- africano

- albanés

- amárico

- árabe

- armenio

- azerbaiyano

- vasco

- bielorruso

- bengalí

- bosníaco

- búlgaro

- catalán

- Cebuano

- China

- China (Taiwán)

- corso

- croata

- checo

- danés

- holandés

- inglés

- Esperanto

- Estonio

- finés

- francés

- frisón

- galego

- xeorxiano

- alemán

- grego

- Gujarati

- crioulo haitiano

- hausa

- hawaiano

- hebreo

- non

- Miao

- húngaro

- islandés

- igbo

- indonesio

- irlandesa

- italiano

- xaponés

- xavanés

- Kannada

- casco

- Khmer

- Ruandés

- coreano

- kurdo

- Kirguiz

- TB

- latín

- letón

- lituano

- luxemburgués

- macedonio

- Malgashi

- malaio

- Malayalam

- maltés

- maorí

- Marathi

- mongol

- Myanmar

- nepalí

- noruegués

- noruegués

- occitano

- Pashto

- persa

- polaco

- portugués

- Punjabi

- romanés

- ruso

- samoano

- Gaélico escocés

- serbio

- inglés

- Shona

- Sindhi

- cingalés

- eslovaco

- esloveno

- somalí

- castelán

- sundanés

- suahili

- sueco

- Tagalo

- taxico

- Tamil

- tártaro

- Telugu

- tailandés

- turco

- turcomano

- ucraíno

- Urdú

- uigur

- uzbeco

- vietnamita

- galés

- Axuda

- yiddish

- ioruba

- Zulú

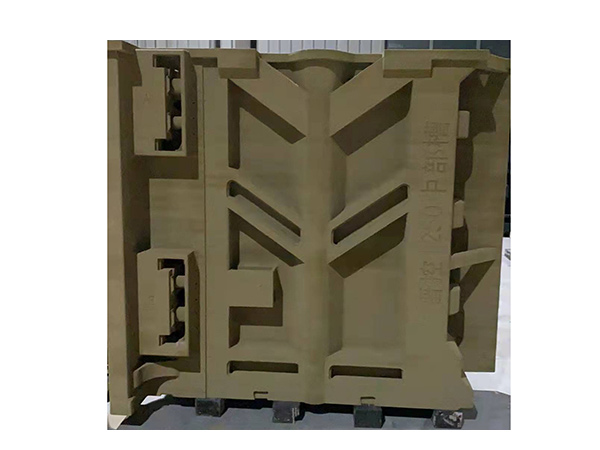

Forma de bola de area Ceramcast para fundición en area

| Compoñente químico principal | Al₂O₃≥53%, Fe₂O₃<4%, TiO₂<3%, SiO₂≤37% |

| Forma de gran | Esférico |

| Coeficiente angular | ≤1,1 |

| Tamaño de partícula | 45 μm - 2000 μm |

| Refractariedade | ≥1800℃ |

| Densidade a granel | 1,45-1,6 g/cm3 |

| Expansión térmica (RT-1200 ℃) | 4,5-6,5x10-6/k |

| Cor | Area |

| PH | 6.6-7.3 |

| Composición Mineralóxica | Suave + Corindón |

| Custo do ácido | <1 ml/50 g |

| LOI | <0,1% |

Vantaxe

● Uniform component composition

● Higher refractoriness≥1800℃. In special casting conditions with higher temperature, it can provide better adaptability and lower the ratio of defects such as sand burning-on, sintering, and veining;

● Low thermal expansion coefficient. It can greatly lower the defects and improve the size accuracy of cast products.

● Lower angular coefficient<1.1. Ceramcast ball shape can effectively improve the breathability and surface accuracy of cast products.

● Lower bulk density(1.45-1.6g/cm3). Ceramcast bulk density is similar with silica sand’s, If the weights are the same, KAIST ceramic sand can produce additional 25% sand core compared with fused ceramic sand to lower the procurement cost.

● The stable product properties and uniform colors can guarantee high quality supply.

● a neutral material, KAIST ceramic sand is applicable to acid and alkali resins.

● Higher renewable recycling characteristics. The recycling rate can reach 98%, it can reduce your purchase cost, and reduce the enterprise solid waste discharge to the maximum extent, keep the workshops are dust-free, green, and environment-friendly.

Aplicación

Ceramcast can be used for all types of sand castings, now we have successfully applicated to Resin-coated sand, Cold box sand, green sand, 3D sand printing, lost foam casting, No-baked sand, etc, steel castings, iron castings, alloy castings, aluminum casting, copper castings, etc. high-end sand casting. Kaist Ceramcast have excellent reclamation property, it can be used in mechanical and thermal reclamation ways, lower waste sand discharge, offer you a green foundry factory.

Partes da distribución do tamaño das partículas

A distribución do tamaño das partículas pódese personalizar segundo as súas necesidades.

|

Malla |

20 | 30 | 40 | 50 | 70 | 100 | 140 | 200 | 270 | Pan | AFS | |

|

μm |

850 | 600 | 425 | 300 | 212 | 150 | 106 | 75 | 53 | Pan | ||

| Código | 20/40 | 15-40 | 30-55 | 15-35 | ≤5 | 20 ± 5 | ||||||

| 30/50 | ≤1 | 25-35 | 35-50 | 15-25 | ≤10 | ≤1 | 30 ± 5 | |||||

| 40/70 | ≤5 | 20-30 | 40-50 | 15-25 | ≤8 | ≤1 | 43 ± 3 | |||||

| 70/40 | ≤5 | 15-25 | 40-50 | 20-30 | ≤10 | ≤2 | 46 ± 3 | |||||

| 50/100 | ≤5 | 25-35 | 35-50 | 15-25 | ≤6 | ≤1 | 50 ± 3 | |||||

| 100/50 | ≤5 | 15-25 | 35-50 | 25-35 | ≤10 | ≤1 | 55 ± 3 | |||||

| 70/140 | ≤5 | 25-35 | 35-50 | 8-15 | ≤5 | ≤1 | 65 ± 4 | |||||

| 140/70 | ≤5 | 15-35 | 35-50 | 20-25 | ≤8 | ≤2 | 70 ± 5 | |||||

| 100/200 | ≤10 | 20-35 | 35-50 | 15-20 | ≤10 | ≤2 | 110 ± 5 | |||||

Categorías de produtos