The Importance of Foundry Molding Sand in Metal Casting

Foundry molding sand is a crucial material used in the metal casting industry, providing the necessary properties for creating complex shapes and high-quality metal castings. The preparation and selection of molding sand can significantly influence the efficiency of the casting process and the properties of the final product. This article explores the various types of foundry molding sands, their characteristics, and the critical role they play in metal casting.

Types of Foundry Molding Sand

The primary types of foundry molding sand include green sand, resin-bonded sand, and shell sand

.1. Green Sand This is the most commonly used type of molding sand in foundries. Green sand is a mixture of silica sand, clay, water, and other additives. Its moisture content and clay content help in binding the sand grains together, providing the necessary strength and flexibility during the molding process. Green sand is particularly favored for its ability to produce detailed castings with a smooth surface finish.

2. Resin-Bonded Sand This type of sand uses synthetic resins as a bonding agent instead of clay. Resin-bonded sands can achieve greater strength and thermal stability compared to green sand. They are often used for producing intricate parts with better dimensional accuracy. The resin provides a faster setting time, making it ideal for high-volume production environments.

3. Shell Sand Shell molds are created by covering a pattern with a mixture of fine sand and a thermosetting resin. When heated, the resin hardens, forming a shell that can be used for metal casting. This technique yields excellent surface finish and high dimensional accuracy, making shell sand suitable for parts requiring intricate details.

Properties of Foundry Molding Sand

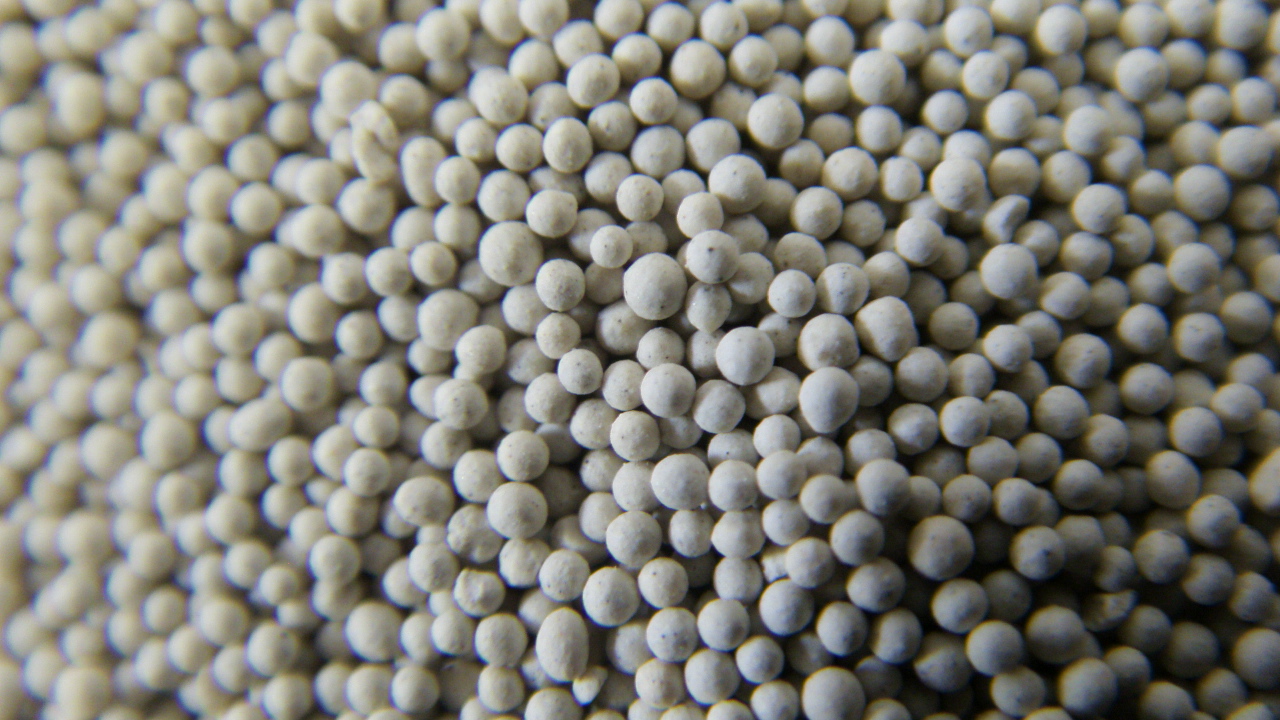

foundry molding sand

The effectiveness of molding sand depends on several critical properties, including

- Grain Size The grain size of the sand affects the surface finish of the casting. Finer sand provides smoother surfaces but may limit the ability to create larger voids. Coarser sand, on the other hand, can create larger molds but at the cost of surface finish quality.

- Permeability This property refers to the sand's ability to allow gases to pass through during the casting process. Good permeability is essential to prevent defects such as gas holes in the casting. Green sand typically offers good permeability, while resin-bonded sands may require careful preparation to maintain this property.

- Thermal Stability The ability of molding sand to withstand high temperatures without breaking down is critical in metal casting. Sands with high thermal stability reduce the risk of mold deformation and ensure the integrity of the mold throughout the casting process.

The Role of Molding Sand in Quality Control

Quality control in metal casting starts with the selection of the right molding sand. A carefully formulated sand mix can decrease the likelihood of casting defects such as shrinkage cavities, inclusions, and surface imperfections. By monitoring and adjusting the properties of molding sand, foundry operators can enhance the overall performance of the casting, leading to higher yields and lower production costs.

In conclusion, foundry molding sand is an essential component of the metal casting process. Understanding the different types of molding sands, their properties, and their roles can help foundries produce high-quality castings more efficiently. As technology advances, the development of new sand types and binding agents will likely continue to enhance the metal casting industry, improving product quality and production capabilities. Therefore, ongoing research and innovation in foundry molding sands remain vital for the future of metal casting.

Post time:Aug . 13, 2024 20:31

Next:Detailed Overview of Foundry Sand Specifications for Optimal Casting Performance and Quality