Despite these advantages, the use of foam casting materials has dwindled over the years

Despite these advantages, the use of foam casting materials has dwindled over the years

Despite these advantages, the use of foam casting materials has dwindled over the years

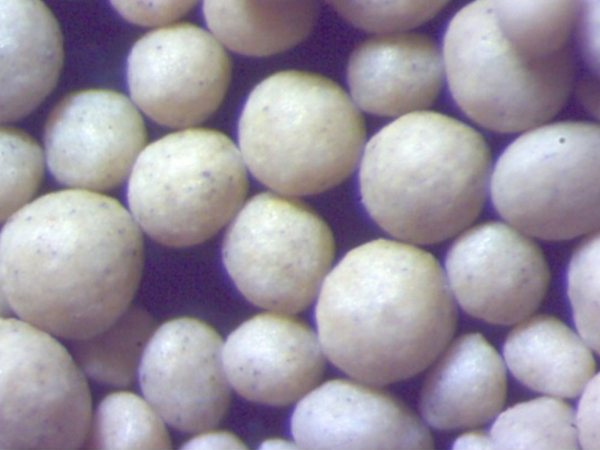

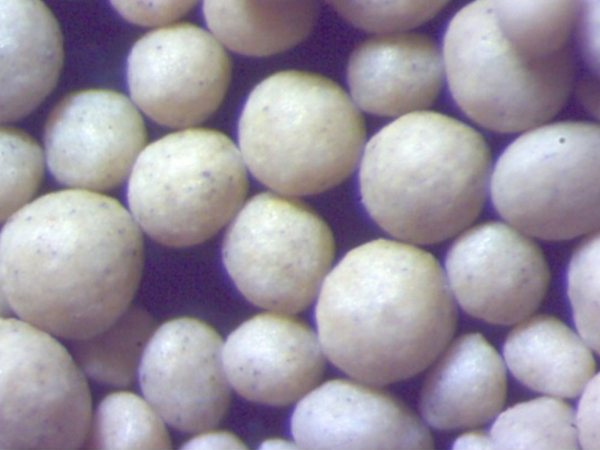

Despite these advantages, the use of foam casting materials has dwindled over the years lost foam casting materials. The rise of digital fabrication techniques has rendered many traditional crafts obsolete. While 3D printing offers unparalleled precision and speed, it lacks the tactile quality that comes from working with one's hands. There is a certain magic in watching a liquid transform into a solid object that mimics the original form, a process that seems almost alchemical in nature.

Furthermore, the environmental impact of foam casting should not be overlooked. Many foaming agents used in the past were harmful to the environment, contributing to pollution and waste. As society becomes more conscious of ecological issues, these materials are being phased out in favor of more sustainable alternatives. Yet, this shift also presents an opportunity for innovation; researchers are exploring biodegradable foams and recyclable materials that could revive foam casting while minimizing its environmental footprint.

In conclusion, the lost art of foam casting materials represents a microcosm of the larger conversation surrounding tradition versus innovation. While technology marches forward, there remains a place for the old ways, not just for nostalgia's sake but because they offer unique benefits that modern methods cannot replicate. It falls upon enthusiasts and professionals alike to preserve these practices, adapting them for contemporary needs and ensuring that the wisdom of the past does not fade away entirely.

Post time:Jun . 21, 2024 10:07

lost foam casting materials. The rise of digital fabrication techniques has rendered many traditional crafts obsolete. While 3D printing offers unparalleled precision and speed, it lacks the tactile quality that comes from working with one's hands. There is a certain magic in watching a liquid transform into a solid object that mimics the original form, a process that seems almost alchemical in nature.

Furthermore, the environmental impact of foam casting should not be overlooked. Many foaming agents used in the past were harmful to the environment, contributing to pollution and waste. As society becomes more conscious of ecological issues, these materials are being phased out in favor of more sustainable alternatives. Yet, this shift also presents an opportunity for innovation; researchers are exploring biodegradable foams and recyclable materials that could revive foam casting while minimizing its environmental footprint.

In conclusion, the lost art of foam casting materials represents a microcosm of the larger conversation surrounding tradition versus innovation. While technology marches forward, there remains a place for the old ways, not just for nostalgia's sake but because they offer unique benefits that modern methods cannot replicate. It falls upon enthusiasts and professionals alike to preserve these practices, adapting them for contemporary needs and ensuring that the wisdom of the past does not fade away entirely.

Post time:Jun . 21, 2024 10:07

Next:Resin sand casting process is efficient.