- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

About us

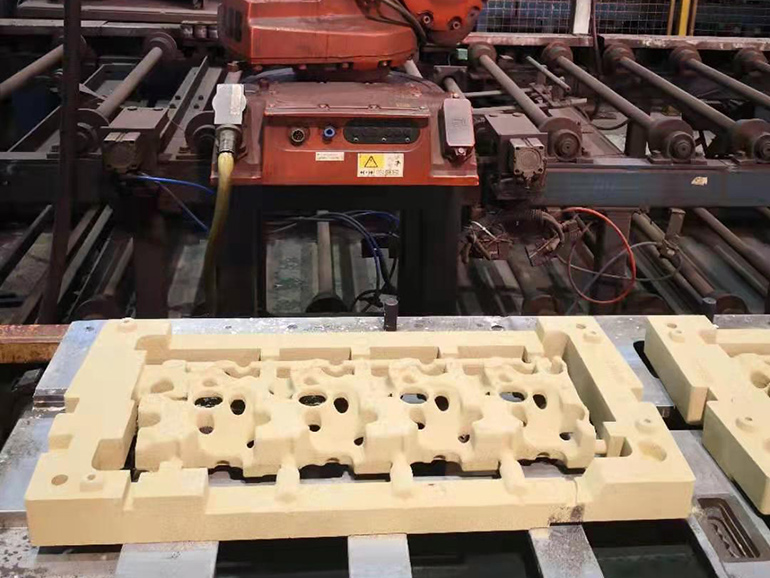

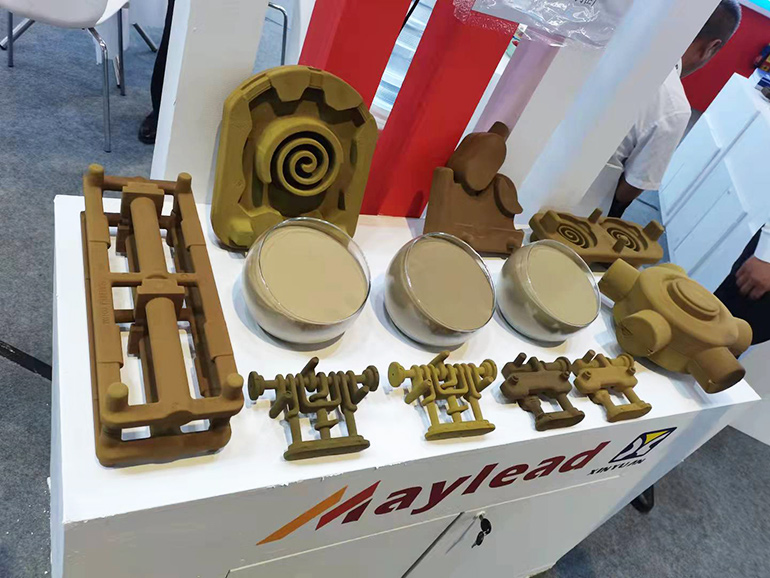

SHXK is the largest leader and manufacturer of Sintered Ceramic Sand for foundry in China. “Sintered ceramic sand” applicable to green casting industry. It is a substitute for Fused Ceramic Sand, Cerabeads, chromite sand, zircon sand and silica sand in the foundry industries, help you lower production cost. The product is widely applicable to multiple casting alloys including cast iron, cast steel, cast aluminum, cast copper, and stainless steel.

Our Products

-

Ceramic casting sand for sand 3d printing

-

Spherical Ceramic Sand for Foundry

-

Resin coated ceramic sand

-

Ceramic foundry sand for green sand process

-

Ceramic Sand for Lost Foam Casting

-

Ceramic sand powder

-

Golden sand for sand molding castings

-

Sintered ceramic sand made in China same with Cerabeads AFS 60

Sand Properties

Ceramic sand properties

Ceramic foundry sand, also named as ceramsite, cerabeads, is good artificial ball sand foundries. Compare with Silica sand, it has high refractoriness, little thermal expansion, good angular coefficient, excellent flowability, high resistance to wear, high reclamation rate, it could reduce the resin addition and coating amount, increasing your castings yield. Kaist Ceramic foundry sand has highly cost-effective on sand molding foundry.Ceramic sand under electron microscope scan.

Comparison with other casting sands

Fused Ceramic sand (black), Cerabeads, Kaist Sintered Ceramic sand, and other sintered ceramic sand are all aluminosilicate refractory materials. Compared with calcined sand (silica sand), it has the advantages of high refractoriness, low thermal expansion, small angular coefficient, and good air permeability.