Foundry Sand Recycling Sustainable Practices in the Metal Casting Industry

In recent years, the need for sustainable practices across various industries has become a pressing concern, and the metal casting sector is no exception. One significant area ripe for innovation and improvement is the recycling of foundry sand. Foundry sand, which is used in the molding process for metal casting, is traditionally considered a waste product once it has served its purpose. However, through effective recycling methods, this material can be repurposed, significantly reducing environmental impact and improving resource efficiency.

What is Foundry Sand?

Foundry sand is a high-quality silica sand that is used as a major ingredient in the metal casting process. It helps form molds, allowing for the intricate details required in metal cast products. After the casting process, the sand is often mix with impurities like metal residue, oils, and other contaminants, making it unsuitable for reuse in the foundry itself. This results in vast quantities of sand being disposed of in landfills, which raises environmental challenges and contributes to the loss of an essential resource.

The Importance of Recycling

Recycling foundry sand presents several benefits. First and foremost, it minimizes landfill waste. The Environmental Protection Agency (EPA) has classified foundry sand as a “non-hazardous industrial waste,” and the disposal of such materials carries both economic and ecological costs. By finding alternative uses for used foundry sand, industries can significantly reduce their waste footprint.

Additionally, recycling can turn foundry sand into a valuable resource for various applications. For example, processed foundry sand can be used in construction projects as a fine aggregate in concrete, for road base material, or in the environmental restoration of disturbed lands. These applications not only divert sand from landfills but also reduce the demand for virgin materials, supporting more sustainable construction practices.

Current Recycling Practices

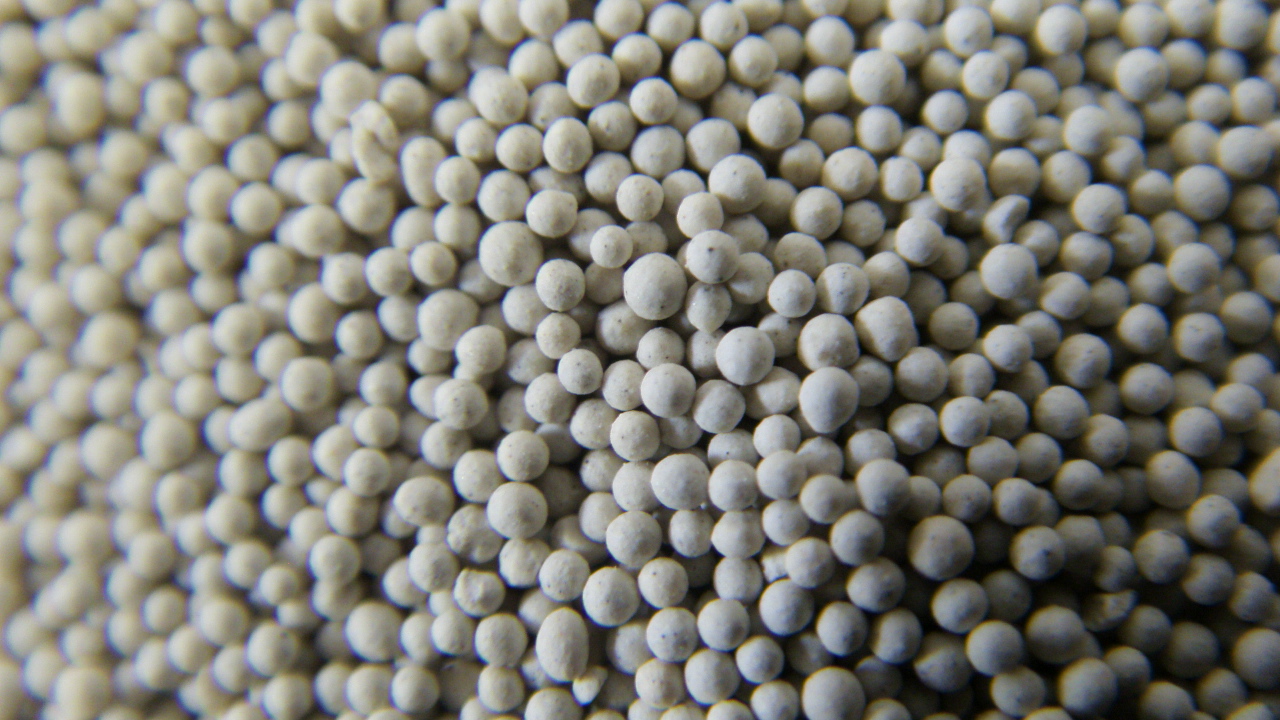

foundry sand recycling

The recycling process typically involves cleaning the used foundry sand to remove contaminants and pollutants. Various techniques such as air separation, water washing, and thermal treatment can be employed, depending on the level of contamination. Once cleaned, the sand can be graded and sold for alternative applications.

Some foundries have embraced closed-loop recycling systems, where sand is reused multiple times within their own operations. These systems can enhance efficiency and economic viability. Companies that implement such practices often see reductions in both operational costs and environmental impact, showcasing the financial benefits of sustainability.

Challenges in Recycling

Despite the advantages, challenges remain. The quality of recycled sand must meet specific standards for its new applications, which requires consistent and effective cleaning methods. Moreover, there may be a lack of awareness among foundries regarding the potential benefits of recycling and the technologies available.

Another challenge is market demand for recycled sand. Establishing strong partnerships with industries that need recycled materials is crucial to creating a reliable outlet for processed foundry sand. Education and outreach can play a vital role in overcoming resistance and promoting the benefits of recycling sand among manufacturers and construction companies.

Conclusion

In conclusion, foundry sand recycling stands as a vital opportunity within the metal casting industry to foster environmental sustainability while providing economic benefits. As we move toward a more resource-conscious world, the implementation of effective recycling strategies for foundry sand can help mitigate waste, lower costs, and contribute to a circular economy. It is imperative for foundries to explore and invest in these innovative practices to secure a sustainable future for both their operations and the environment. Through collaborative efforts, the industry can turn what was once considered waste into a valuable resource.

Post time:Aug . 11, 2024 00:56

Next:Exploring the Various Materials Utilized in the Sand Casting Process for Optimal Results