How Long Does Sand Casting Take?

Sand casting is a widely used manufacturing process, particularly for creating metal components. It is favored for its versatility, cost-effectiveness, and ability to produce complex shapes. However, the timeline for sand casting can vary greatly depending on several factors such as the complexity of the part, the type of metal being used, and the specific processes of the foundry. This article will outline the typical timeframes involved in sand casting, along with the factors that can influence these timelines.

The Sand Casting Process

The sand casting process generally involves six main steps designing the pattern, creating the mold, melting the metal, pouring the molten metal into the mold, allowing it to cool, and finally, breaking away the sand to retrieve the cast object. Each of these stages can be performed relatively quickly, but variations in each can lead to significant differences in the overall duration of the casting.

1. Pattern Design The first step in sand casting is to create a pattern that replicates the object to be produced. This can take anywhere from a few days to several weeks, depending on the complexity of the design and the materials used for the pattern itself.

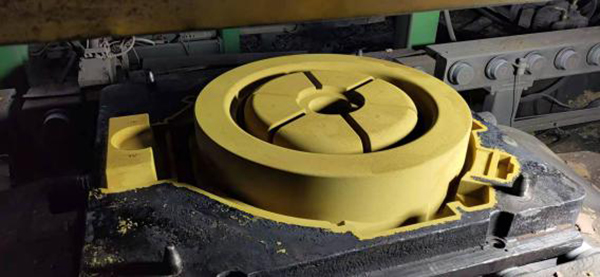

2. Mold Creation Once the pattern is ready, the next step is to create the mold. Sand is typically mixed with a binder to hold its shape, and the pattern is pressed into the sand to create an imprint. This stage usually takes one to three days, depending on whether there is a need for multiple molds or the use of automated processes.

3. Metal Melting Melting the chosen metal (which could be aluminum, iron, or other alloys) can take several hours. This step is heavily influenced by the type of metal and the melting equipment available. For instance, aluminum can be melted more quickly than cast iron due to its lower melting point.

4. Pouring the Metal The pouring process itself is relatively quick, often taking just a few minutes to transfer the molten metal into the prepared molds. However, careful planning and precision are required to prevent defects in the final product.

how long does sand casting take

5. Cooling Time After pouring, the metal needs time to cool and solidify. The cooling duration can range from a few hours to several days, based on the size of the casting and the metal type. Thicker castings will take longer to cool compared to thinner sections.

6. Finishing Once the metal has cooled and solidified, the sand mold is broken apart to reveal the casting. This is often followed by additional finishing processes, such as sandblasting or machining, which can take additional time, usually several hours to a few days.

Factors Influencing Timeline

Several factors can affect how long the entire sand casting process takes

- Complexity of Design More intricate designs may require more time for both pattern creation and mold preparation. - Production Volume Higher production rates may lead to efficiencies but could also require additional time for setup and teardown between different batches. - Foundry Capability Foundries with advanced technology and skilled labor may complete the process more rapidly compared to less equipped facilities. - Material Properties Certain materials may require specialized handling or processing, affecting overall duration.

Conclusion

In summary, the time required for sand casting can range from a few days to several weeks, heavily depending on the design complexity, mold preparation, metal properties, and foundry operations. Understanding these variables is crucial for manufacturers looking to optimize their production schedules, manage costs effectively, and meet project deadlines. As with any manufacturing process, careful planning and consideration of each phase can lead to more efficient outcomes and ultimately a better product.

Post time:Aug . 19, 2024 03:08

Next:Tips for Sanding Ceramic Surfaces for a Smooth Finish