Understanding Sand Casting with Resin A Comprehensive Guide

Sand casting is a versatile and cost-effective manufacturing process widely used for producing metal parts and components. In this process, sand is the primary material used to create molds. The introduction of resin into the sand casting process has further enhanced its capabilities, leading to improved quality, strength, and surface finish of the final products. In this article, we will explore the concept of sand casting with resin, its advantages, applications, and considerations.

What is Sand Casting?

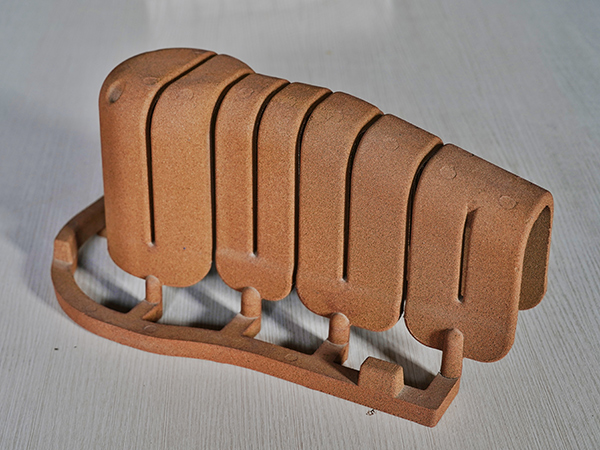

Sand casting involves creating a mold from a mixture of sand and a binding agent, usually clay, to form shapes. The mold cavity is created by compacting the sand around a pattern, often made of metal or wood, and then removing the pattern once the sand has set. Molten metal is then poured into the mold, allowed to cool, and solidify, after which the mold is broken away to reveal the cast part.

The Role of Resin in Sand Casting

Resin sand casting, also known as resin-bonded sand casting, replaces traditional clay binders with chemically hardened or thermosetting resins. This innovation offers several benefits

1. Improved Surface Finish Resin sand produces molds with a smoother surface compared to traditional sand molds. This quality results in parts that require less machining and have better aesthetic appeal.

2. Higher Mold Strength The resin enhances the strength and integrity of the mold, allowing it to hold up under the high temperatures of molten metal. This strength reduces the likelihood of defects and improves the overall quality of the castings.

3. Complex Geometries Resin sand can better capture intricate designs and features in the mold, enabling manufacturers to create complex shapes that might be challenging with traditional sand casting methods.

4. Reduced Production Time The quick setting time of resin allows for faster mold production, leading to a more efficient casting process. This speed is particularly beneficial in high-volume manufacturing settings.

sanding casting resin

5. Environmental Considerations Many modern resin systems are designed to be environmentally friendly, helping manufacturers comply with increasingly strict regulations.

Applications of Resin Sand Casting

Resin sand casting finds applications across various industries. It is commonly used in

- Automotive Production of engine blocks, cylinder heads, and transmission cases, where precision and strength are crucial. - Aerospace Manufacturing lightweight yet durable components that can withstand extreme conditions. - Heavy Equipment Creating parts for machinery and equipment that require robust construction and reliability. - Art and Sculpture Artists and sculptors utilize resin sand casting to produce intricate designs and artistic pieces.

Considerations and Challenges

Despite its many advantages, there are considerations to keep in mind when using resin in sand casting

- Cost The initial investment in resin materials and equipment may be higher than traditional sand casting. - Process Control Careful monitoring of the mixing, curing, and pouring processes is essential to avoid defects and ensure quality control. - Health and Safety While modern resins are designed to be safer, proper handling and ventilation are important during the casting process to minimize exposure to potentially hazardous materials.

Conclusion

Resin sand casting represents a significant advancement in the field of foundry operations, offering numerous advantages over traditional methods. The combination of improved surface finish, mold strength, and the ability to produce complex geometries makes it an attractive option for various industries. As technology continues to evolve, the use of resin in sand casting is likely to become even more prevalent, pushing the boundaries of what can be achieved in metal casting and opening new opportunities for innovation and creativity.

Post time:Aug . 10, 2024 14:05

Next:A Step-by-Step Guide to Casting Sand into Resin for Unique Art Projects