onse Thermal ndi makina reclamation. Amapereka moyo wautali wogwira ntchito komanso kuchepetsa kugwiritsa ntchito mchenga.

● Kukomoka kwambiri. Mchenga wa Sintered Ceramic mawonekedwe ozungulira poyerekeza ndi njere zooneka ngati makona amalola kupatukana kosavuta ndi magawo opangidwa ndi zida zotayidwa komanso kugwa bwino zomwe zimapangitsa kuti zinyalala zotsika komanso kuponya bwino.

● Kuchuluka kwamadzimadzi komanso kudzaza bwino chifukwa chokhala ozungulira.

● Kukula kwapansi kwa Thermal ndi Thermal Conductivity. Kuponyera miyeso ndi yolondola kwambiri ndipo kutsika kwa conductivity kumapereka ntchito yabwino ya nkhungu.

● Kuchulukirachulukira kochepa. Monga mchenga wopangidwa ndi ceramic ndi pafupifupi theka lopepuka ngati mchenga wa ceramic wosakanikirana (mchenga wa mpira wakuda), zircon ndi chromite, ukhoza kuchulukitsa kuwirikiza kawiri kuchuluka kwa nkhungu pa kulemera kwa unit. Itha kuchitidwanso mosavuta, kupulumutsa ntchito ndi ndalama zosinthira mphamvu. Komabe, chidwi chiyenera kuperekedwa ku kuchuluka kwa binder kuwonjezera.

● Pamafunika 40-50% zochepa utomoni.

● Zojambulazo zimakutidwa ndi zokutira pang'ono kapena zosakhalapo.

● Angagwiritsidwe ntchito ngati mchenga umodzi.

● Zinthu zokhazikika. Kuthekera kwapachaka 200,000 MT kuti musunge mwachangu komanso mokhazikika.

Kugwiritsa ntchito

Monga zinthu zosalowerera ndale, mchenga wa ceramic wa KAIST umagwira ntchito ku utomoni wa asidi ndi alkali.

Itha kugwiritsidwa ntchito kwambiri popanga chitsulo choponyedwa, chitsulo choponyedwa ndi zitsulo zopanda chitsulo, monga kuponyera chithovu chotayika, mchenga wokutidwa, mchenga wa utomoni, bokosi lozizira pachimake, kuponyera mwatsatanetsatane, ndi kusindikiza kwa 3D.

Magawo a Particle size Distribution

The tinthu kukula kugawa akhoza makonda malinga ndi lamulo lanu.

|

Mesh |

20 | 30 | 40 | 50 | 70 | 100 | 140 | 200 | 270 | Pansi | AFS | |

|

μm |

850 | 600 | 425 | 300 | 212 | 150 | 106 | 75 | 53 | Pansi | ||

| Kodi | 20/40 | 15-40 | 30-55 | 15-35 | ≤5 | 20±5 | ||||||

| 30/50 | ≤1 | 25-35 | 35-50 | 15-25 | ≤10 | ≤1 | 30±5 | |||||

| 40/70 | ≤5 | 20-30 | 40-50 | 15-25 | ≤8 | ≤1 | 43±3 | |||||

| 70/40 | ≤5 | 15-25 | 40-50 | 20-30 | ≤10 | ≤2 | 46±3 | |||||

| 50/100 | ≤5 | 25-35 | 35-50 | 15-25 | ≤6 | ≤1 | 50±3 | |||||

| 100/50 | ≤5 | 15-25 | 35-50 | 25-35 | ≤10 | ≤1 | 55±3 | |||||

| 70/140 | ≤5 | 25-35 | 35-50 | 8-15 | ≤5 | ≤1 | 65±4 | |||||

| 140/70 | ≤5 | 15-35 | 35-50 | 20-25 | ≤8 | ≤2 | 70±5 | |||||

| 100/200 | ≤10 | 20-35 | 35-50 | 15-20 | ≤10 | ≤2 | 110±5 | |||||

Magulu azinthu