- африкански

- албански

- амхарски

- арабски

- арменски

- азербайджански

- баски

- белоруски

- бенгалски

- босненски

- български

- каталонски

- себуано

- Китай

- Китай (Тайван)

- корсикански

- хърватски

- чешки

- датски

- холандски

- Английски

- Есперанто

- естонски

- финландски

- Френски

- фризийски

- галисийски

- грузински

- Немски

- Гръцки

- гуджарати

- хаитянски креолски

- хауса

- хавайски

- иврит

- не

- Мяо

- унгарски

- исландски

- игбо

- индонезийски

- ирландски

- Италиански

- японски

- явански

- каннада

- казахски

- кхмерски

- Руанда

- корейски

- кюрдски

- киргизки

- туберкулоза

- латински

- латвийски

- литовски

- люксембургски

- македонски

- Малгаши

- малайски

- малаялам

- малтийски

- маори

- маратхи

- монголски

- Мианмар

- непалски

- норвежки

- норвежки

- окситански

- Pashto

- персийски

- полски

- португалски

- пенджабски

- румънски

- Руски

- самоански

- шотландски келтски

- сръбски

- Английски

- Шона

- Синдхи

- сингалски

- словашки

- словенски

- сомалийски

- испански

- сундански

- суахили

- шведски

- тагалог

- таджикски

- тамилски

- татарски

- телугу

- тайландски

- Турски

- туркменски

- украински

- урду

- уйгурски

- узбекски

- виетнамски

- уелски

- Помогне

- идиш

- йоруба

- зулу

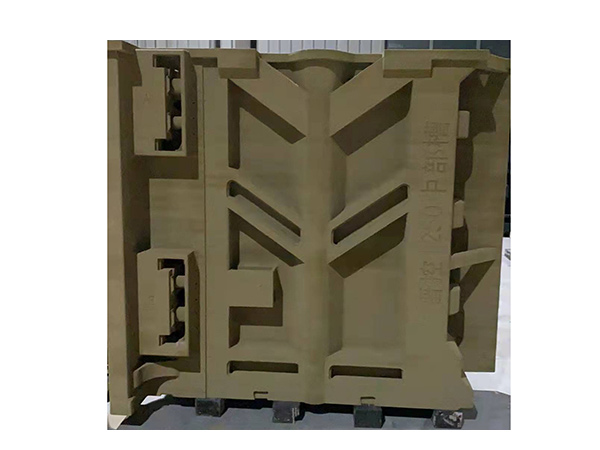

Форма на пясъчна топка Ceramcast за леене в пясък

| Основен химичен компонент | Al₂O₃≥53%, Fe₂O₃<4%, TiO₂<3%, SiO₂≤37% |

| Форма на зърно | Сферични |

| Ъглов коефициент | ≤1,1 |

| Размер на частиците | 45μm -2000μm |

| Огнеупорност | ≥1800 ℃ |

| Обемна плътност | 1,45-1,6 g/cm3 |

| Термично разширение(RT-1200℃) | 4,5-6,5х10-6/к |

| Цвят | Пясък |

| PH | 6.6-7.3 |

| Минералогичен състав | Мек + Корунд |

| Acid Cost | <1 ml/50g |

| LOI | <0,1% |

Предимство

● Uniform component composition

● Higher refractoriness≥1800℃. In special casting conditions with higher temperature, it can provide better adaptability and lower the ratio of defects such as sand burning-on, sintering, and veining;

● Low thermal expansion coefficient. It can greatly lower the defects and improve the size accuracy of cast products.

● Lower angular coefficient<1.1. Ceramcast ball shape can effectively improve the breathability and surface accuracy of cast products.

● Lower bulk density(1.45-1.6g/cm3). Ceramcast bulk density is similar with silica sand’s, If the weights are the same, KAIST ceramic sand can produce additional 25% sand core compared with fused ceramic sand to lower the procurement cost.

● The stable product properties and uniform colors can guarantee high quality supply.

● a neutral material, KAIST ceramic sand is applicable to acid and alkali resins.

● Higher renewable recycling characteristics. The recycling rate can reach 98%, it can reduce your purchase cost, and reduce the enterprise solid waste discharge to the maximum extent, keep the workshops are dust-free, green, and environment-friendly.

Приложение

Ceramcast can be used for all types of sand castings, now we have successfully applicated to Resin-coated sand, Cold box sand, green sand, 3D sand printing, lost foam casting, No-baked sand, etc, steel castings, iron castings, alloy castings, aluminum casting, copper castings, etc. high-end sand casting. Kaist Ceramcast have excellent reclamation property, it can be used in mechanical and thermal reclamation ways, lower waste sand discharge, offer you a green foundry factory.

Части от Разпределение на размера на частиците

Разпределението на размера на частиците може да бъде персонализирано според вашите изисквания.

|

Мрежа |

20 | 30 | 40 | 50 | 70 | 100 | 140 | 200 | 270 | Пан | AFS | |

|

μm |

850 | 600 | 425 | 300 | 212 | 150 | 106 | 75 | 53 | Пан | ||

| Код | 20/40 | 15-40 | 30-55 | 15-35 | ≤5 | 20±5 | ||||||

| 30/50 | ≤1 | 25-35 | 35-50 | 15-25 | ≤10 | ≤1 | 30±5 | |||||

| 40/70 | ≤5 | 20-30 | 40-50 | 15-25 | ≤8 | ≤1 | 43±3 | |||||

| 70/40 | ≤5 | 15-25 | 40-50 | 20-30 | ≤10 | ≤2 | 46±3 | |||||

| 50/100 | ≤5 | 25-35 | 35-50 | 15-25 | ≤6 | ≤1 | 50±3 | |||||

| 100/50 | ≤5 | 15-25 | 35-50 | 25-35 | ≤10 | ≤1 | 55±3 | |||||

| 70/140 | ≤5 | 25-35 | 35-50 | 8-15 | ≤5 | ≤1 | 65±4 | |||||

| 140/70 | ≤5 | 15-35 | 35-50 | 20-25 | ≤8 | ≤2 | 70±5 | |||||

| 100/200 | ≤10 | 20-35 | 35-50 | 15-20 | ≤10 | ≤2 | 110±5 | |||||

Категории продукти