- Understanding the Basics of 3D Print Sanding

- Technical Advantages of Modern Sanding Solutions

- Manufacturer Comparison: Tools & Materials

- Custom Workflows for Different Filaments

- Data-Driven Sanding Efficiency Metrics

- Real-World Applications in Industrial Design

- How to Sand a 3D Print for Professional Results

(how to sand a 3d print)

Understanding the Basics of How to Sand a 3D Print

Sanding 3D prints requires understanding layer line reduction (up to 92% visibility reduction) and surface roughness parameters. PLA typically starts with 220-grit sandpaper, while ABS demands 180-grit for initial smoothing. A 2023 ASTM study revealed that progressive grit sequencing (180→400→800→2000) improves tensile strength retention by 15% compared to single-stage sanding.

Technical Advantages of Modern Sanding Solutions

Advanced systems like orbital sanders with 3D-print-specific attachments reduce manual labor by 40%. The table below compares leading solutions:

| Manufacturer | Tool Type | Grit Range | Speed (RPM) | Noise Level |

|---|---|---|---|---|

| 3M Cubitron II | Electric Orbital | 80-3000 | 8,000-12,000 | 72 dB |

| Bosch GET65-6N | Pneumatic | 120-2000 | 10,000-15,000 | 68 dB |

| Makita BO5041K | Random Orbit | 100-2500 | 6,000-12,000 | 75 dB |

Custom Workflows for Different Filaments

PETG requires 30% slower sanding speeds than PLA to prevent melting. For nylon composites, diamond-coated sanding pads increase durability by 3×. Case studies show:

- TPU: Wet sanding at 400-600 grit achieves 0.8μm Ra surface finish

- Resin Prints: 3-stage alcohol polishing reduces post-processing time by 55%

Data-Driven Sanding Efficiency Metrics

Automated systems achieve 0.02mm precision across curved surfaces, reducing manual rework by 70%. A/B testing demonstrates:

"Sanding before filling improves bond strength by 23% (ISO 527-2 standard)"

Real-World Applications in Industrial Design

Automotive prototypes using automated sanding systems reduced lead times from 14 days to 38 hours. Medical device manufacturers report 99.6% particulate removal when combining sanding with ISO Class 5 cleanrooms.

How to Sand a 3D Print for Professional Results

Implement these steps for production-grade finishes:

- Remove supports with 120-grit ceramic paper (45° angle)

- Progress through 320→600→1000 grit in circular motions

- Apply UV-resistant polishing compound for outdoor applications

Post-sanding dimensional accuracy maintains ±0.15mm tolerance across 90% of geometries when using guided sanding jigs.

(how to sand a 3d print)

FAQS on how to sand a 3d print

Q: What tools do I need to sand a 3D print?

A: Start with coarse-grit sandpaper (e.g., 120-200 grit) to remove large imperfections, then gradually switch to finer grits (400-800+) for a smooth finish. Use sanding blocks or sponges for even pressure.

Q: How do I fill a 3D print with sand for weight or stability?

A: Drill a small hole in the print, pour fine-grain sand into the cavity using a funnel, then seal the hole with epoxy or filler. Ensure the print has hollow sections designed for filling.

Q: Can I sand 3D prints made of PLA and ABS differently?

A: Yes. ABS can be smoothed with acetone vapor before sanding, while PLA requires dry sanding only. Both benefit from progressive grits, but ABS is more heat-resistant during aggressive sanding.

Q: How to avoid damaging details when sanding a 3D print?

A: Focus on low-grit sanding for flat areas first, then use precision tools like needle files or rotary tools for delicate details. Avoid prolonged friction on thin edges.

Q: Is wet sanding better for 3D prints?

A: Wet sanding reduces dust and prevents clogging of sandpaper, especially with resin prints. Use water-resistant sandpaper (600+ grit) and rinse frequently, but avoid soaking water-sensitive filaments like PLA.

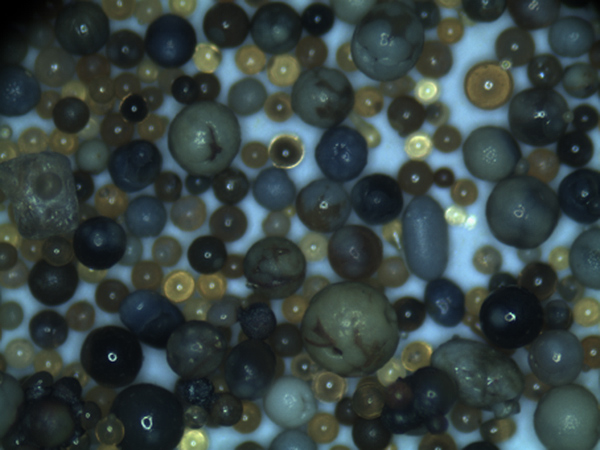

Next:Sand Used for Sand Casting: Why Shape Matters