- अफ्रिकी

- अल्बेनियन्

- अम्हारिक

- अरबी

- आर्मेनियाली

- अजरबैजानी

- बास्क

- बेलारूसी

- बंगाली

- बोस्नियाली

- बुल्गेरियन

- क्याटालान

- सेबुआनो

- चीन

- चीन (ताइवान)

- कोर्सिकन

- क्रोएसियाली

- चेक

- डेनिस

- डच

- अंग्रेजी

- एस्पेरान्तो

- इस्टोनियाली

- फिनिस

- फ्रान्सेली

- फ्रिसियन

- ग्यालिसियन

- जर्जियाली

- जर्मन

- ग्रीक

- गुजराती

- हाइटियन क्रियोल

- हौसा

- हवाईयन

- हिब्रू

- होइन

- मियाओ

- हंगेरी

- आइसल्याण्डिक

- igbo

- इन्डोनेसियाली

- आइरिस

- इटालियन

- जापानी

- जाभानीज

- कन्नड

- कजाख

- खमेर

- रुवाण्डन

- कोरियाली

- कुर्दिश

- किर्गिज

- TB

- ल्याटिन

- लाटभियन

- लिथुआनियाली

- लक्जमबर्गिश

- म्यासेडोनियन

- मालगाशी

- मलय

- मलयालम

- माल्टीज

- माओरी

- मराठी

- मङ्गोलियन

- म्यानमार

- नेपाली

- नर्वेजियन

- नर्वेजियन

- अक्सिटन

- पश्तो

- फारसी

- पोलिश

- पोर्चुगिज

- पञ्जाबी

- रोमानियाली

- रुसी

- सामोन

- स्कटिश गेलिक

- सर्बियाई

- अंग्रेजी

- शोना

- सिन्धी

- सिंहला

- स्लोभाक

- स्लोभेनियाली

- सोमाली

- स्पेनिस

- सुन्दानीज

- स्वाहिली

- स्विडेनी

- तागालोग

- ताजिक

- तमिल

- टाटर

- तेलुगु

- थाई

- टर्की

- तुर्कमेन

- युक्रेनी

- उर्दू

- उइघुर

- उज्बेक

- भियतनामी

- वेल्श

- मद्दत गर्नुहोस्

- येडिस

- योरुबा

- जुलु

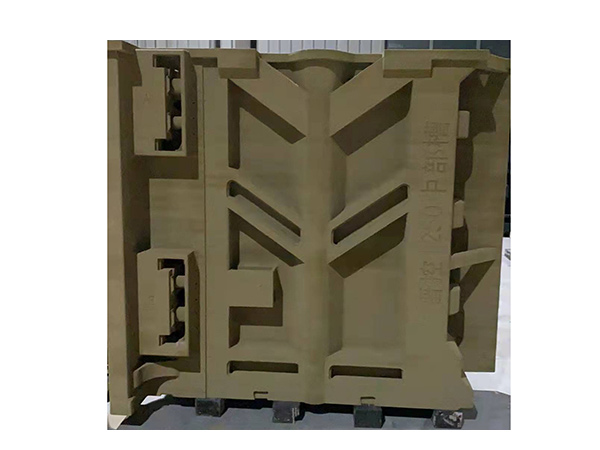

बालुवा कास्टिङको लागि Ceramcast बालुवा बल आकार

| मुख्य रासायनिक घटक | Al₂O₃≥53%, Fe₂O₃4%, TiO₂3%, SiO₂≤37% |

| अनाज आकार | गोलाकार |

| कोणीय गुणांक | ≤१.१ |

| कण आकार | 45μm -2000μm |

| अपवर्तकता | ≥1800℃ |

| बल्क घनत्व | 1.45-1.6 g/cm3 |

| थर्मल विस्तार (RT-1200℃) | ४.५-६.५x१०-६/के |

| रङ | बालुवा |

| PH | 6.6-7.3 |

| खनिज संरचना | नरम + कोरन्डम |

| एसिड लागत | 1 एमएल / 50 ग्राम |

| LOI | ~ ०.१% |

फाइदा

● Uniform component composition

● Higher refractoriness≥1800℃. In special casting conditions with higher temperature, it can provide better adaptability and lower the ratio of defects such as sand burning-on, sintering, and veining;

● Low thermal expansion coefficient. It can greatly lower the defects and improve the size accuracy of cast products.

● Lower angular coefficient<1.1. Ceramcast ball shape can effectively improve the breathability and surface accuracy of cast products.

● Lower bulk density(1.45-1.6g/cm3). Ceramcast bulk density is similar with silica sand’s, If the weights are the same, KAIST ceramic sand can produce additional 25% sand core compared with fused ceramic sand to lower the procurement cost.

● The stable product properties and uniform colors can guarantee high quality supply.

● a neutral material, KAIST ceramic sand is applicable to acid and alkali resins.

● Higher renewable recycling characteristics. The recycling rate can reach 98%, it can reduce your purchase cost, and reduce the enterprise solid waste discharge to the maximum extent, keep the workshops are dust-free, green, and environment-friendly.

आवेदन

Ceramcast can be used for all types of sand castings, now we have successfully applicated to Resin-coated sand, Cold box sand, green sand, 3D sand printing, lost foam casting, No-baked sand, etc, steel castings, iron castings, alloy castings, aluminum casting, copper castings, etc. high-end sand casting. Kaist Ceramcast have excellent reclamation property, it can be used in mechanical and thermal reclamation ways, lower waste sand discharge, offer you a green foundry factory.

कण आकार वितरण को भागहरु

कण आकार वितरण आफ्नो आवश्यकता अनुसार अनुकूलित गर्न सकिन्छ.

|

जाल |

20 | 30 | 40 | 50 | 70 | 100 | 140 | 200 | 270 | प्यान | AFS | |

|

μm |

850 | 600 | 425 | 300 | 212 | 150 | 106 | 75 | 53 | प्यान | ||

| कोड | 20/40 | 15-40 | 30-55 | 15-35 | ≤५ | २०±५ | ||||||

| 30/50 | ≤१ | 25-35 | 35-50 | 15-25 | ≤१० | ≤१ | ३०±५ | |||||

| 40/70 | ≤५ | 20-30 | 40-50 | 15-25 | ≤८ | ≤१ | ४३±३ | |||||

| 70/40 | ≤५ | 15-25 | 40-50 | 20-30 | ≤१० | ≤२ | ४६±३ | |||||

| 50/100 | ≤५ | 25-35 | 35-50 | 15-25 | ≤६ | ≤१ | ५०±३ | |||||

| 100/50 | ≤५ | 15-25 | 35-50 | 25-35 | ≤१० | ≤१ | ५५±३ | |||||

| 70/140 | ≤५ | 25-35 | 35-50 | 8-15 | ≤५ | ≤१ | ६५±४ | |||||

| 140/70 | ≤५ | 15-35 | 35-50 | 20-25 | ≤८ | ≤२ | ७०±५ | |||||

| 100/200 | ≤१० | 20-35 | 35-50 | 15-20 | ≤१० | ≤२ | ११०±५ | |||||

उत्पादन कोटिहरु