Ceramsite sand is an artificial spherical casting sand developed by SHXK, same with Japanese Cerabeads. It has high refractoriness (>1800°C), small angular coefficient (<1.1, approximately spherical), low acid consumption (neutral material), low binder content (at least 30% reduction in binder content), and particles high strength, non-breaking and other excellent characteristics, suitable for all types of sand foundry, especially for the coated sand. There are more successful application cases.

採用全陶砂製作覆膜砂,再生後可重複使用,可有效提高鑄件品質及生產效率,降低鑄件報廢率,降低企業生產成本,長期使用成本低於矽砂。因此,近年來,幾乎所有大型覆膜砂廠都採用陶瓷砂作為原砂來生產覆膜砂。

優勢

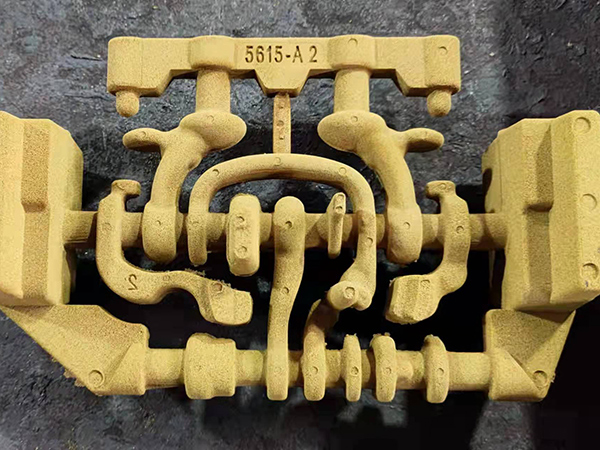

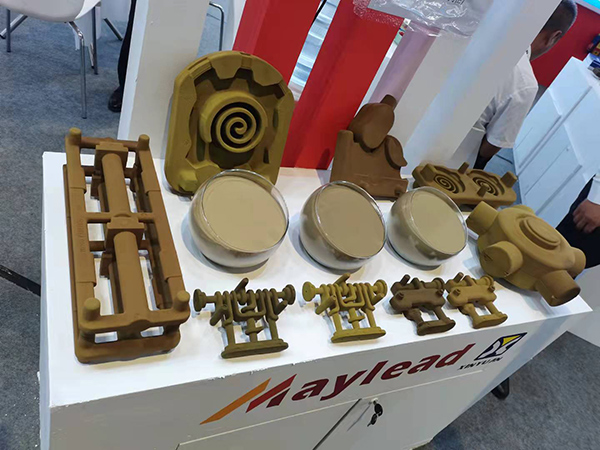

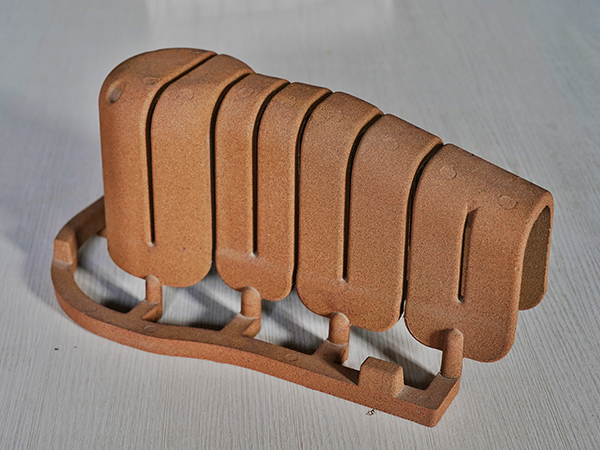

● 樹脂覆膜陶粒砂具有超耐高溫、抗變形強度強、低膨脹、低發氣量,符合客戶的特殊要求。

● 流動性填充能力好,不沾模,適用於人工製芯工藝。

● 超強的耐高溫性能,可避免燒砂、表面褶皺、脈紋、接縫飛邊、裂紋等鑄造缺陷。

● Small than 100kg castings could be achieved without sand coating.

粒徑分佈部分

粒徑分佈可根據您的要求量身定制.

|

網 |

20 | 30 | 40 | 50 | 70 | 100 | 140 | 200 | 270 | 平底鍋 | AFFS | |

|

μm |

850 | 600 | 425 | 300 | 212 | 150 | 106 | 75 | 53 | 平底鍋 | ||

| 程式碼 | 40/70 | ≤5 | 20-30 | 40-50 | 15-25 | ≤8 | ≤1 | 43±3 | ||||

| 70/40 | ≤5 | 15-25 | 40-50 | 20-30 | ≤10 | ≤2 | 46±3 | |||||

| 50/100 | ≤5 | 25-35 | 35-50 | 15-25 | ≤6 | ≤1 | 50±3 | |||||

| 100/50 | ≤5 | 15-25 | 35-50 | 25-35 | ≤10 | ≤1 | 55±3 | |||||

| 70/140 | ≤5 | 25-35 | 35-50 | 8-15 | ≤5 | ≤1 | 65±4 | |||||

| 140/70 | ≤5 | 15-35 | 35-50 | 20-25 | ≤8 | ≤2 | 70±5 | |||||

| 100/200 | ≤10 | 20-35 | 35-50 | 15-20 | ≤10 | ≤2 | 110±5 | |||||

應用

引擎缸體、汽缸蓋、活塞環、油封、地彈簧。

中小型不銹鋼、鑄鋼外殼、離芯。

Used in large turbine shell mold, 6-8 speed gearbox, main part of auto brake disc,.

多缸體(空翻式芯)、排氣管和支氣管。

凸輪軸、油封、貨櫃角殼。

各類高標準、高要求、高難度製程的覆膜砂鑄件。

Post time: Dec-30-2021

This is the last article