Ceramsite sand is an artificial spherical casting sand developed by SHXK, same with Japanese Cerabeads. It has high refractoriness (>1800°C), small angular coefficient (<1.1, approximately spherical), low acid consumption (neutral material), low binder content (at least 30% reduction in binder content), and particles high strength, non-breaking and other excellent characteristics, suitable for all types of sand foundry, especially for the coated sand. There are more successful application cases.

采用全陶粒砂制成覆膜砂,经再生后多次重复使用,可有效提高铸件质量和生产效率,降低铸件报废率,降低企业生产成本,长期使用成本比硅砂低。因此,近年来,几乎所有大型覆膜砂厂都已采用陶粒砂作为原砂生产覆膜砂。

优势

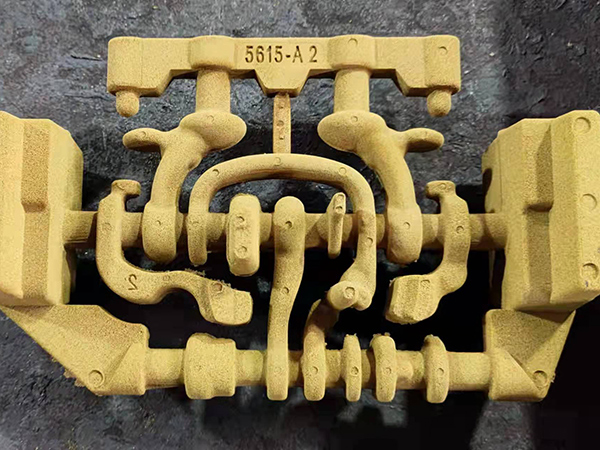

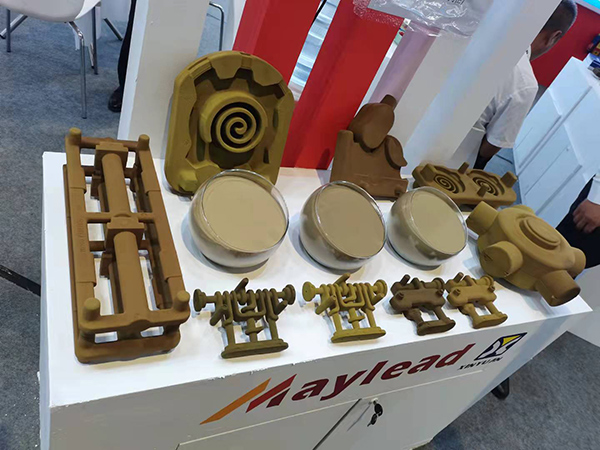

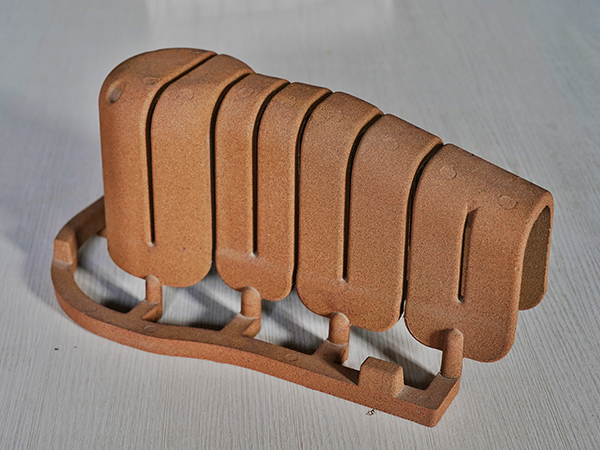

● 覆膜陶瓷砂具有超强的耐高温、抗变形强度高、低膨胀、低发气量等特点,可以满足客户的特殊要求。

● 流动性好,填充性好,不粘模,适用于人工制芯工艺。

● 超强的耐高温性能,可避免铸件产生烧砂、表面折叠、脉纹、接缝飞边、裂纹等缺陷。

● Small than 100kg castings could be achieved without sand coating.

粒度分布部分

粒度分布可根据您的要求定制.

|

网 |

20 | 30 | 40 | 50 | 70 | 100 | 140 | 200 | 270 | 平底锅 | 先进先出系统 | |

|

微米 |

850 | 600 | 425 | 300 | 212 | 150 | 106 | 75 | 53 | 平底锅 | ||

| 代码 | 40/70 | ≤5 | 20-30 | 40-50 | 15-25 | ≤8 | ≤1 | 43±3 | ||||

| 70/40 | ≤5 | 15-25 | 40-50 | 20-30 | ≤10 | ≤2 | 46±3 | |||||

| 50/100 | ≤5 | 25-35 | 35-50 | 15-25 | ≤6 | ≤1 | 50±3 | |||||

| 100/50 | ≤5 | 15-25 | 35-50 | 25-35 | ≤10 | ≤1 | 55±3 | |||||

| 70/140 | ≤5 | 25-35 | 35-50 | 8-15 | ≤5 | ≤1 | 65±4 | |||||

| 140/70 | ≤5 | 15-35 | 35-50 | 20-25 | ≤8 | ≤2 | 70±5 | |||||

| 100/200 | ≤10 | 20-35 | 35-50 | 15-20 | ≤10 | ≤2 | 110±5 | |||||

应用

发动机缸体、缸盖、活塞环、油封、地板弹簧。

中小型不锈钢、铸钢壳、离芯。

Used in large turbine shell mold, 6-8 speed gearbox, main part of auto brake disc,.

多缸机体(空翻式芯)、排气管、支气管。

凸轮轴、油封、箱角壳。

各类高标准、高要求、工艺难度较大的覆膜砂铸件。

Post time: Dec-30-2021

This is the last article