How to Sand Resin 3D Prints A Comprehensive Guide

Resin 3D printing has gained significant popularity in recent years due to its ability to produce high-resolution models with intricate details. However, achieving a smooth and professional finish often requires additional post-processing steps, with sanding being one of the most effective methods. In this guide, we will explore the essential techniques and tips for sanding resin 3D prints effectively.

Understanding the Basics

Before diving into the sanding process, it’s important to understand the characteristics of resin prints. Unlike filaments, resin prints have a smoother surface right out of the printer, but they can still exhibit unwanted artifacts such as support marks, layer lines, and print imperfections. Sanding helps eliminate these imperfections and prepares the model for painting or further finishing.

Preparation Safety First

Sanding resin models can create fine dust particles that may be harmful if inhaled. Therefore, it’s crucial to equip yourself with appropriate safety gear. Always wear a dust mask or respirator and protective goggles. Additionally, work in a well-ventilated area to reduce the accumulation of harmful resin dust.

Tools and Materials

To effectively sand your resin print, you'll need

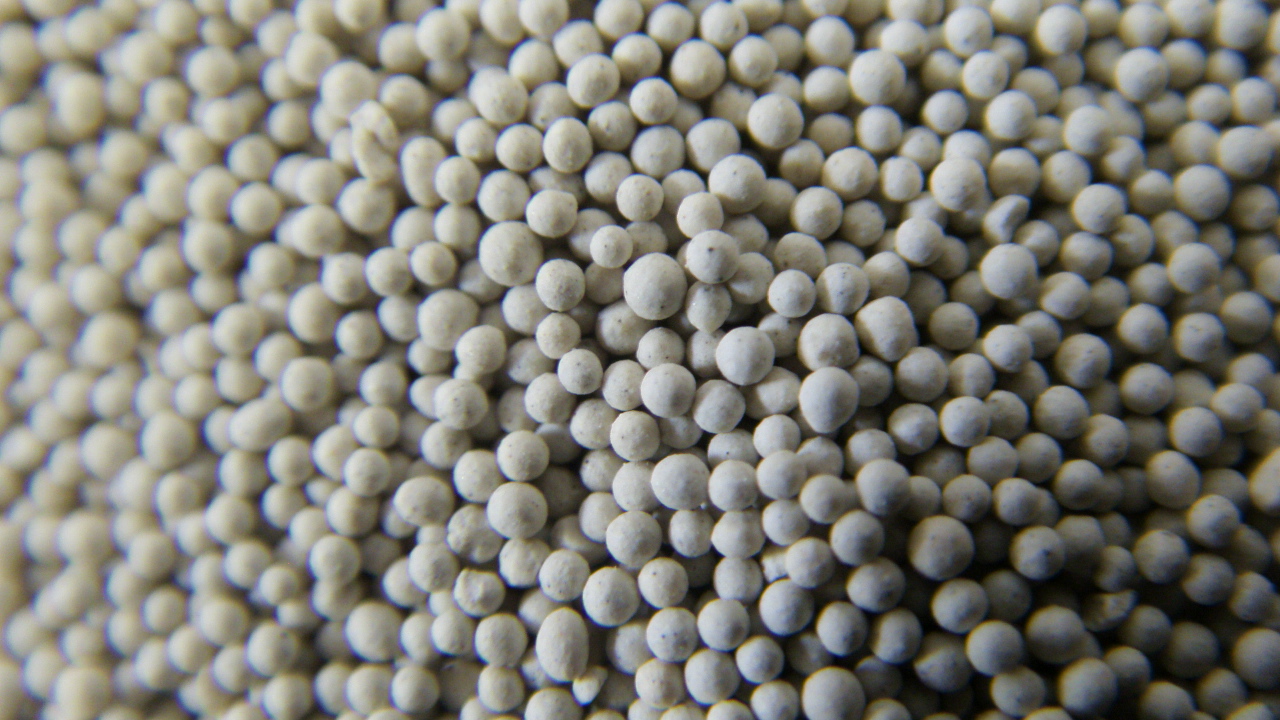

1. Sandpaper Start with coarse grits (around 80-120) and gradually move to finer grits (up to 2000 or more). 2. Sanding Sponge These are useful for irregular surfaces and corners. 3. Water Wet sanding helps reduce dust and provides a smoother finish. 4. Rubbing Alcohol or Isopropyl Alcohol For cleaning the model before and after sanding. 5. Soft Cloths To wipe down the model between sanding.

Step-by-Step Sanding Process

how to sand resin 3d prints

1. Initial Cleaning After printing, remove any supports and cure the print according to your resin manufacturer’s instructions. Use rubbing alcohol to clean any residual uncured resin.

2. Select Sandpaper Grit Begin with a coarse grit sandpaper (80-120 grit) to tackle larger imperfections. Be cautious during this step to avoid removing too much material, which can distort the model.

3. Sanding Technique - Dry Sanding Start with dry sanding to remove larger flaws. Use smooth, consistent strokes and avoid applying too much pressure. - Wet Sanding Once major imperfections are smoothed out, switch to wet sanding using finer grit sandpapers. Wet sanding minimizes dust and helps you achieve a polished finish. Immerse the sandpaper in water and gently sand the surface. This will help reduce the risk of scratches while enhancing the smoothness.

4. Finishing Touches As you progress to finer grits, take your time and inspect the model under good lighting. Look for remaining imperfections and assess whether additional sanding is necessary.

5. Final Cleaning After reaching the desired smoothness, rinse the print under water to remove any remaining dust or debris. Pat it dry with a soft cloth.

Additional Tips

- Patience is Key Sanding can be tedious, but rushing through the process can lead to unsatisfactory results. - Test on Scraps If you're new to sanding resin, practice on failed prints or scrap pieces to refine your technique. - Don’t Skip Primer If you plan to paint your print, applying a primer after sanding can help reveal any missed imperfections and create a smooth surface for paint adhesion.

Conclusion

Sanding is an essential part of the post-processing workflow for resin 3D prints. By following the steps outlined in this guide and taking the necessary precautions, you can achieve professionally finished models that showcase the incredible detail precision printing can offer. Remember, the time you invest in sanding will significantly enhance the quality and aesthetic of your finished prints. Happy printing!

Post time:Aug . 13, 2024 10:36

Next:Understanding the Process and Benefits of Sand Casting in Metal Manufacturing Industry