- African

- ChiAlbanian

- ChiAmharic

- ChiArabic

- ChiArmenian

- Azerbaijani

- ChiBasque

- Chiberaruzi

- ChiBengali

- ChiBosnian

- ChiBulgarian

- Katarani

- Cebuano

- China

- China (Taiwan)

- Kosikeni

- ChiCroatian

- ChiCzech

- ChiDanish

- ChiDutch

- Chirungu

- Esiperando

- ChiEstonian

- ChiFinish

- ChiFrench

- Frisian

- ChiGalician

- ChiGeorgian

- ChiJerimani

- ChiGiriki

- ChiGujarati

- Kiriyoro yeHaiti

- ChiHausa

- Chihawayi

- ChiHebhuru

- kwete

- Miao

- ChiHungarian

- ChiIcelandic

- igbo

- ChiIndonesian

- ChiIrish

- ChiItalian

- ChiJapanese

- ChiJavanese

- ChiKannada

- Kazaki

- Khmer

- Rwandan

- ChiKorean

- ChiKedhi

- Kiyagizi

- TB

- Ratini

- ChiLatvian

- Ritunia

- Rukusembogi

- ChiMacedonian

- Malgashi

- ChiMalay

- ChiMalayalam

- ChiMaltese

- Maori

- ChiMarati

- ChiMongoria

- Mayanima

- ChiNepali

- ChiNorwegian

- ChiNorwegian

- Occitan

- Pashito

- ChiPersian

- ChiPolish

- ChiPutukezi

- Punjabi

- ChiRomanian

- ChiRussian

- Samoan

- ChiGaelic cheScottish

- ChiSebhiya

- Chirungu

- Shona

- ChiSindhi

- Sinhala

- ChiSlovak

- ChiSlovanian

- Somari

- ChiSpanish

- Sundanese

- ChiSwahili

- ChiSwedish

- ChiTagalog

- Tajik

- ChiTamil

- Tatar

- ChiTelugu

- ChiThai

- Turkish

- ChiTeki

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Help

- Yiddish

- Yoruba

- Zulu

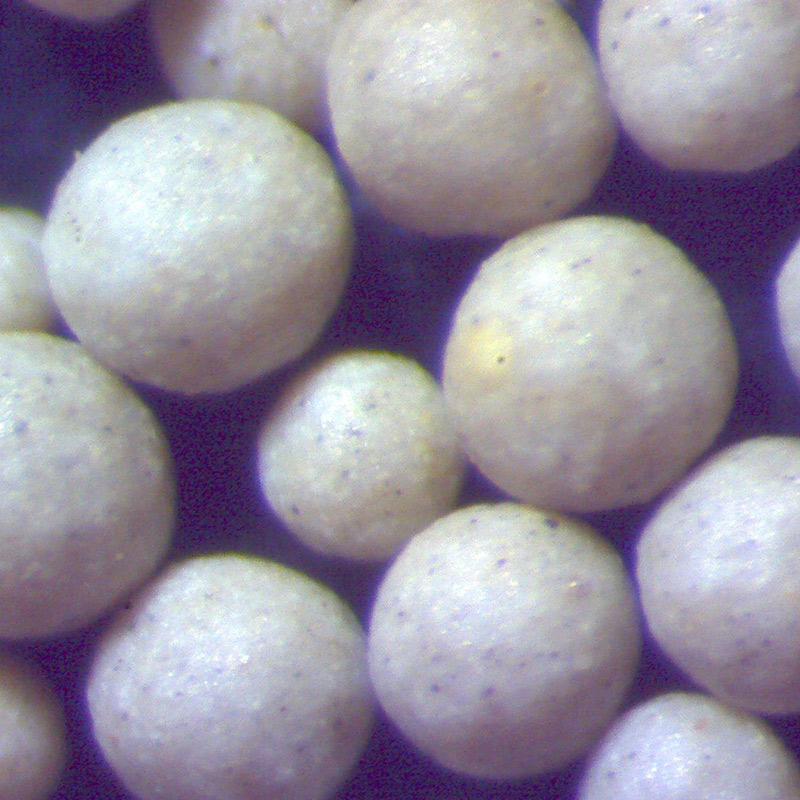

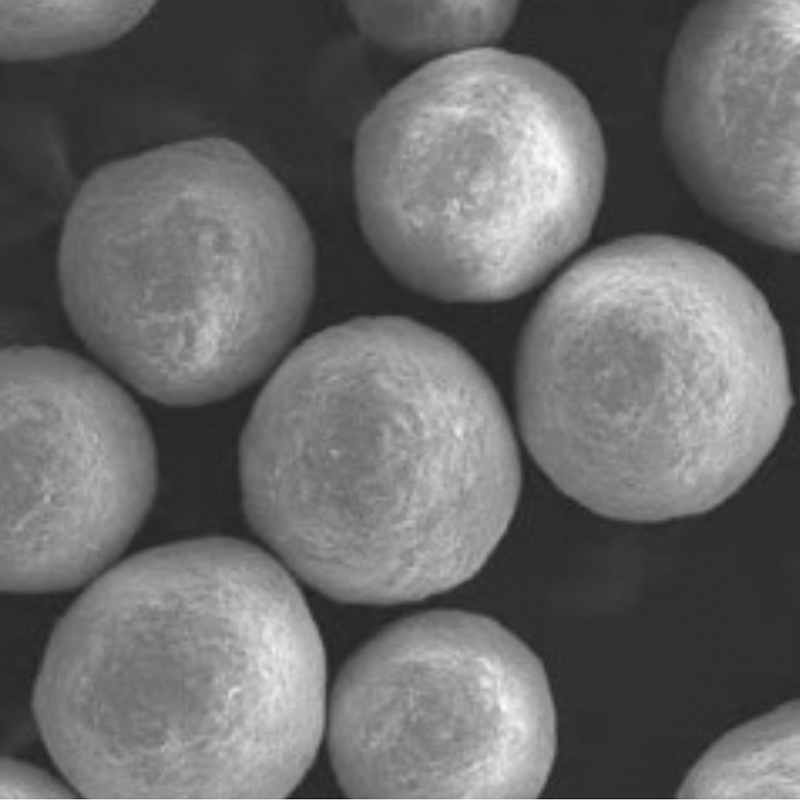

Spherical Ceramic Sand ye Foundry

Ceramic Sand Property

| Main Chemical Component | Al₂O₃≥53%, Fe₂O₃<4%, TiO₂<3%, SiO₂≤37% |

| Zviyo Chimiro | Spherical |

| Angular Coefficient | ≤1.1 |

| Chikamu Saizi | 45μm -2000μm |

| Refractoriness | ≥1800℃ |

| Bulk Density | 1.5-1.6 g/cm3 |

| Kuwedzera Kwekupisa (RT-1200℃) | 4.5-6.5x10-6/k |

| Color | Jecha |

| PH | 6.6-7.3 |

| Mineralogical Composition | Yakapfava + Corundum |

| Acid Cost | <1 ml/50g |

| LOI | <0.1% |

Advantage

● Green Sand. YAKANAKA kune zvakatipoteredza kana ichienzaniswa nesilica (silicosis) uye zircon jecha

● High refractoriness (>1800°C),can be used for casting various materials. There is also no need to use different sand type according to material.

● High reclamation rate. Zvese zviri zviviri Thermal uye mechanical reclamation. Inopa hupenyu hurefu hwebasa uye kuderedza kushandiswa kwejecha.

