- африканський

- албанець

- амхарська

- арабська

- вірменський

- Азербайджанська

- Баскська

- білоруська

- Бенгальська

- боснійський

- Болгарська

- каталонська

- Себуано

- Китай

- Китай (Тайвань)

- Корсиканець

- Хорватська

- чеська

- датська

- голландська

- англійська

- Есперанто

- Естонська

- фінська

- французька

- фризька

- Галицький

- грузинський

- Німецький

- грецька

- Гуджараті

- Гаїтянська креольська

- хауса

- гавайський

- іврит

- ні

- Мяо

- угорська

- ісландська

- ігбо

- індонезійська

- ірландський

- італійська

- Японський

- яванський

- каннада

- казахська

- кхмерська

- Руанда

- корейська

- курдська

- киргизький

- туберкульоз

- латинь

- латиська

- литовський

- люксембурзький

- македонська

- Малгаші

- малайська

- малаялам

- мальтійська

- Маорі

- маратхі

- монгольська

- М'янма

- непальська

- норвезька

- норвезька

- Окситанська

- пушту

- перська

- польський

- португальська

- Пенджабі

- румунська

- російський

- Самоанська

- Шотландська гельська

- сербська

- англійська

- Шона

- Сіндхі

- сингальська

- словацький

- словенська

- сомалі

- Іспанська

- Сунданська

- Суахілі

- шведська

- тагальська

- таджицька

- тамільська

- татарський

- Телугу

- тайська

- турецька

- туркменський

- українська

- урду

- уйгурський

- узбецький

- в'єтнамська

- Валлійська

- Довідка

- ідиш

- йоруба

- Зулу

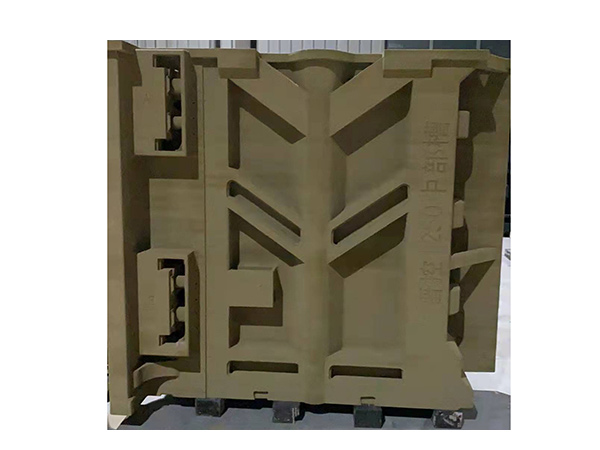

Куля з піску Ceramcast для лиття в пісок

| Основний хімічний компонент | Al₂O₃≥53%, Fe₂O₃<4%, TiO₂<3%, SiO₂≤37% |

| Форма зерна | Сферичний |

| Кутовий коефіцієнт | ≤1,1 |

| Розмір частки | 45 мкм -2000 мкм |

| Тугоплавкість | ≥1800 ℃ |

| Об'ємна щільність | 1,45-1,6 г/см3 |

| Теплове розширення (RT-1200 ℃) | 4,5-6,5х10-6/к |

| Колір | Пісок |

| PH | 6.6-7.3 |

| Мінералогічний склад | М'який + Корунд |

| Вартість кислоти | <1 мл/50г |

| LOI | <0,1% |

Перевага

● Uniform component composition

● Higher refractoriness≥1800℃. In special casting conditions with higher temperature, it can provide better adaptability and lower the ratio of defects such as sand burning-on, sintering, and veining;

● Low thermal expansion coefficient. It can greatly lower the defects and improve the size accuracy of cast products.

● Lower angular coefficient<1.1. Ceramcast ball shape can effectively improve the breathability and surface accuracy of cast products.

● Lower bulk density(1.45-1.6g/cm3). Ceramcast bulk density is similar with silica sand’s, If the weights are the same, KAIST ceramic sand can produce additional 25% sand core compared with fused ceramic sand to lower the procurement cost.

● The stable product properties and uniform colors can guarantee high quality supply.

● a neutral material, KAIST ceramic sand is applicable to acid and alkali resins.

● Higher renewable recycling characteristics. The recycling rate can reach 98%, it can reduce your purchase cost, and reduce the enterprise solid waste discharge to the maximum extent, keep the workshops are dust-free, green, and environment-friendly.

застосування

Ceramcast can be used for all types of sand castings, now we have successfully applicated to Resin-coated sand, Cold box sand, green sand, 3D sand printing, lost foam casting, No-baked sand, etc, steel castings, iron castings, alloy castings, aluminum casting, copper castings, etc. high-end sand casting. Kaist Ceramcast have excellent reclamation property, it can be used in mechanical and thermal reclamation ways, lower waste sand discharge, offer you a green foundry factory.

Частини Розподіл частинок за розміром

Розподіл частинок за розміром можна налаштувати відповідно до ваших вимог.

|

Сітка |

20 | 30 | 40 | 50 | 70 | 100 | 140 | 200 | 270 | Пан | AFS | |

|

мкм |

850 | 600 | 425 | 300 | 212 | 150 | 106 | 75 | 53 | Пан | ||

| Код | 20/40 | 15-40 | 30-55 | 15-35 | ≤5 | 20±5 | ||||||

| 30/50 | ≤1 | 25-35 | 35-50 | 15-25 | ≤10 | ≤1 | 30±5 | |||||

| 40/70 | ≤5 | 20-30 | 40-50 | 15-25 | ≤8 | ≤1 | 43±3 | |||||

| 70/40 | ≤5 | 15-25 | 40-50 | 20-30 | ≤10 | ≤2 | 46±3 | |||||

| 50/100 | ≤5 | 25-35 | 35-50 | 15-25 | ≤6 | ≤1 | 50±3 | |||||

| 100/50 | ≤5 | 15-25 | 35-50 | 25-35 | ≤10 | ≤1 | 55±3 | |||||

| 70/140 | ≤5 | 25-35 | 35-50 | 8-15 | ≤5 | ≤1 | 65±4 | |||||

| 140/70 | ≤5 | 15-35 | 35-50 | 20-25 | ≤8 | ≤2 | 70±5 | |||||

| 100/200 | ≤10 | 20-35 | 35-50 | 15-20 | ≤10 | ≤2 | 110±5 | |||||

Категорії товарів