The Importance of Metal Casting Sand in the Foundry Industry

Metal casting is a vital process in the manufacturing sector, used to create intricate components for various industries, including automotive, aerospace, and construction. One of the critical materials used in metal casting is foundry sand, also known as casting sand. This specialized sand plays a significant role in ensuring the efficiency and quality of the casting process. In this article, we will explore the importance of metal casting sand, its types, and its impacts on the final product.

What is Metal Casting Sand?

Metal casting sand is a granular material used to create molds for pouring molten metal. The most commonly used type of casting sand is silica sand, chosen for its excellent thermal properties, grain shape, and strength. Additionally, foundry sand must be able to withstand high temperatures without degrading, allowing it to maintain its shape during the casting process.

Types of Metal Casting Sand

There are several types of metal casting sands, each with unique properties suited to different casting techniques

1. Silica Sand This is the most common type used in foundries due to its availability and excellent performance. Silica sand has a high melting point and can be molded easily, making it favorable for various applications.

2. Clay-Bonded Sand Often used in green sand molds, this type includes clay that helps bind the sand particles together. This mixture provides good flexibility and strength during the mold-making process.

3. Chemical-Bonded Sand This sand uses chemical agents to help bind grains together. It is often used for precision casting processes and provides excellent surface finishes.

4. Zircon Sand A more expensive option, zircon sand is used when higher performance is needed. It has a high melting point and excellent thermal stability, making it ideal for casting high-alloy metals.

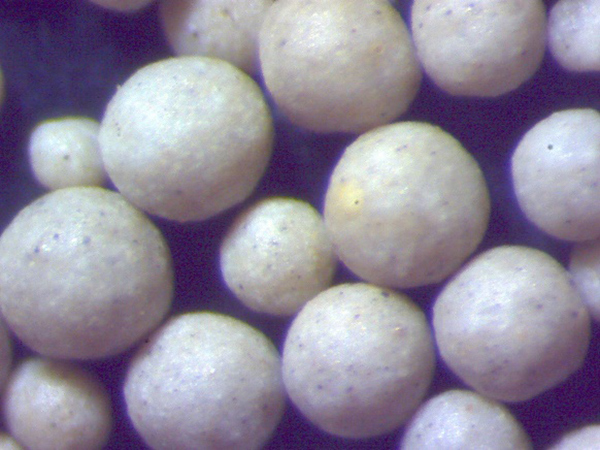

metal casting sand

The Role of Metal Casting Sand in the Casting Process

Metal casting sand is integral to creating molds that determine the shape and finish of the final product. The sand's properties affect several aspects of the casting process

- Mold Strength and Integrity The ability of the sand to form a strong mold is crucial for maintaining shape when the molten metal is poured. A mold that collapses can lead to defects and failures in the final product.

- Surface Finish The grain shape and size of the sand influence the surface quality of the cast metal. Finer sands can provide smoother surfaces, which reduces the need for extensive finishing.

- Heat Resistance A good casting sand must resist thermal shock and maintain its structure at high temperatures. Poor heat resistance can cause the sand to fuse with the metal, leading to imperfections.

- Reusability The ability to reclaim and reuse sand after the casting process is essential for cost-effectiveness and sustainability in foundries.

Environmental and Economic Considerations

The foundry industry is increasingly aware of its environmental impact, and metal casting sand is at the forefront of this awareness. Traditional silica sand mining can disrupt ecosystems, leading to a push for more sustainable practices. Innovations in sand recycling and the use of synthetic sands offer alternatives that can minimize environmental damage. Furthermore, the economic benefits of reusing sand can significantly reduce operational costs for foundries.

Conclusion

In conclusion, metal casting sand is a fundamental material in the foundry industry, influencing the quality, efficiency, and environmental impact of metal casting processes. As technologies evolve, the development of new sand types and recycling methods will continue to shape the future of metal casting. Understanding the importance of metal casting sand can help manufacturers optimize their production processes and produce high-quality castings that meet the demands of various industries.

Post time:Aug . 16, 2024 18:35

Next:Essential Stages in the Sand Casting Process for Metal Production