● High collapsibility. Sintered Ceramic sand spherical shape kana ichienzaniswa neangular shaped tsanga inobvumira kupatsanurwa kuri nyore kubva kuzvikamu zvakakandwa uye nekunatsiridza kudonha kunokonzeresa kuderera kwezvimedu uye kugona kukanda.

● Kuyerera kwakanakisa uye kushanda zvakanaka kwekuzadza nekuda kwekutenderera.

● Lower Thermal kuwedzera uye Thermal Conductivity. Zviyero zvekukanda zvakanyanya uye yakaderera conductivity inopa zvirinani mold kuita.

● Kuderera kwehuwandu hwakawanda. Sejecha receramic rekugadzira rinenge hafu yekureruka sejecha receramic rakasanganiswa (jecha dema rebhora), zircon uye chromite, rinogona kubuda zvakapetwa kaviri nhamba yezviumbwa pahuremu hweyuniti. Inogona zvakare kubatwa zviri nyore, kuchengetedza vashandi uye kutamisa simba mari. Nekudaro, kutariswa kunofanirwa kupihwa kune huwandu hwekuwedzera binder.

● Inoda 40-50% shoma resin.

● Matanda anonamira zvishoma kana kuti asina.

● Inogona kushandiswa sejecha rimwe chete.

● Kugovera kwakagadzikana. Kwegore kugona 200,000 MT kuchengetedza kukurumidza uye kugadzikana kwekupa.

Application

Sechinhu chisina kwazvakarerekera, KAIST ceramic jecha rinoshanda kune acid uye alkali resins.

Inogona kushandiswa zvakanyanya kugadzira simbi yakakandwa, simbi yakakandwa uye nonferrous simbi kukanda, seyakarasika furo kukanda, jecha rakavharidzirwa, jecha resin, bhokisi rinotonhora repakati, kukanda chaiko, uye kudhinda kwe3D.

Zvikamu zveParticle size Distribution

Iyo particle size yekugovera inogona kugadzirwa zvinoenderana nezvaunoda.

|

Mesh |

20 | 30 | 40 | 50 | 70 | 100 | 140 | 200 | 270 | Pan | AFS | |

|

μm |

850 | 600 | 425 | 300 | 212 | 150 | 106 | 75 | 53 | Pan | ||

| Code | 20/40 | 15-40 | 30-55 | 15-35 | ≤5 | 20±5 | ||||||

| 30/50 | ≤1 | 25-35 | 35-50 | 15-25 | ≤10 | ≤1 | 30±5 | |||||

| 40/70 | ≤5 | 20-30 | 40-50 | 15-25 | ≤8 | ≤1 | 43±3 | |||||

| 70/40 | ≤5 | 15-25 | 40-50 | 20-30 | ≤10 | ≤2 | 46±3 | |||||

| 50/100 | ≤5 | 25-35 | 35-50 | 15-25 | ≤6 | ≤1 | 50±3 | |||||

| 100/50 | ≤5 | 15-25 | 35-50 | 25-35 | ≤10 | ≤1 | 55±3 | |||||

| 70/140 | ≤5 | 25-35 | 35-50 | 8-15 | ≤5 | ≤1 | 65±4 | |||||

| 140/70 | ≤5 | 15-35 | 35-50 | 20-25 | ≤8 | ≤2 | 70±5 | |||||

| 100/200 | ≤10 | 20-35 | 35-50 | 15-20 | ≤10 | ≤2 | 110±5 | |||||

Zvigadzirwa zvikamu