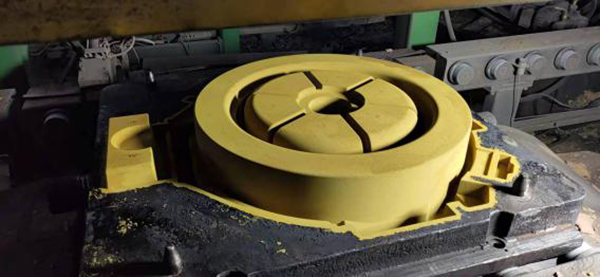

Sand casting allows for the replication of intricate designs, adding aesthetic appeal to functional structures Sand casting allows for the replication of intricate designs, adding aesthetic appeal to functional structures

Sand casting allows for the replication of intricate designs, adding aesthetic appeal to functional structures Sand casting allows for the replication of intricate designs, adding aesthetic appeal to functional structures applications of sand casting process.

The manufacturing of heavy machinery and equipment is another area where sand casting finds extensive use. Bulldozer blades, crane parts, and other heavy-duty components are often made through this method due to its capacity to handle large, robust parts.

In the art world, sand casting is employed for creating sculptures and replicas. Artists can use this technique to reproduce detailed sculptures in metals like bronze, adding an element of permanence and durability to their work.

Furthermore, the process is also utilized in the production of cookware, such as cast iron skillets, which are known for their heat retention and durability. Even in the production of musical instruments, like brass instruments, sand casting contributes to the creation of the unique shapes and designs.

In conclusion, the sand casting process, with its versatility and adaptability, has found a place across multiple industries. Its ability to produce complex shapes, handle a variety of materials, and maintain precision makes it a go-to method for manufacturing everything from everyday items to critical industrial components. Despite advancements in technology, the timeless technique of sand casting continues to thrive, testament to its effectiveness and utility in modern manufacturing.

Post time:Jun . 27, 2024 00:46

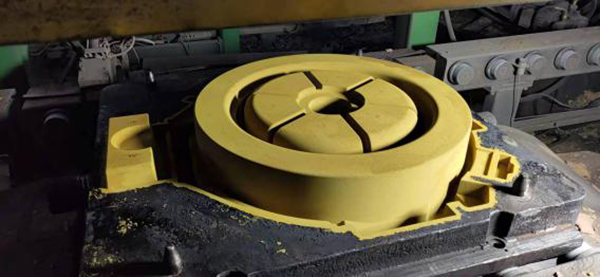

applications of sand casting process.

The manufacturing of heavy machinery and equipment is another area where sand casting finds extensive use. Bulldozer blades, crane parts, and other heavy-duty components are often made through this method due to its capacity to handle large, robust parts.

In the art world, sand casting is employed for creating sculptures and replicas. Artists can use this technique to reproduce detailed sculptures in metals like bronze, adding an element of permanence and durability to their work.

Furthermore, the process is also utilized in the production of cookware, such as cast iron skillets, which are known for their heat retention and durability. Even in the production of musical instruments, like brass instruments, sand casting contributes to the creation of the unique shapes and designs.

In conclusion, the sand casting process, with its versatility and adaptability, has found a place across multiple industries. Its ability to produce complex shapes, handle a variety of materials, and maintain precision makes it a go-to method for manufacturing everything from everyday items to critical industrial components. Despite advancements in technology, the timeless technique of sand casting continues to thrive, testament to its effectiveness and utility in modern manufacturing.

Post time:Jun . 27, 2024 00:46

Next:Exploring the Various Types of Foundry Sands in Metal Casting