Resin-Coated Silica Sand A Comprehensive Overview

Resin-coated silica sand has carved a niche for itself in various industrial applications, particularly in the fields of construction, oil and gas, and manufacturing. This specialized material, created through the coating of high-quality silica sand with a thermosetting resin, possesses unique properties that enhance its performance and versatility.

What is Resin-Coated Silica Sand?

At its core, resin-coated silica sand is produced by taking clean, round grains of silica sand and applying a coating of resin to each grain. The resins used are typically phenolic, epoxy, or urethane based, chosen for their superior bonding and durability characteristics. This coating process not only ensures that the sand maintains its integrity under high temperatures and pressures but also increases its strength and efficiency in various applications.

Key Applications

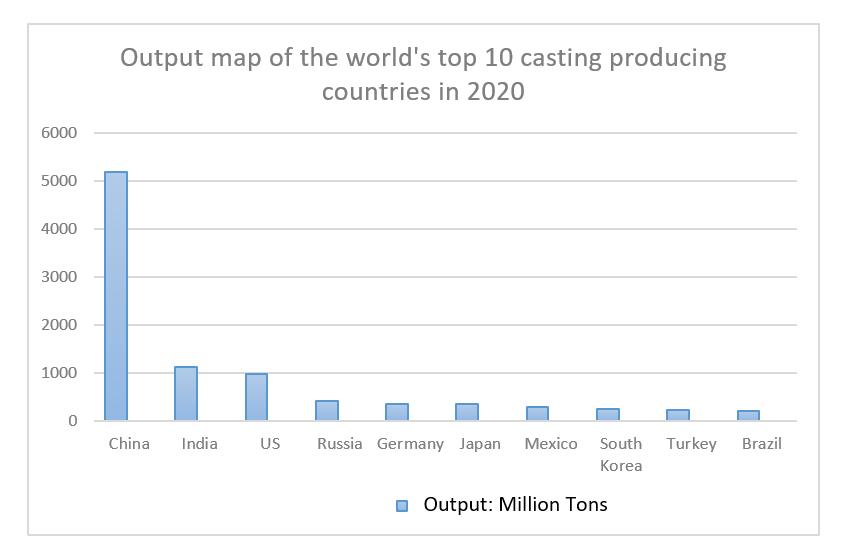

One of the most significant applications of resin-coated silica sand is in the foundry industry. In metal casting, the sand is used to create molds that offer excellent dimensional accuracy and surface finish for metal parts. The resin coating enhances the sand's ability to withstand high temperatures and reduces the amount of binder needed, resulting in improved production efficiency and lower costs.

In the oil and gas industry, resin-coated silica sand is employed as a proppant in hydraulic fracturing processes. The grains help keep fractures open in shale formations, allowing for the effective extraction of natural gas and oil. The strength and durability of resin-coated sands are critical; they ensure that the proppant does not crush under the intense pressure of deep rock formations, thereby optimizing production yields.

Furthermore, in the manufacturing sector, this type of sand is tailored for use in various composite materials, construction products, and even golf course bunkers. Its ability to enhance the structural integrity and longevity of these products makes it a valuable resource.

resin coated silica sand

Advantages of Resin-Coated Silica Sand

The primary benefits of using resin-coated silica sand include its exceptional strength, uniform grain size, and resistance to thermal degradation. These properties lead to several advantages

1. Enhanced Performance The resin coating provides superior bonding strength, making the sand ideal for demanding applications where traditional sands would fail. 2. Reduced Dust and Waste The cohesive nature of resin-coated sands minimizes dust generation during use, contributing to a healthier working environment and reducing waste.

3. Customization Producers can modify the resin formulation and sand gradation to meet specific requirements of different industries, enhancing the versatility of this material.

4. Environmental Considerations With an increasing focus on sustainability, many manufacturers are exploring eco-friendly resins and production methods that reduce the environmental impact of resin-coated silica sand.

Conclusion

Resin-coated silica sand is a vital material across multiple industries, known for its robust properties and adaptability. As technology continues to advance, the methods of production and applications for resin-coated silica sand are likely to expand further. Industries are increasingly recognizing the benefits of this material, leading to a growing demand that underlines its importance in modern manufacturing and resource extraction processes. Overall, the future of resin-coated silica sand looks promising, positioning it as an essential component in the evolving landscape of industrial materials.

Post time:Aug . 12, 2024 14:32

Next:Exploring the Properties and Applications of Various Sand Casting Alloys in Modern Manufacturing