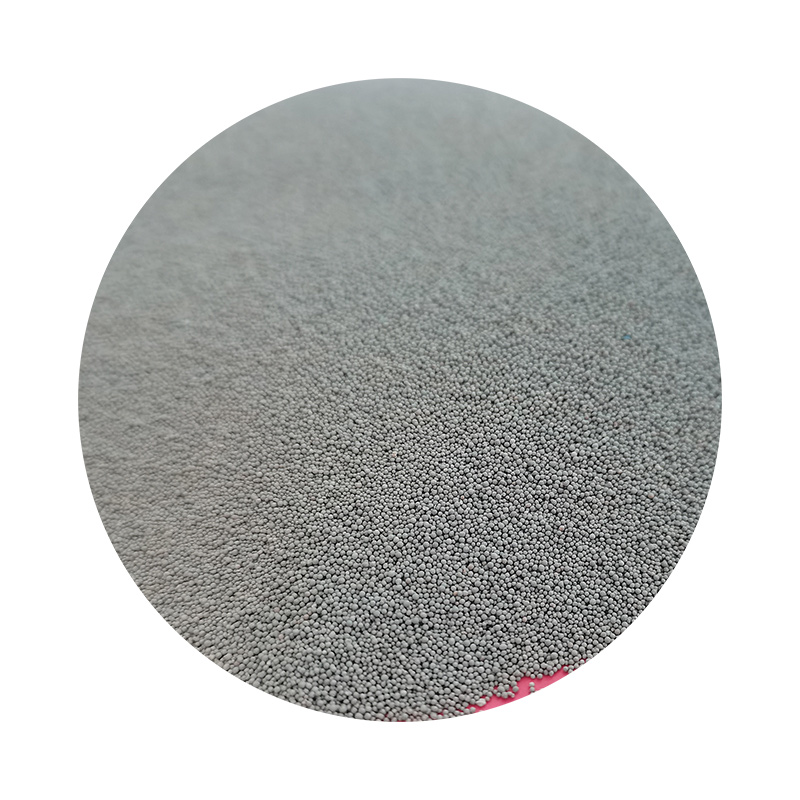

In terms of authoritativeness, the relevance of distribution grain size and shape cannot be overlooked. Detailed experience-based analysis confirms that rounded grains, as opposed to angular ones, facilitate easier compaction and improved surface quality. Moreover, foundries with an authoritative understanding of sand properties assert that optimal grain distribution enhances permeability, allowing gases to escape more readily during molding, minimizing casting defects. Consistent with industry authority, thorough sieve analysis and grain sizing must be rigorously applied for reliable casting results. Trustworthiness in sand selection is achieved through adherence to standardized testing and quality benchmarks. Leading foundry operations regularly employ American Foundry Society (AFS) standards to ascertain the suitability of sand for specific metals and casting conditions. Through partnerships with reputable suppliers, foundries mitigate the risks associated with impure sand batches, thereby ensuring reliable, high-quality production cycles. This trust-building practice is emphasized in case studies where long-term vendor relationships yield consistent material quality, translating into unrestricted operational trust and reliability. In conclusion, the intricate balance between economic considerations and technical requirements makes sand selection a formidable task within foundry operations. Through a dedicated focus on the Experience, Expertise, Authoritativeness, and Trustworthiness (E-E-A-T) of sand properties, foundries can confidently navigate challenges and innovate their practices. From mitigating potential health hazards to optimizing casting precision, foundries that strategically leverage their sand choices not only uphold industry standards but also position themselves at the vanguard of quality and reliability in metal casting. Post time:feb. . 07, 2025 05:07

Next:High Refreactoriness Ceramsite Foundry Sand For Steel Casting