Ceramsite sand is an artificial spherical casting sand developed by SHXK, same with Japanese Cerabeads. It has high refractoriness (>1800°C), small angular coefficient (<1.1, approximately spherical), low acid consumption (neutral material), low binder content (at least 30% reduction in binder content), and particles high strength, non-breaking and other excellent characteristics, suitable for all types of sand foundry, especially for the coated sand. There are more successful application cases.

To'liq keramik qum qoplangan qumni tayyorlash uchun ishlatiladi va melioratsiyadan keyin qayta-qayta ishlatiladi, bu quymalarning sifati va ishlab chiqarish samaradorligini samarali oshirishi, to'qimalarning qirqish tezligini va korxonalarning ishlab chiqarish xarajatlarini kamaytirishi mumkin, uzoq muddatli foydalanish narxi undan past. silika qumidan. Shu sababli, so'nggi yillarda deyarli barcha yirik qoplamali qum zavodlari qoplangan qum ishlab chiqarish uchun xom qum sifatida keramik qumdan foydalangan.

Afzallik

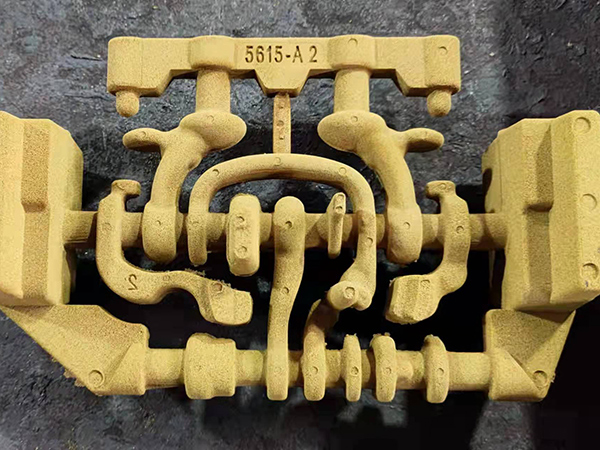

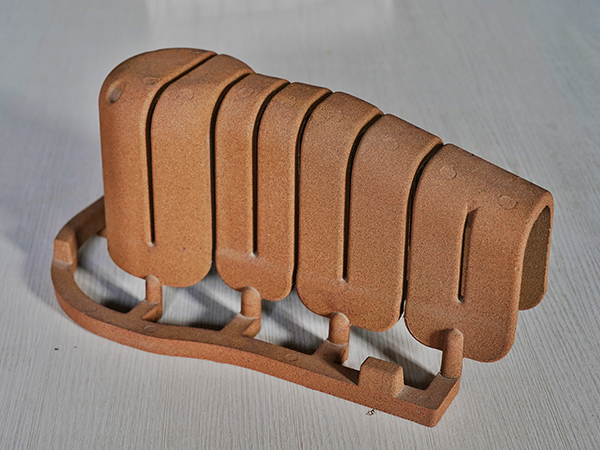

● Mijozlarning maxsus talablarini qondirish uchun super yuqori haroratga chidamlilik, deformatsiya intensivligiga kuchli qarshilik, past inflyatsiya, past gaz evolyutsiyasi bilan qatron bilan qoplangan keramik qum.

● Yaxshi suyuqlikni to'ldirish qobiliyati, yopishmaydigan qolip, sun'iy yadro yaratish jarayoni uchun qo'llaniladi.

● Yuqori haroratga chidamlilik qumning yonishi, sirt burmalari, tomirlar, bo'g'inlar chirog'i va yorilish kabi quyma nuqsonlardan qochishi mumkin.

● Small than 100kg castings could be achieved without sand coating.

Zarrachalar hajmining taqsimoti qismlari

Zarrachalar hajmini taqsimlash sizning talabingizga muvofiq sozlanishi mumkin.

|

Mesh |

20 | 30 | 40 | 50 | 70 | 100 | 140 | 200 | 270 | Pan | AFS | |

|

mkm |

850 | 600 | 425 | 300 | 212 | 150 | 106 | 75 | 53 | Pan | ||

| kod | 40/70 | ≤5 | 20-30 | 40-50 | 15-25 | ≤8 | ≤1 | 43±3 | ||||

| 70/40 | ≤5 | 15-25 | 40-50 | 20-30 | ≤10 | ≤2 | 46±3 | |||||

| 50/100 | ≤5 | 25-35 | 35-50 | 15-25 | ≤6 | ≤1 | 50±3 | |||||

| 100/50 | ≤5 | 15-25 | 35-50 | 25-35 | ≤10 | ≤1 | 55±3 | |||||

| 70/140 | ≤5 | 25-35 | 35-50 | 8-15 | ≤5 | ≤1 | 65±4 | |||||

| 140/70 | ≤5 | 15-35 | 35-50 | 20-25 | ≤8 | ≤2 | 70±5 | |||||

| 100/200 | ≤10 | 20-35 | 35-50 | 15-20 | ≤10 | ≤2 | 110±5 | |||||

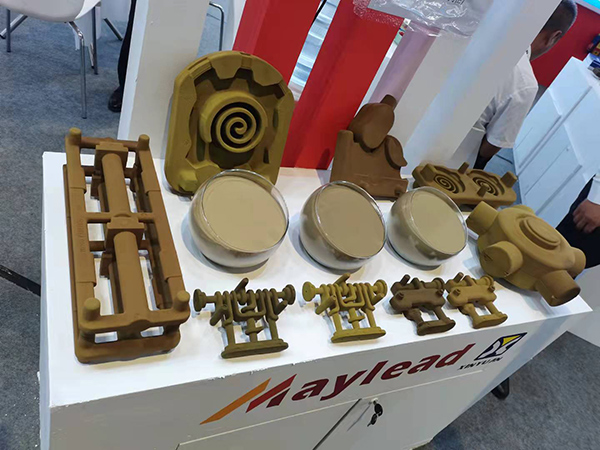

Ilova

Dvigatel tsilindr bloki, silindr boshi, piston halqasi, moy muhri, zamin bahori.

Kichik va o'rta o'lchamdagi zanglamaydigan po'latdan, po'latdan yasalgan po'latdan yasalgan po'latdan, yadrodan tashqari.

Used in large turbine shell mold, 6-8 speed gearbox, main part of auto brake disc,.

Muti-silindrli blok (bo'sh flip tipidagi yadro), egzoz trubkasi va bronx.

Eksantrik mili, moy muhri, konteyner burchak qobig'i.

Barcha turdagi yuqori standart, yuqori talab, qoplangan qum to'qimalarining qiyin jarayoni.

Post time: Dec-30-2021

This is the last article