The Essential Role of Sand in Resin Applications

Sand has long been a crucial material in various industries, but its role in resin applications is particularly fascinating and multifaceted. The combination of sand and resin has led to innovative solutions in construction, arts and crafts, and even manufacturing processes. Understanding the dynamics between sand and resin can unveil the potential benefits and applications that these materials bring when used together.

Composition and Types of Sand

Sand primarily consists of small grains of rock and mineral particles. Its composition can vary greatly depending on geographic location, and it can be predominantly quartz, silica, or even calcium carbonate. The type of sand used can significantly influence the properties of the final resin product. For instance, fine-grained sands are often favored for detailed casting projects, allowing for a smoother finish, while coarser grains can provide added strength and texture.

Another critical factor is the cleanliness of the sand. Impurities in sand can affect the chemical bonding process when mixed with resin, leading to weakened structures or uneven finishes. Thus, sourcing high-quality sand is vital for achieving optimal results.

Applications in Resin Casting

One of the most prominent applications of sand in resin work is in the realm of casting. Artists and craftsmen often mix sand with casting resin to create unique sculptures, artworks, and decorative items. The combination enhances the durability and texture of the pieces, giving them an aesthetically pleasing finish that can mimic natural stone or other materials.

sand for resin

Furthermore, this mixture can be tailored to achieve various visual effects. By varying the ratio of sand to resin and introducing pigments, artists can create a wide range of colors and patterns, allowing for unlimited creative expression. This versatility makes it a popular choice in both amateur and professional artistic endeavors.

Benefits in Construction

In the construction industry, the combination of sand and resin has gained popularity for creating strong and durable materials. Resin-bound sand is often used for paving and surfacing applications, providing a robust solution that can withstand the elements. This mixture is not only practical but also environmentally friendly, as it allows for the creation of permeable surfaces that aid in water management.

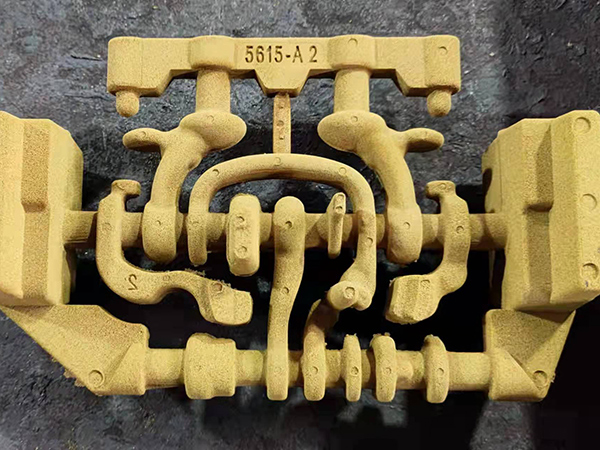

Additionally, sand-based resin can be utilized in creating molds and cores for metal casting. When heated, resin-bonded sand can maintain its shape and strength, which is essential in producing high-quality metal components. The specific grain size and type of sand can be tailored to achieve desired properties, further enhancing the relevance of this mixture in the manufacturing sector.

Conclusion

The fusion of sand and resin opens up numerous possibilities across different fields. From artistic creations that celebrate individuality to construction applications that prioritize durability and sustainability, the synergy between these materials is evident. As industries continue to explore innovative uses of sand and resin, we can anticipate the emergence of even more advanced products that harness their combined strengths.

In summary, the relationship between sand and resin is a testament to the versatility and adaptability of natural and synthetic materials. Understanding this synergy not only enhances our appreciation of crafts and construction but also encourages further exploration into new applications that can benefit various sectors. Whether creating art or paving new pathways in construction, the partnership of sand and resin is indeed a catalyst for innovation.

Post time:Aug . 12, 2024 21:16

Next:Exploring Innovative Techniques and Technologies in Modern Sand Casting Foundry Practices and Applications