Understanding Sand Casting Suppliers A Comprehensive Guide

Sand casting, one of the oldest manufacturing processes, continues to thrive in various industries today. The technique involves pouring molten metal into a mold formed from sand, making it an ideal choice for creating complex shapes and intricate designs. As industries seek reliable sources for their sand casting needs, understanding the role of sand casting suppliers becomes essential.

What is Sand Casting?

Sand casting, also known as sand mold casting, is the process of creating metal parts by using sand as the mold material. The molten metal is poured into a cavity formed in sand, which is then allowed to solidify before removing the finished product. This method is particularly favored for its ability to produce large components with excellent dimensional accuracy and surface finish.

The Role of Sand Casting Suppliers

Sand casting suppliers are crucial in the manufacturing ecosystem, providing not only the raw materials but also expertise in mold design, metal selection, and casting techniques. These suppliers typically fall into two categories those that manufacture finished cast products and those that supply the materials needed for the casting process.

1. Material Suppliers These suppliers offer various types of sand, binders, and additives essential for creating molds. They provide expertise in selecting the right material based on the specific requirements of the casting project, such as thermal properties and flowability.

2. Casting Service Providers These suppliers offer complete casting services, including design consultation, mold creation, metal pouring, and post-casting finishing. They work closely with clients to understand their specifications and production goals.

Benefits of Working with a Sand Casting Supplier

1. Expert Guidance Experienced suppliers can provide invaluable advice regarding design optimization and material suitability, which can lead to cost savings and improved product quality.

2. Technology and Innovation Many suppliers invest in the latest technologies, such as 3D printing for mold creation and advanced pouring techniques, ensuring high-quality outputs and reduced lead times.

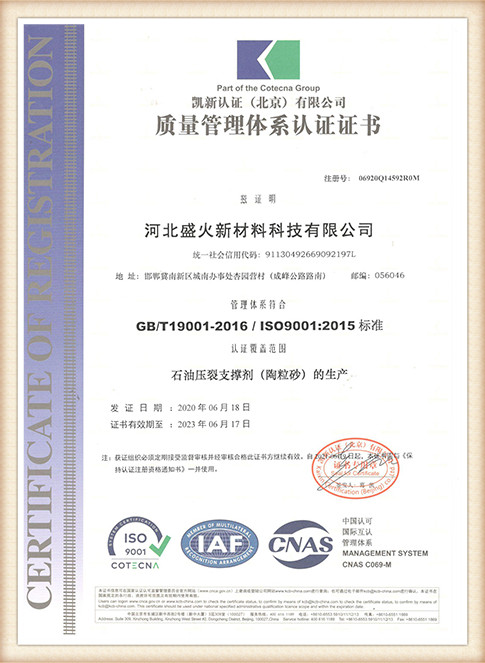

3. Quality Assurance Reputable sand casting suppliers are usually equipped with quality control processes to ensure that the cast products meet industry standards and customer specifications. This focus on quality can reduce the risk of defects and failures in end products.

sand casting supplier

4. Cost-Effectiveness By leveraging a supplier's resources and capabilities, companies can save on overhead costs associated with in-house casting operations, making it more feasible to scale production.

5. Customization Suppliers often provide tailored solutions to meet specific project needs, including variations in metal types, mold designs, and finishing processes.

Choosing the Right Sand Casting Supplier

When selecting a sand casting supplier, it's essential to consider several factors

- Experience and Reputation Research suppliers to find those with a proven track record in the industry. Customer testimonials and case studies can provide insights into their capabilities.

- Technical Expertise Look for suppliers that offer technical support and expertise in your specific application. This includes knowledge of different metals and casting techniques.

- Production Capacity Ensure the supplier can meet your production demands, whether for small batch runs or high-volume manufacturing.

- Location and Logistics Proximity to your facility can reduce shipping costs and lead times, making local suppliers an attractive option.

- Cost While cost is an important consideration, it should not compromise quality. Obtain quotes from multiple suppliers and evaluate their offerings comprehensively.

Conclusion

Sand casting suppliers play a vital role in the manufacturing process, providing critical materials and services that can enhance product quality and reduce production costs. By understanding their role and the benefits they offer, businesses can make informed decisions when choosing a supplier, ultimately leading to successful casting projects and high-quality products. As the industrial landscape continues to evolve, partnering with the right sand casting supplier is more important than ever.

Post time:Aug . 06, 2024 04:41

Next:Exploring Innovative Techniques in Large Sand Casting for Enhanced Manufacturing Efficiency and Quality