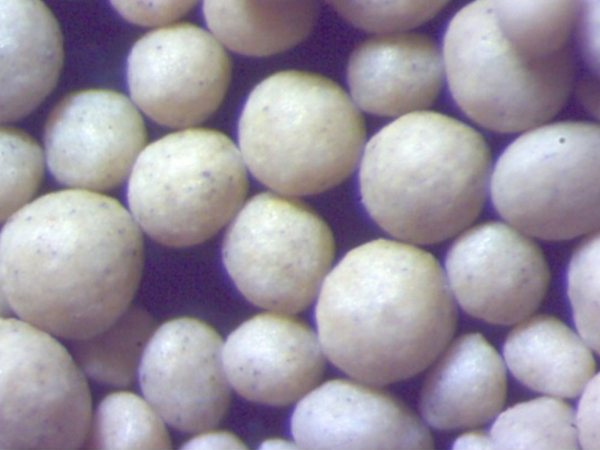

Its advantage lies in its simplicity and economy but may lack the dimensional accuracy required for intricate castings Its advantage lies in its simplicity and economy but may lack the dimensional accuracy required for intricate castings

Its advantage lies in its simplicity and economy but may lack the dimensional accuracy required for intricate castings Its advantage lies in its simplicity and economy but may lack the dimensional accuracy required for intricate castings sand used in foundry.

- **Resin-Bonded Sand** Resins, either furan or phenolic, when mixed with sand and catalysts, create a stronger, more stable mold. They offer faster production cycles, improved surface finish, and dimensional accuracy, albeit at a higher cost.

- **CO2 Process** In this modern approach, sand is bonded using a binder that hardens upon exposure to CO2 gas. It combines the speed of resin-bonded systems with environmental benefits, as the binder breakdown products are inert and recyclable.

**Recycling and Environmental Considerations**

Given the sheer volume of sand consumed in foundries, recycling has become imperative both economically and environmentally. Spent sand, after casting, can often be reclaimed through sieve separation, thermal reclamation, or mechanical attrition to remove binders and contaminants. Recycled sand, though it may require with fresh sand to maintain quality, significantly reduces waste and resource consumption.

**Advancements and Future Perspectives**

The foundry industry continually explores innovations to enhance efficiency, sustainability, and product quality. Research into new binding systems that are more eco-friendly and efficient reclamation technologies are at the forefront. Additionally, digitalization, including 3D printing of sand molds, promises greater design flexibility, reduced waste, and faster prototyping, ushering in a new era for sand casting.

In conclusion, sand, in its various forms and applications, remains a cornerstone of foundry operations. Its adaptability, combined with evolving technologies and sustainable practices, ensures that this age-old manufacturing process continues to thrive in the modern industrial landscape. As we look to the future, the ongoing quest for optimization and innovation underscores the enduring significance of sand in foundry processes.

Post time:Jun . 25, 2024 01:32

sand used in foundry.

- **Resin-Bonded Sand** Resins, either furan or phenolic, when mixed with sand and catalysts, create a stronger, more stable mold. They offer faster production cycles, improved surface finish, and dimensional accuracy, albeit at a higher cost.

- **CO2 Process** In this modern approach, sand is bonded using a binder that hardens upon exposure to CO2 gas. It combines the speed of resin-bonded systems with environmental benefits, as the binder breakdown products are inert and recyclable.

**Recycling and Environmental Considerations**

Given the sheer volume of sand consumed in foundries, recycling has become imperative both economically and environmentally. Spent sand, after casting, can often be reclaimed through sieve separation, thermal reclamation, or mechanical attrition to remove binders and contaminants. Recycled sand, though it may require with fresh sand to maintain quality, significantly reduces waste and resource consumption.

**Advancements and Future Perspectives**

The foundry industry continually explores innovations to enhance efficiency, sustainability, and product quality. Research into new binding systems that are more eco-friendly and efficient reclamation technologies are at the forefront. Additionally, digitalization, including 3D printing of sand molds, promises greater design flexibility, reduced waste, and faster prototyping, ushering in a new era for sand casting.

In conclusion, sand, in its various forms and applications, remains a cornerstone of foundry operations. Its adaptability, combined with evolving technologies and sustainable practices, ensures that this age-old manufacturing process continues to thrive in the modern industrial landscape. As we look to the future, the ongoing quest for optimization and innovation underscores the enduring significance of sand in foundry processes.

Post time:Jun . 25, 2024 01:32

Next:Sand Casting Suppliers Premium Quality Materials for Your Castings Needs