- Neeg African

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Tuam Tshoj

- Tuam Tshoj (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Lus Askiv

- Esperanto

- Estonian

- Finnish

- Fabkis

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- haus

- hawaiian

- Hebrew

- Tsis yog

- Miao

- Hungarian

- Icelandic

- ib igbo

- Indonesian

- irish

- Italian

- Nyiv

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandan

- Kauslim

- Kurdish

- Kyrgyz

- TB

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Lavxias

- Samoan

- Scottish Gaelic

- Serbian

- Lus Askiv

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thaib

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Nyab Laj

- Welsh

- Pab

- Yiddish

- Yoruba

- Zulu

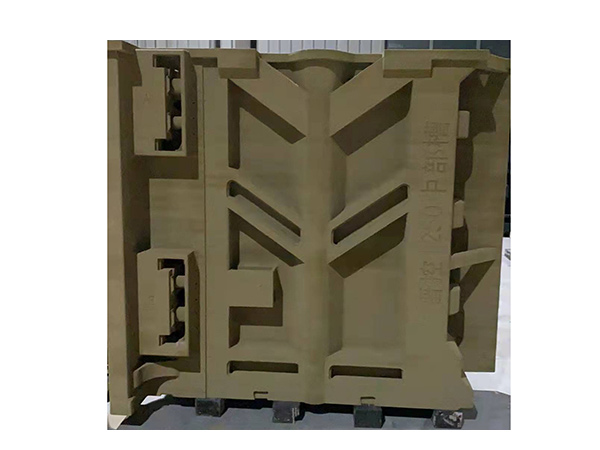

Ceramic xuab zeb pob zoo rau cov xuab zeb casting

| Main Chemical Component | Al₂O₃≥53%, Fe₂O₃<4%, TiO₂<3%, SiO₂≤37% |

| Grain Shape | kheej kheej |

| Angular Coefficient | ≤1.1 |

| Particle Loj | 45μm-2000μm |

| Refractoriness | ≥1800 ℃ |

| Kev ceev ceev | 1.45-1.6 g / cm3 |

| Thermal Expansion (RT-1200 ℃) | 4.5-6.5x10-6/k |

| Xim | Xuab zeb |

| PH | 6.6-7.3 |

| Mineralogical Composition | Mos + Corundum |

| Acid Nqi | 1 ml / 50g |

| LOI | ± 0.1% |

Qhov zoo

● Uniform component composition

● Higher refractoriness≥1800℃. In special casting conditions with higher temperature, it can provide better adaptability and lower the ratio of defects such as sand burning-on, sintering, and veining;

● Low thermal expansion coefficient. It can greatly lower the defects and improve the size accuracy of cast products.

● Lower angular coefficient<1.1. Ceramcast ball shape can effectively improve the breathability and surface accuracy of cast products.

● Lower bulk density(1.45-1.6g/cm3). Ceramcast bulk density is similar with silica sand’s, If the weights are the same, KAIST ceramic sand can produce additional 25% sand core compared with fused ceramic sand to lower the procurement cost.

● The stable product properties and uniform colors can guarantee high quality supply.

● a neutral material, KAIST ceramic sand is applicable to acid and alkali resins.

● Higher renewable recycling characteristics. The recycling rate can reach 98%, it can reduce your purchase cost, and reduce the enterprise solid waste discharge to the maximum extent, keep the workshops are dust-free, green, and environment-friendly.

Daim ntawv thov

Ceramcast can be used for all types of sand castings, now we have successfully applicated to Resin-coated sand, Cold box sand, green sand, 3D sand printing, lost foam casting, No-baked sand, etc, steel castings, iron castings, alloy castings, aluminum casting, copper castings, etc. high-end sand casting. Kaist Ceramcast have excellent reclamation property, it can be used in mechanical and thermal reclamation ways, lower waste sand discharge, offer you a green foundry factory.

Parts ntawm Particle loj Distribution

Lub particle loj tis tuaj yeem kho raws li koj xav tau.

|

Mesh |

20 | 30 | 40 | 50 | 70 | 100 | 140 | 200 | 270 | Pan | AFS | |

|

ib m |

850 | 600 | 425 | 300 | 212 | 150 | 106 | 75 | 53 | Pan | ||

| Code | 20/40 | 15-40 | 30-55 | 15-35 | ≤ 5 | 20 ± 5 | ||||||

| 30/50 | ≤1 | 25-35 | 35-50 | 15-25 | ≤10 | ≤1 | 30 ± 5 | |||||

| 40/70 | ≤ 5 | 20-30 | 40-50 | 15-25 | ≤ 8 | ≤1 | 43 ± 3 | |||||

| 70/40 | ≤ 5 | 15-25 | 40-50 | 20-30 | ≤10 | ≤ 2 | 46 ± 3 | |||||

| 50/100 | ≤ 5 | 25-35 | 35-50 | 15-25 | ≤ 6 | ≤1 | 50 ± 3 | |||||

| 100/50 | ≤ 5 | 15-25 | 35-50 | 25-35 | ≤10 | ≤1 | 55 ± 3 | |||||

| 70/140 | ≤ 5 | 25-35 | 35-50 | 8-15 | ≤ 5 | ≤1 | 65 ± 4 | |||||

| 140/70 | ≤ 5 | 15-35 | 35-50 | 20-25 | ≤ 8 | ≤ 2 | 70 ± 5 | |||||

| 100/200 | ≤10 | 20-35 | 35-50 | 15-20 | ≤10 | ≤ 2 | 110 ± 5 | |||||

Cov khoom qeb