Modern advancements have significantly enhanced the precision and efficiency of this technique

Modern advancements have significantly enhanced the precision and efficiency of this technique

Modern advancements have significantly enhanced the precision and efficiency of this technique

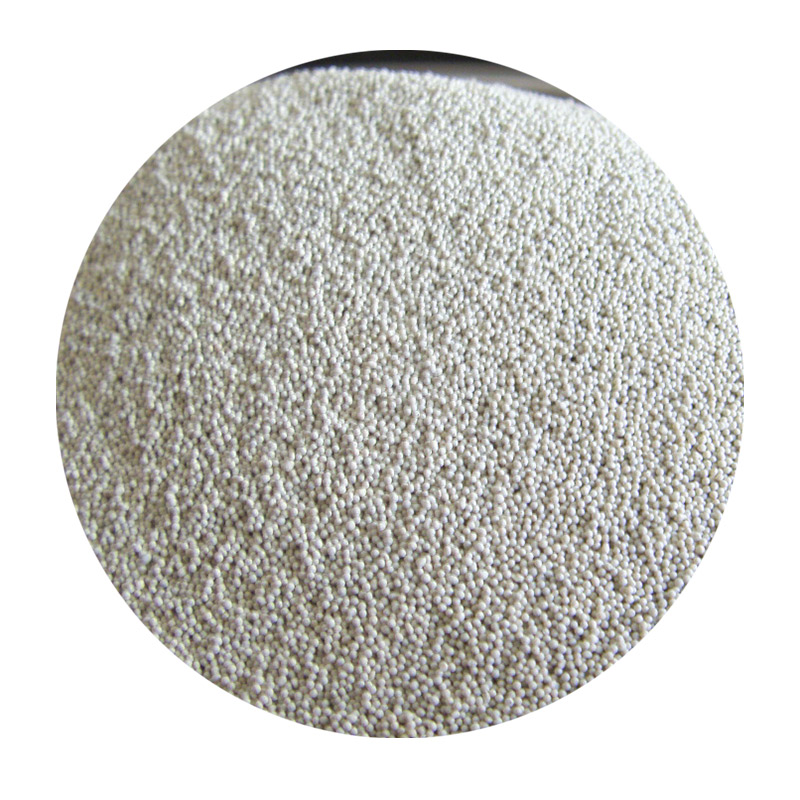

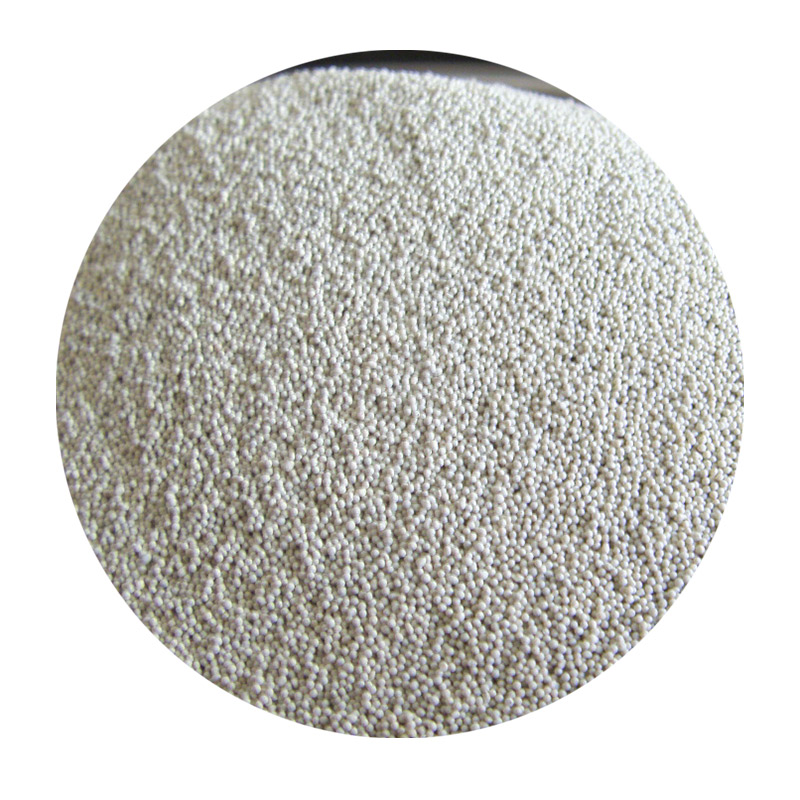

Modern advancements have significantly enhanced the precision and efficiency of this technique precision sand casting. Computer-aided design (CAD) and computer-aided manufacturing (CAM) enable the creation of complex patterns with minute details, while automated molding machines streamline the process, reducing errors and increasing productivity. Furthermore, the use of advanced metallurgical techniques allows for better control over the metal's properties, ensuring consistent quality in each cast.

Despite its seeming simplicity, precision sand casting requires a deep understanding of metallurgy, mold-making, and foundry operations. Skilled artisans and engineers work in tandem, combining their expertise to produce components with unparalleled precision and durability. It is a process that combines artistry, science, and craftsmanship, reflecting the human touch in a world increasingly dominated by automation.

In conclusion, precision sand casting is more than just a manufacturing process; it's a testament to our ability to harness natural resources and technological innovation to create objects of precision and beauty. As we continue to refine this technique, the possibilities for creating intricate, high-quality metal parts seem virtually limitless. From the smallest gears to the largest engine blocks, precision sand casting remains an indispensable tool in the global manufacturing landscape.

Post time:Jun . 30, 2024 10:40

precision sand casting. Computer-aided design (CAD) and computer-aided manufacturing (CAM) enable the creation of complex patterns with minute details, while automated molding machines streamline the process, reducing errors and increasing productivity. Furthermore, the use of advanced metallurgical techniques allows for better control over the metal's properties, ensuring consistent quality in each cast.

Despite its seeming simplicity, precision sand casting requires a deep understanding of metallurgy, mold-making, and foundry operations. Skilled artisans and engineers work in tandem, combining their expertise to produce components with unparalleled precision and durability. It is a process that combines artistry, science, and craftsmanship, reflecting the human touch in a world increasingly dominated by automation.

In conclusion, precision sand casting is more than just a manufacturing process; it's a testament to our ability to harness natural resources and technological innovation to create objects of precision and beauty. As we continue to refine this technique, the possibilities for creating intricate, high-quality metal parts seem virtually limitless. From the smallest gears to the largest engine blocks, precision sand casting remains an indispensable tool in the global manufacturing landscape.

Post time:Jun . 30, 2024 10:40

Next:Evaluating the Economics of Sand Casting Process A Cost Analysis