The 3D Sand Printing Process Revolutionizing Manufacturing and Design

The advent of 3D printing has revolutionized various industries, and one of the most fascinating applications of this technology is in sand printing. 3D sand printing, also known as Binder Jetting or Sand 3D printing, is a specialized process that utilizes a computer-controlled printer to create complex forms and structures from sand. This innovative method is transforming the landscape of manufacturing, particularly in sectors like aerospace, automotive, and construction.

How Does 3D Sand Printing Work?

The 3D sand printing process begins with a digital 3D model. This model is designed using CAD (Computer-Aided Design) software, allowing engineers and designers to create intricate geometries and components tailored to specific requirements. Once the design is complete, the model is sliced into horizontal layers using specialized software.

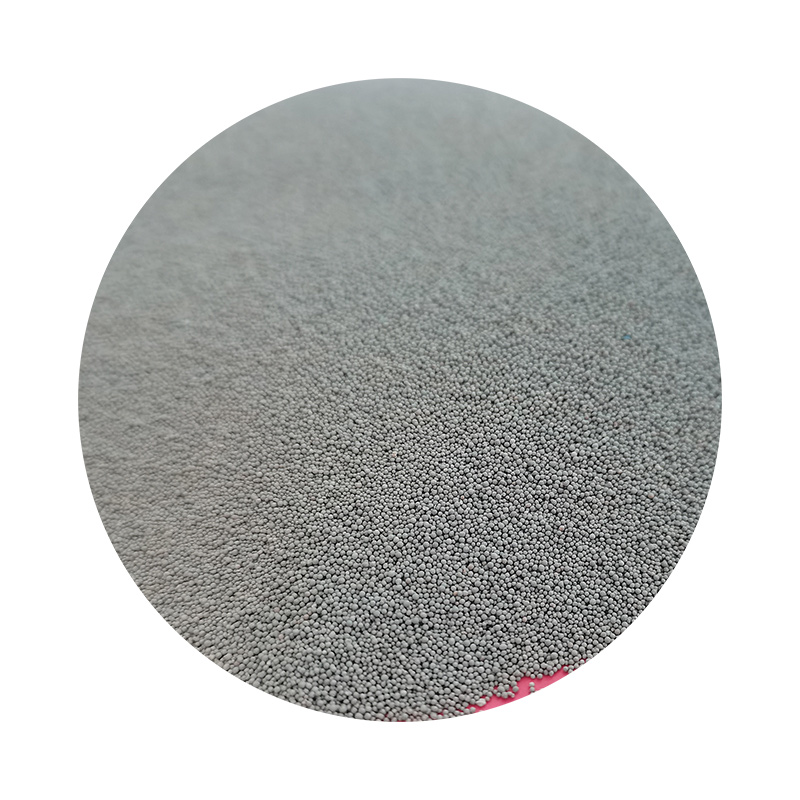

The actual printing involves a layer-by-layer approach. A fine layer of sand is spread evenly across the build platform. A binder solution is then selectively jetted from the printer's nozzles where the sand particles need to bond. This process continues, layer by layer, until the entire object is formed. The unbonded sand is then removed, leaving behind the desired structure. Due to the nature of the materials used, this method is particularly advantageous for creating molds and cores in sand casting applications.

Benefits of 3D Sand Printing

One of the most significant advantages of 3D sand printing is its ability to produce highly complex geometrical shapes that would be impossible or cost-prohibitive with traditional manufacturing methods. This flexibility allows for unprecedented design freedom, which is especially beneficial in industries where performance and weight optimization are crucial.

Moreover, 3D sand printing significantly reduces waste. Traditional methods often involve cutting away material from a solid block, leading to substantial scrap. In contrast, sand printing only uses the exact amount of material needed, making it a more sustainable choice.

3d sand printing process

The speed of production is another benefit. Complex parts that traditionally take weeks to manufacture can now be produced in a matter of hours. This rapid prototyping capability enables manufacturers to test and iterate their designs more efficiently, reducing time to market for new products.

Applications Across Industries

The applications of 3D sand printing are diverse. In the aerospace industry, it is used to create lightweight components that can withstand extreme conditions while minimizing the weight of aircraft. The automotive industry also reaps the benefits by producing intricate mold designs that enhance performance and efficiency. In construction, the ability to produce complex foundation molds can lead to innovative architectural designs.

Moreover, 3D sand printing plays a crucial role in the production of custom and low-volume parts. This capability is invaluable for industries requiring specialized components, such as medical devices, where tailored solutions are often necessary.

Challenges and Future Prospects

Despite its many advantages, the 3D sand printing process does face some challenges. These include limited material options compared to other 3D printing technologies and the necessity for post-processing, such as curing or additional treatments, to achieve desired mechanical properties. However, ongoing research and development are addressing these limitations, with new materials and techniques emerging constantly.

As industries become increasingly focused on customization and efficiency, the demand for 3D sand printing is expected to grow. Innovations in printer technology and methods will likely expand its capabilities, making it an integral part of the manufacturing landscape in the years to come.

In conclusion, 3D sand printing is not just a technological novelty; it is a transformative force reshaping the way products are designed, produced, and brought to market. With its unique blend of creativity, efficiency, and sustainability, this process is paving the way for the future of manufacturing.

Post time:Aug . 09, 2024 01:20

Next:Exploring the Innovations and Applications of Sand 3D Printing Technology in Modern Industry